Types of Pulley: Definition, Uses, Diagram, Examples, Advantages & Disadvantages

What is a Pulley?

Types of Pulley: Definition, Uses, Diagram, Examples, Advantages & Disadvantages :- Pulley is basically a wooden or metallic machine that uses a wheel and rope for lifting weight (loads) applications. Plastic pulley may be used to carry some lower loads. Pulley given an slight advantage in terms of that they can rotate freely about an axis to their center. Pulley can change the direction of force due to this load lifting application become a bit easier than expected. ( Examples of Pulley )

Or in other words pulley is a mechanical device which contains a wheel/ or chains & ropes or belts to lifting loads. Pulley is generally fixed to hinge.

Types of Pulley System

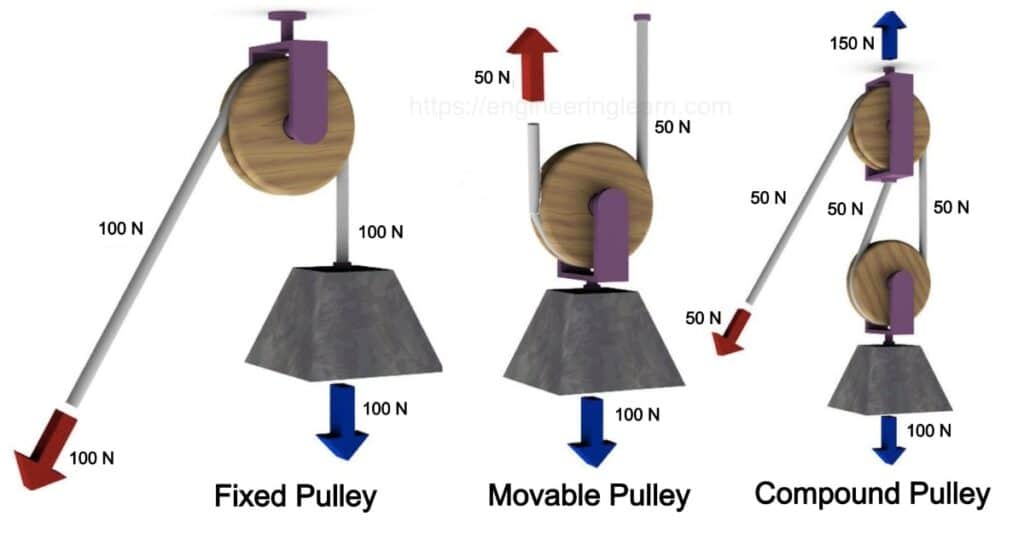

Generally there are 3 types of pulley system are following describe below:

- Fixed pulley

- Movable pulley

- Compound pulley

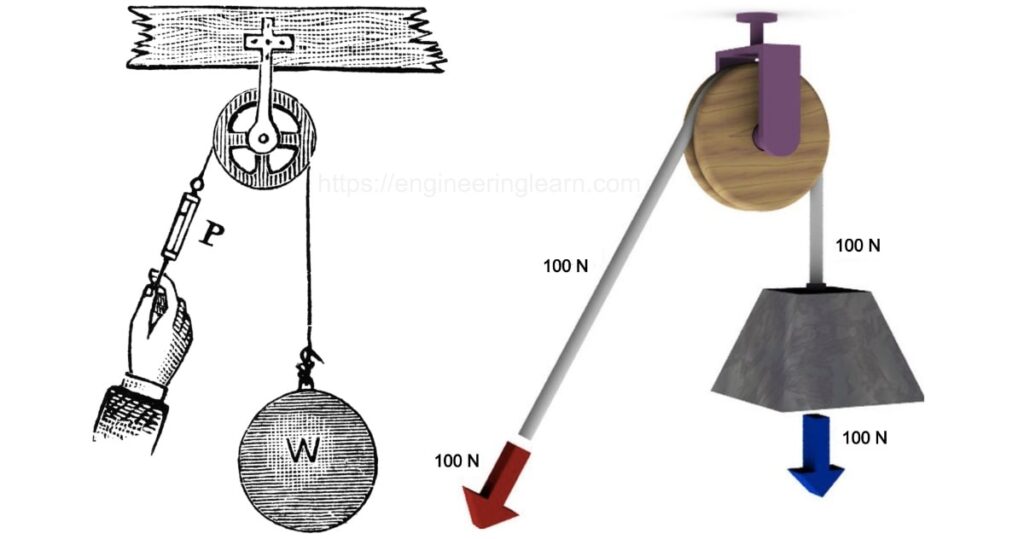

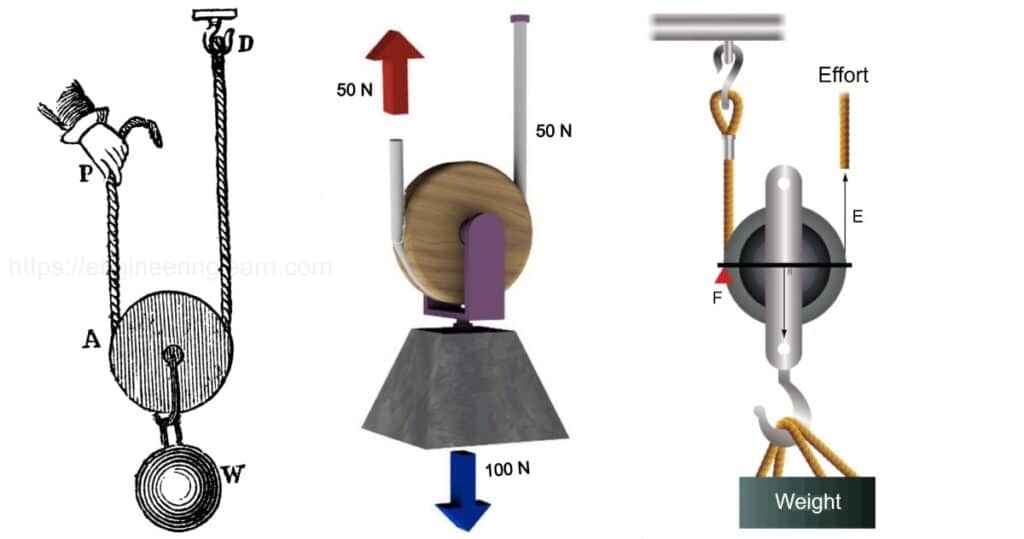

1. Fixed Pulley: ( Types of Pulley )

Fixed pulley system in which blocks of pulley is fixed onto a structural platform or fixed with this is known as fixed pulley system. An extensible string passes over the groove where it’s one end is attached to the object or body to be lifted while the other end is kept free. Wheel is fixed in such a way that it can rotate through the center.

2. Movable Pulley: ( Types of Pulley )

In this case of moveable pulley system block of the pulley is not fixed but it carries some load. This mode is known as moveable pulley system. An extensible string is tied around the groove where it’s one end is fixed to support thus other end is kept free to apply the effort, as the effort applied block together with load moves upwards.

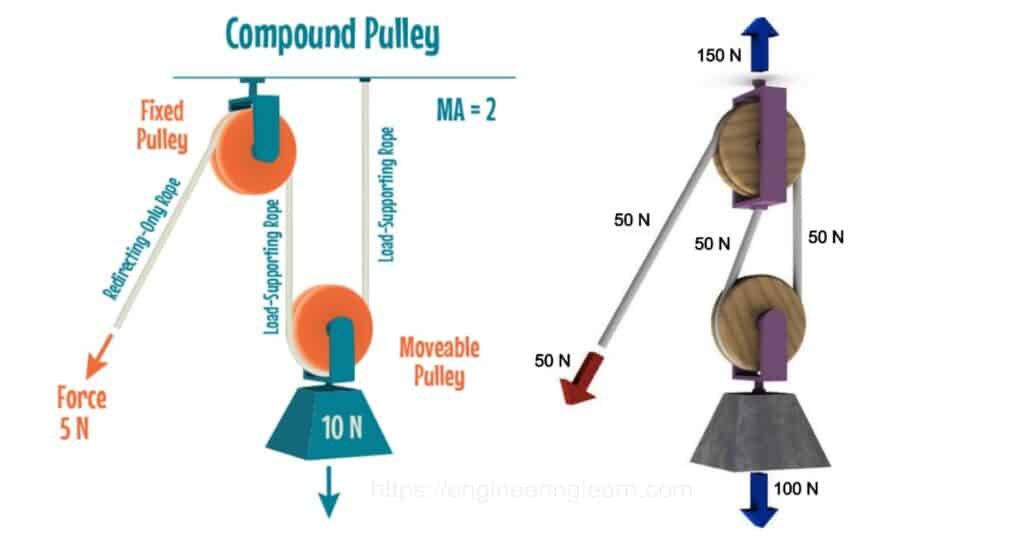

3. Compound Pulley: ( Types of Pulley )

In this class of pulley system several pulley are attached to some fixed pulley with the help of single or multiple ropes. As the number of wheel increases so lees amount of effort needed or applied to lift the heavy loads of body during operation.

Measurement (Performance of Pulley)

A term mechanical advantage is used to calculate the effectiveness of pulleys. Basically mechanical advantage is the ratio of utilised force to applied force to the work. Where some assumption to be made during calculation that are following:

- Weigh of pulley or ropes are negligible.

- There is no energy loss due to friction b/w the ropes and wheel grooves.

- It is also assumed that ropes/ belts used in operation doesn’t deforms.

Mechanical advantage of pulley system is directly proportional to the number of loops while the single loop means that amount of effort required to pull the weigh of is equal to weigh itself.

In double loop another loop is introduced so does the effort becomes 1/3 of the single loop arrangement. Pulley can be added to increase the mechanical advantage but there is certain limit after that mechanical advantage don’t change, becomes constant.

Advantages of Pulley

- Effort become less as compared to normal lifting.

- There is some distance b/w them to avoid any disaster.

- They are actually easy to assemble & cost effective.

Disadvantage of Pulley

- There are also several disadvantage in their use. Disadvantage of pulley system is that requires a large area to install & operate.

- They requires regular maintenance & check-up of ropes, chain or belts cause wear & tear to them.

- Continuous operation of pulley system that makes ropes quality degrade with respect to their strength also there will be slight fear for ropes of breakage during the operation period.