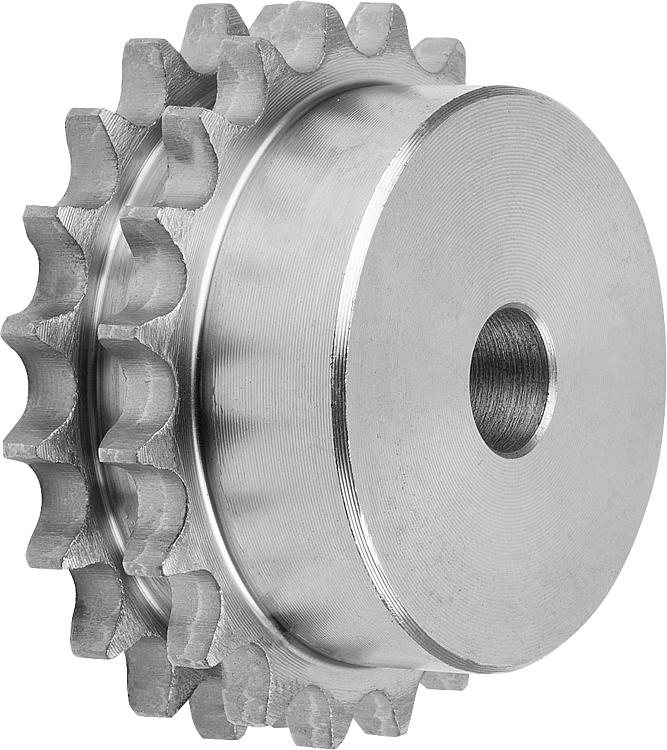

What is Sprocket? 18 Types of Sprockets, Uses & Pitch Diameter [with Pictures]

![What is Sprocket? 18 Types of Sprockets, Uses & Pitch Diameter [with Pictures]](https://engineeringlearn.com/wp-content/uploads/2021/12/Sprocket-1024x539.jpg)

What is Sprocket?

Types of Sprockets and Their Uses (Pitch Diameter) :- A sprocket is referred to as a wheel which is found with teeth, cogs or even sprockets that are found having a mesh with the holes in the links of chain, track or other perforated material. A sprocket is considered to be different from a gear as the sprocket is found to never mesh directly with another sprocket. Sprockets are usually designed in order to be used along with a specific chain. Selecting the right sprocket is responsible for optimizing the sprocket or the chain interaction which ensures the proper performance of the drive and also decreases its maintenance at the same time.

Classification of Sprockets

Sprockets are found to be basically characterized by the type which is indicates the hub style:

Type A

These are the type of sprockets which are found to be flat and also do not have any hub. These are usually the ones which are mounted on the flanges or hubs of the device, by which they are driving through a series of holes that are found to be plain or tapered.

Type B

These are referred to as those sprockets which have a hub on one side that allows the sprocket in order to be fitted closely to let the machinery on which it is mounted. This is responsible for eliminating a large overhung load on the bearings of the equipment.

Type C

These are known to be the types of sprockets which are extended on both the sides of the plate and are usually used on the driven sprocket where the pitch diameter is found to be larger and where there is more weight to support on the shaft. The larger is the load, the larger would be the hub.

Type D

These are the type of sprockets which are found using a type A sprocket that is mounted on a solid or split hub. Speed ratio is found to be changed without having remove the bearings and other equipment.

Different Types of Sprockets

Following are the main types of sprockets:

- Chain sprockets

- Industrial sprockets

- Duplex sprockets

- Shaft sprockets

- Drive sprockets

- Triplex sprockets

- Idler sprockets

- Simplex sprockets

- Drum sprockets

- Steel split sprockets

- Single Strand Sprockets

- Multi-strand sprockets

- Bushed sprockets

- Taper-lock sprockets

- Quick disconnect sprockets

- Double plus sprockets

- Double pitch sprockets

- Double single sprockets

1. Chain Sprocket: ( Types of Sprockets )

These are referred to as one of the most common type of sprockets which are found being used. They are found working only with the chains which are designed by the rollers that are interconnected by the pins. Roller chains are found providing a gap that fits the teeth of the sprocket in order to transfer the rotary motion.

2. Industrial Sprocket: ( Types of Sprockets )

The industrial sprockets are found to be popularly made of graded stainless steel, mild steel and cast iron as they are responsible for giving high tensile strength as well as efficiency. These are various different types of sprockets which are found to be manufactured by their originators in order to achieve greater efficiency.

3. Duplex Sprocket: ( Types of Sprockets )

The duplex sprockets are found to be the ones which are usually made of mild steel and are sometimes of stainless steel in various different sizes. It can be either a single hub or a double hub as per the required specifications. And the induction is found to be the hardened teeth where the duplex sprockets are found to be available.

4. Shaft Sprocket: ( Types of Sprockets )

Shaft sprocket is the type of sprocket which is found to be made of welded steel. These are known to be those sprockets which are either in one piece or are formed with a replaceable tooth segments for the drive and tail sections. Shaft sprockets are referred to as the ones which are commonly used for the purpose of handling the ash applications. These are the types of sprockets which are found to be available with various numbers of teeth or hub designs.

5. Drive Sprocket: ( Types of Sprockets )

The drive sprockets are referred to as one of the most common type of sprockets which are usually provided with shaft import power. They are mostly found to be available with a smaller diameter.

6. Triplex Sprocket: ( Types of Sprockets )

The triple sprocket is referred to as a triple 18 tooth taper which is known as the bushed type sprocket that is found using bushing. These are referred to as the sprockets which are responsible for being constructed by the help of a high-quality mild steel and are thus fabricated with high precision tolerances for optimum long-term performance.

7. Idler Sprocket: ( Types of Sprockets )

Idler sprocket is referred to as that sprocket which is used where the long lengths can cause chain slack. These are some of the types wherein there are a non-adjustable drive shaft, or a chain is guided around an obstacle. The use of an idler sprocket is found stopping the chain whipping and uneven load distribution.

Idler sprockets are used where the chain may experience slack due to long lengths, where there is a non-adjustable drive shaft, or wherever the chain is found being guided around any obstruction. The usage of idler sprockets prevents the chain whipping and uneven load distribution.

8. Simplex Sprocket: ( Types of Sprockets )

Simplex sprockets are defined as the ones which are found to be divided using a gear in which the sprocket is not at all joined directly together, and in that, it is separated by a pulley. These are the sprockets which are found to be commonly made of teeth and smooth pulleys.

9. Drum Sprocket: ( Types of Sprockets )

These sprockets are referred to as the stronger and thicker sprockets which focuses on reducing the contact pressure through the increased surface area. Drum sprockets are referred to as the ones which are used for heavy-duty and industrial applications.

10. Steel Split Sprocket: ( Types of Sprockets )

Several sprockets are required in order to loosen the chain, by putting the sprocket, and tightening the chain again. The steel-split sprocket consists of two parts which are split through the Centre and are thus bolted back together which can help in easy fitting into a system.

Steel split sprockets are referred to as those which are found to split through the entire radius for easy installation as well as removal. The halves are found to be held together using the bolts.

11. Single Strand Sprocket

12. Multi Strand Sprocket: ( Types of Sprockets )

Multi-strand sprockets are the ones which are specifically used wherever there is high torque and power are required, or two or more than two items are being driven by a drive shaft. These are available with approximately 40 to 160 chain pitches with plain, finished, taper-locked, or QD style hubs.

Multi-strand sprockets are referred to as those which are used where the higher torque along with the power is needed, or wherever there are two or more items which are being powered by a common drive shaft. Multiple strand sprockets are the ones which are found to be available in 40 through 160 chain pitch accompanied with plain, finished, taper-lock, or QD style hubs.

13. Bushed Sprocket: ( Types of Sprockets )

Bushed sprocket are referred to as those sprockets which are found providing support, like the anchor bolts, in order to assure that the flange is found holding the sprocket. All the heavy lifting industry systems are found to often require bushing sprockets.

14. Taper Lock Sprocket: ( Types of Sprockets )

Taper lock sprockets are referred to as those sprocket which are used as a split through the taper and flange in order to give a clamp on the shaft. The taper-lock bushing is found to be held in place with the set screw on the sprocket.

Taper-lock sprockets are the ones which are found utilizing a split through the taper and flange in order to provide a true clamp on the shaft. A Taper-Lock bushing is found to retain to the sprocket along with the set screws. These also offer flexibility at the same time by allowing multiple sized bores for a single bushing size.

15. Quick Disconnect Sprocket: ( Types of Sprockets )

Quick disconnect sprocket are referred to as those sprockets which are found being used in the high working load and high clamp loading on the shaft. QD sprockets are known to be the ones which are usually flanged along with the anchor bolts around the perimeter.

QD sprockets are referred to as those sprockets which are mainly used where there is higher working loads and high clamp loading on the shaft is desirable. These are the types of sprockets which are commonly found to be flanged and also use some of the anchor bolts which are found around the circumference. Sprockets accompanied with the tapered bushings are the ones which are found easy to install as well as remove, provided clamp force, and align the sprocket.

16. Double Plus Sprocket: ( Types of Sprockets )

Double Plus sprocket are the ones which are specifically designed along with the double plus chain. These are referred to as those sprockets which are used in the conveyor applications wherever the product is moving at high speed to power the conveyor.

Double plus sprockets are referred to as those sprockets which are specifically designed in order to be used accompanied with a Double Plus chain and is in conveyor applications wherein the product is moving at twice the speed of the drive system which powers the conveyor. The benefits of such type of sprockets include less noise and a longer chain life.

17. Double Pitch Sprocket: ( Types of Sprockets )

These are the types of sprockets which are considered to be quite similar to the standard sprockets other than the half the number of teeth. These are the sprockets which are found to be used along with a small roller double pitch chain in order to accommodate the longer distances within the rollers. There are various types of chain sizes which are found to be used commonly in the industries and are also known for their larger diameters.

18. Double Single Sprockets: ( Types of Sprockets )

Double single sprockets are referred to as those which are found to be used in the applications where two or more items are responsible being powered by a common drive shaft. One strand may exit in a different direction as compared to the other.

Application of Sprocket

There are various types of sprocket and chain assemblies. Each type of the drives are found to be of varying types of machinery which are found running on the movement in various applications and industries. For instance, sprocket assemblies are the ones which are found in the following applications:

- Agricultural and farming equipment

- Automotive equipment

- Vehicles, such as bicycles and motorcycles

There are many different sprocket types which include some of the below mentioned types:

1. Roller Chain

Roller chain sprockets referred to as those which are found to be one of the most common type of sprocket. They are the ones which operate along the chains which are formed by rollers that are interlinked by the pins. These are known as the chains which are found responsible for forming the gaps within the sprocket’s teeth that gets fitted into it so that the transfer movement of energy is found possible. These are some of the most frequently used chains in transmission of equipment.

2. Single-Pitch And Double-Pitch

Single-pitch sprockets are referred to as those which are found having spaced teeth that allows the chain’s roller pins to fall into every tooth. The double-pitch sprockets are found having teeth which are spaced so the pins fall into every other gap. These are used in the conveyor systems which are found requiring precise product placement.

3. Smart Tooth Sprockets

Tsubaki’s patented wear indicator sprockets are referred to as the smart tooth sprockets which are found having wear indicator pins on either one or more sprocket teeth. Smart tooth sprockets are the ones which are found saving the chain from breaking as it is responsible for providing the ability to identify and to schedule the maintenance of the drive system before any critical component failure is found to occur.

4. Drum

Drum sprockets are referred to as those which are found having thick sprockets that focus on lowering contact pressure through increased surface area. These sprockets are renowned for the heavy-duty and industrial applications.

5. Steel-Split

Many sprockets are found having installed through slackening the chain, which places the sprocket, and then retightens the chain. Whereas mainly these types of sprockets are usually the ones which are found having at least two different as well as separate parts which are found to be split through the center and are then bolted back together, in order to facilitate easier installation into an existing system.

6. Idler

If a system is found having a long chain, then it can surely become slack around the non-adjustable shafts or in long routes of the chain around the obstructions. These are referred to as those idler sprockets which are found responsible for preventing uneven load distribution along with the chain and can also stop any potential chain whipping.

7. Bushed

These systems are referred to as the ones which are found having additional supports, like the anchor bolts in order to ensure that the flange is found to stick to the sprocket. The industry systems are found to be those which are found conveying entire heavy loads that are found to be required as the bushed sprockets.

Pitch Diameter of Sprocket

For the Chain

In this type of pitch diameter, the pitch is referred to as that measurement of a chain which is calculated from the Centre of the roller-pin to the roller-pin. This type of measurement is found quite similar in order to measure the distance within the interlinking points on a chain.

For the Sprocket

Sprocket diameters are the ones which are easily found to be measured in three ways:

Outside diameter – which is usually measured from the highest point of the sprocket teeth.

Pitch diameter – which is found to fall within the two wherein the teeth bites into the chain. This is the measurement which dictates if a sprocket is a good fit for the pieces of the matching chain.

Bottom diameter –

Number of Strands

Strands are referred to as the rows of teeth which are found along a sprocket’s circumference. Many common sprockets are found to be single strand. Other sprockets can have either double or triple sprockets which can grab onto either two or three chains at once. Multi-strand chains are found to be driving greater torque and power from a common central shaft.

Caliper Diameter

The caliper diameter is found to be quite similar to the bottom diameter. It is responsible for measuring the diameter across the sprocket’s plate without including the teeth. As soon as the operators are found to be replaced with the sprockets with any of the worn and broken teeth, then the diameter of the caliper may be the only way by which one can identify the dimensions of the sprocket.

Hub Diameter

The hub diameter is found responsible in order to measure the diameter of the hub wherein the additional thickness accompanied with the plate around the central bore on Type B and Type C sprockets needs to be considered.

Length-Through-Bore (LTB)

This is referred to as the thickness of the sprocket which can be measured from the outside edge of the hub to the outside edge of the opposite hub through the central bore in Type C sprockets. This is responsible for determining the actual length of the rotating shaft.

Tooth Pitch

Sprockets are found having wide or narrow teeth which depends on the length of the pitch in the chains which are found to be matched. Chains accompanied with the large pitch diameter are usually the one which are found to be in demand sprockets that are similarly large teeth, whereas the chains along with the smaller lengths are found within the roller-pin centres that need to have smaller teeth. Tooth pitch is the one which refers to the number of teeth per inches.

Bore Size

The sprocket bore is referred to as that wherein the hole through the center of the sprocket is responsible for the drive shaft runs. To let the calculation of the diameter of the shaft correctly, one must ensure that the selected sprocket does not have a sprocket bore which is too small or too large in order to fit without tilting or slipping.

Number of Teeth

The total number of teeth on a sprocket are found to be an important measurement. The tooth pitch are one of the must measurements which are compulsorily selected so that the sprocket gets the right fit for the chain’s pitch and the equipment itself.

Additional Options

There are factors beyond the size and the number of teeth which are found to be just as important when selecting new sprockets. The metal sprockets are the ones which are found being heat treated and hardened in order to withstand extreme operating conditions.

To know the accurate specifications of the chain as well as the sprocket within a system, one can ensure that the right replacement parts are designed as well as fabricated at first time only. In order to let the right parts be the components and to also let them connected equipment safer from shutdowns, overloading, and slippage.

Technical Terms

- Sprocket Hub Style: Sprocket hub styles are found having A, B, and C style hub configurations which are mostly offered by various international manufacturers.

- Sprocket Caliper Diameter: This is responsible for measuring the diameter of the sprocket plate without the teeth.

- Sprocket Outside Diameter (OD): The outside diameter is measured from the tooth peak of the sprocket to the tooth peak of the sprocket on the opposite side. This is referred to as the sprocket outside diameter.

- Length Through Bore (LTB): The measurement of the inside hub diameter accompanied along with the length to which it was to be machined. The length needs to be accommodated as per the proper size keyway to withstand shear and torque stress.

- Plain Bore: Plain bore is the one which is determined towards the inside diameter of the hub and is thus machined along with a standard keyway and two set screws.