3 Types of Condenser – Introduction, Components, Working, Advantages & Disadvantages [Complete Explained]

![3 Types of Condenser - Introduction, Components, Working, Advantages & Disadvantages [Complete Explained]](https://engineeringlearn.com/wp-content/uploads/2022/10/Condenser-1024x734.jpg)

What is a Condenser?

Types of Condenser – Introduction, Components, Working, Advantages & Disadvantages [Complete Explained]: – The condenser is a type of heat ex-changer gadget, where vaporous substances are compressed into a fluid state utilizing a cooling agent and, then, at that point, latent heat is released in the climate, known as a condenser.

Condenser (heat move) is a gadget or unit used to consolidate vapor into a fluid. Explicit types include HVAC air curls. Condenser (research center), a range of laboratory sets used to remove heat from fluids.

How Does a Condenser Work?

We should have a concise look at how a condenser functions. Once more, we need to specify that a full description of the part was committed to the subject of elements of a condenser. We convey the significance of how a condenser works to make it easier for you to comprehend what various kinds of this equipment are.

Three different phases happen in every condenser. The first phase is called desuperheating. The vapor going into the condenser is already superheated and super-compressed in the evaporator and compressor. Desuperheating means ejecting the heat and intensity from the vapor and transform it into liquid. The next level is changing or condensation state; losing more heat continues in this state where we reach 10% of refrigerant as vapor and 90% as a liquid.

The third and last stage is a sub-cooling state. The sub-cooling state is there in order to be certain that not, in any event, rising temperatures can bring the liquid refrigerant into vapor again.

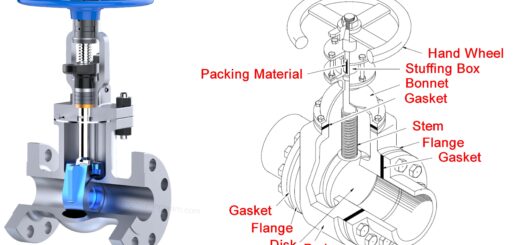

Components of Condenser

Here are the primary parts of the condenser.

- Shell – Shell is the external surface and base of the condenser.

- Tubes – Tubes are the primary part of the condenser, through that fume or gas is passed.

- Cooling Agent – Cooling specialist To Create Temperature distinction and to ingest fume temperature, a Cooling specialist is required.

- Coolant Gulf – Coolant delta A Place, from where the coolant is placed into shell.

- Coolant Outlet – A Place, Where Used coolant is dropped from the shell.

- Fume Inlet – A spot, where High-temperature fume is placed into the cylinders.

- Condensate Outlet – A spot, Where the dense fluid is dropped from the cylinder.

- Non-consolidating Fume Outlet – A Place, Where Non-gathering fume is cruised by.

Types of Condenser

1. Air-Cooled Condenser: ( Types of Condenser )

This type of Condensers uses air as the outer fluid to reject the heat and intensity from the framework. Air-cooled condensers normally have copper coils where refrigerant streams in. But this is not the whole story; this type is sub-categorized into two subsets: natural convection and forced convection.

A) Forced Convection

One of the different types of condensers is constrained convection. A fan or a blower expects the most critical part in eliminating heat from the refrigerant inside the coils. The fan blows the air into the finned coils and loops. An important tip has to be noted here and it is that the fins of forced convection condenser are put tightly next to each other; so, assuming the residue and dirt fill the slight space between the balances, the air flowing and heat rejection faces big difficulty.

Forced and Constrained convection type condensers are normally utilized in window air control systems, water coolers, and packaged air conditioning plants.

B) Natural Convection

In this sort of condenser, air comes to contact with warm coils, absorbing the heat of refrigerant inside the coils, subsequently the temperature of air increases. As the warm air is lighter, it goes up and the cold air replaces and again the cold air comes to touch warm coils to reject the heat and intensity. This natural cycle goes on until the refrigerant loses its heat.

Since the flow rate of air is small and the radiation heat transfer is likewise not extremely high, the consolidated heat transfer coefficient in these condensers is small. Subsequently, a relatively large condensing surface is required to reject a given amount of heat and intensity. Consequently, these types of condensers are utilized for small capacity refrigeration frameworks like household refrigerators and freezers.

2. Water-Cooled Condenser: ( Types of Condenser )

This type or sort of condenser involves water as liquid to eliminate heat from the refrigerant. Clearly, water-cooled condensers are utilized where we have an adequate supply of water. This type, itself has three different kinds:

A) Double Tube

Double Tube condensers have a tube of water inside a huge refrigerant tube or cylinder. The water retains the majority of the refrigerant heat and intensity, however as the refrigerant tube is in touch with the natural dissemination of air, some portion of the cooling system is on natural convection. Albeit double tube condensers commonly have been utilized in past, the large number of gaskets and flanges utilized in these heat exchangers prompts maintenance issues.

B) Shell and Tube Condensers

One of the sorts or types of condensers plays out the process of rejecting heat by having a cylindrical shell comprising of water tubes. In a shell and tube condenser, water is pumped through the pipes while refrigerant flows or streams in the shell. Installment of fins in pipes permits better heat transfer. The shell-and-tube condensers are by and large low in cost and simple to maintain.

The most widely recognized type of shell and tube condensers is the flat shell type. In any case, vertical shell and tube condensers are typically utilized with ammonia in enormous capacity frameworks so that cleaning of the tubes is conceivable from the top while the plant is running.

C) Shell and Coil condensers

A welded shell contains a curl of finned water tubing in a shell-and-coil condenser. In this sort of water-cooled condenser, the hot refrigerant flows in the shell while the cooling water circulates inside the coils and condenses the refrigerant. It is all-around compact and low in cost.

3. Evaporative Condenser: ( Types of Condenser )

The last one of the type of condenser is the evaporative one. Evaporative condensers use air and water as the consolidating medium. The condenser’s sump pumps the water to be showered over coils and simultaneously, a fan blows the air into the condenser. The sprayed water over the coil evaporates and the necessary heat and intensity for the vaporizing water are taken from the heat of the refrigerant. Some amount and measure of water will be circulated by dropping into the sump however to make up the amount dissipated, an additional measure of water is added to the water supply of the sump.

Where there is Water scarce, Evaporative condensers are utilized. Since water is utilized in a closed-loop, just a little piece of the water vanishes. Make-up water is provided to deal with the evaporative misfortune. The water utilization is commonly exceptionally low, around 5% of the same water-cooled condenser with a cooling tower. Nonetheless, since the condenser must be kept outside, this sort of condenser requires a more extended length of refrigerant tubing, which calls for bigger refrigerant stock and higher strain drops.

Comparison Between These Three Types

- Evaporative are frequently less expensive compared to water-cooled requiring a cooling tower.

- Evaporative are utilized where we generally experience a water supply shortage.

- Evaporative are kept outside, so in chilly seasons, the water pump is switched off in order to forestall freezing water.

- Air-cooled condensers contrasted with water-cooled ones are straightforward in development. In addition, admittance to air is generally accessible.

- The support and maintenance cost of an air-cooled is low in comparison with a water-cooled. Also, water-cooled types of condensers are more complex than air-cooled condensers as there are design contemplations in water flow guideline and avoidance of corrosion.

- Notwithstanding, the Benefits of water-cooled frameworks are that water has a higher exchange coefficient than air so heat transfer will be more proficient.

Advantages of Condenser

- It builds the extension proportion of steam, and subsequently increases the productivity of the plant.

- It lessens the back pressure of the steam, and subsequently, more work can be acquired.

- It lessens the temperature of the exhaust steam, and it increases the work proficiency.

- The reuse of condensate as feed water for the boilers lessens the expense of power generation.

- The temperature of the condensate is higher than that of the freshwater, therefore, how much intensity provided per kg of steam is diminished.

- Helpful in Obtaining the better vacuum

Disadvantages of Condenser

- Need an adequate supply of Freshwater.

- It isn’t easy to repair, hence you should watch out and need to be careful

- Corrosion.

- Requires more space.

- Maintenance cost is extremely high, so Always keep your budget plan tight.

Conclusion

The petrol and chemical industries utilize condensers for the buildup of hydrocarbons and other substance fumes. The arrangement of a condenser expands the capital cost of the power plant. Since it needs a condenser, the allied pump to work or operate the condenser, the hot well, and the cooling tower. In any case, the increased capital expense is counterbalanced in an extremely short time frame because of the increased productivity of the power plant. Knowing the types of condensers assists you with having a better decision at the time of purchase. In the above article, we tried to look at the different kinds of condensers, their unique functions, pros, and cons.

Content Source: – linquip

Image Source: – mechanicaltutorial