Types of Cooling System in Car Engine: Components & Function

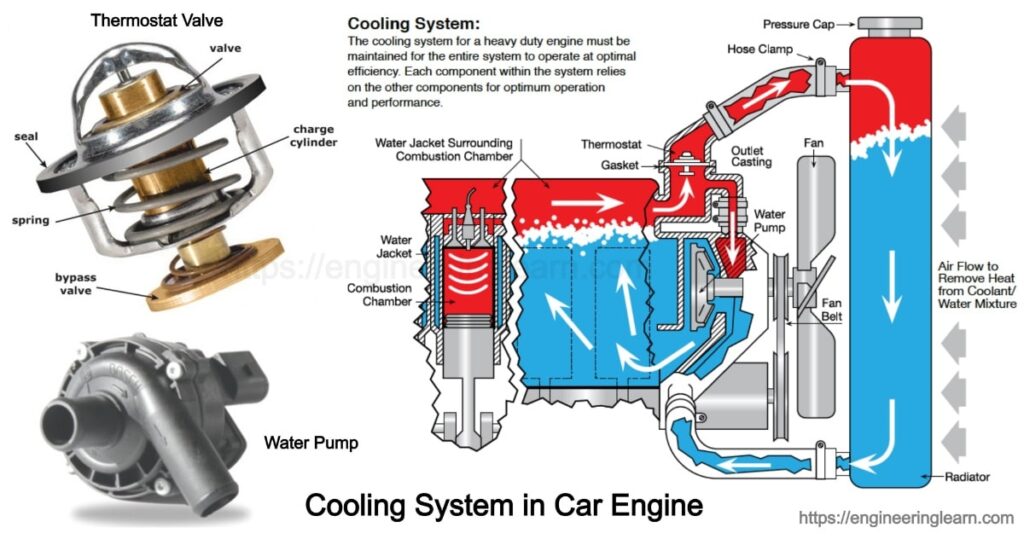

Types of Cooling System in Car Engine :- Components & Function :- A car engine cooling system not only keeps the engine of the vehicle cool but also stabilizes its temperature to fulfill the requirements for the working of the engine. The cooling system components have a radiator to dissolve the heat. Airflow for radiator cooling is ensured by a fan or fans.

The required operating temperature is reached with the help of a water pump (or coolant pump). The coolants flow into the engine, tubes, and other components. After that a thermostat valve is opened. Maximum vehicles now use an expansion tank that enables the coolant to- expand, exit (when the cooling circuit is heated) and reverse (when the car is turned off and the engine cools).

What is Cooling System?

A cooling system is basically a four cylinder vehicle that completes its journey producing 4000 explosions per minute inside the engine, when the spark plugs explode in each cylinder to move the vehicle. These explosions produce a great amount of heat that needs to be controlled. If they are not controlled they will destroy the vehicle. The controlling of these temperatures is primarily the job of the cooling system. The modern cooling systems are more efficient and reliable than those cooling systems of the 20’s.

How Does a Cooling System Work?

The coolant flows from the water pump, through the ways which are located inside the engine block. On its way it gathers the heat produced by the cylinders. After that it goes up to the cylinder head (or heads in a V type engine) where it collects the residual heat from the combustion chambers. Then the coolant makes its way to the thermostat in case the thermostat is opened to allow the fluid to pass. From there the coolant goes through the thin flattened tubes that make up the core of the radiator.

Inside there, the coolant is cooled by the air flow through the radiator. From here it flows out of the radiator by the lower radiator hose. It then goes back to the water pump. After this stage the temperature of the coolant is reduced and it can gather more heat from the engine. The capacity of a cooling system depends upon the engine. The cooling system for a bigger and powerful engine in a heavy vehicle will need high capacity than a compact car with a comparatively much smaller engine. In a bigger vehicle the radiator is bigger with numerous tubes for the coolant to flow through.

Types of Cooling System

There are two main types of a car engine cooling system:

● Air cooling system.

● Water cooling system.

1. Air Cooling System: ( Types of Cooling System )

They are found mostly in older cars and motorcycles, an air-cooled system where the engine block is covered in aluminum fins that conduct the heat away from the cylinder. A powerful fan forces air over these fins, which cools the engine by transferring the heat to the air.

The quantity of heat reduced by the air-cooling depends upon factors such as the total area of the fin surfaces, the velocity/amount of the cooling air and also the temperature of the fins and the temperature of the cooling air.

Air-cooling is mostly used in fewer horsepower engines like motorcycles, scooters, small cars, and small air car engines where the forward motion of the machine gives good velocity to cool the engine. Air-cooling is also offered in compact industrial engines.

Advantages of Air Cooling System

- They are cheaper to manufacture, need less care, and maintenance.

- The design of an air-cooled engine is simple.

- They are lighter in weight than liquid-cooled engines due to the absence of water jackets, radiators, circulating pumps, and the weight of the cooling water.

- This system of cooling is particularly advantageous where there are extreme climatic conditions in the arctic or where the evaporation factor of liquids is higher- deserts. Also, there is no risk of damage from frosts, such as cracking of cylinder jackets or radiator water tubes.

Disadvantages of Air Cooling System

- In comparison with others, they are less efficient.

- When these engines are used in cars, motorcycles or other vehicles. They are exposed to air directly.

2. Water Cooling System: ( Types of Cooling System )

In the water cooling systems, there are jackets that are provided along the cylinders, cylinder heads, valves, and seats. When the water circulates the jackets absorbs the heat of combustion. Then, the hot water will be cooling the radiator with the help of a fan for the moving of a car. The cooled water will again circulate through the jackets.

Advantages of Water Cooling System

- The constant cooling of cylinders, cylinder heads, and valves.

- The particular consumption of fuel through the engine.

- The engine is less noisy compared to the air cooling system.

Disadvantages of Water Cooling System

- It totally depends on the supply of water.

- The water pump during circulation absorbs a considerable amount of water.

- It is highly costly because of the number of parts. Thus, it requires more maintenance and care for the parts.

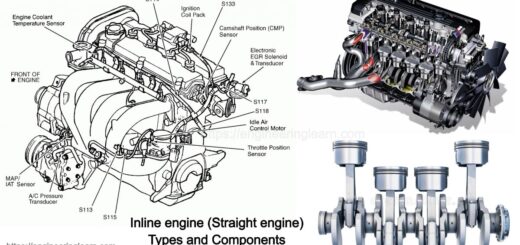

Components of Cooling System in Engine

The main parts of a cooling system are explained below

• Water Pump.

• Radiator.

• Thermostat.

• Coolant Temperature Sensor (CTS).

• Coolant (Antifreeze + Water).

• Radiator cooling fans.

• Heater core.

• Hoses

• Head gaskets and manifold gaskets.

• Freeze plugs.

1. Water Pump

The basic function of a water pump is to ensure the motion of the coolant when the engine is running. The water pump turns in the direction of the engine, wherever it is running. A part called fan belt is present whose function is to drive the water pump as well as the alternator.

2. Radiator

The core of the radiator core is composed of flattened aluminum tubes. There are also aluminum strips in zigzag shape sandwiched between the tubes. The function of these fins is to carry the heat in the tubes into the air stream. This heat is eventually transferred away from the vehicle. A plastic tank is located on either end of the radiator core. This tank covers the ends of the radiator.

The tubes are placed horizontal with the tanks on both the sides in the latest radiator designs. In the olden days the radiator core was made with copper and the tanks were made from brass. The cheap and easily manufactured aluminum– plastic system is very popular these days. It is more efficient too.

3. Thermostat

Thermostat is a device (valve) used to determine the temperature of the coolant. If the coolant is hot enough, the thermostat opens to allow the coolant to flow through the radiator. When the coolant is not of high temperature then the flow to the radiator is constrained. In such condition, there is a provision of a bypass system. The fluid goes to the bypass system and gets back to the engine.

This system is important as it maintains the constant and continuous flow of coolant throughout the engine. This continuous flow maintains the temperature and eradicates the formation of hot spots. When the flow to the radiator is choked, optimum operating temperature of the engine is achieved sooner. This will aid in a cold day by allowing the heater to start supplying high temperature air to the inside very fast.

4. Coolant Temperature Sensor (CTS)

The coolant temperature sensor functions to check the temperature of the engine. The ECU uses this information to regulate fuel injection and ignition time. There are many types of engines; some engines have numerous coolant temperature sensors while some have just one. The information is also used to control the radiator fan and update the driver console’s temperature gauge.

Most coolant temperature sensors are negative Temperature coefficient type, which means as the temperature increases, the resistance will decrease. The CTS can have a two-pin type or a three-pin type, depending on the make of the vehicle.

5. Coolant (Antifreeze Water)

The coolant in today’s vehicles is the mixture of ethylene glycol (Antifreeze) and water. The recommended ratio is fi y-fi y. In simple words, one part antifreeze and one part water. This is the minimum recommendation that is used in automobile engines. Less antifreeze and the boiling point must be too low. For temperatures less than 0 degrees- 75% antifreeze and 25% water is ideally required. Pure antifreeze should not be used as it will not be much efficient.

How Antifreeze mixture is made

Antifreeze should not be drained each summer; it can be let in for two or three years. The water expands when it freezes, and if the water in an engine freezes it can burst the block or radiator. Ethylene glycol is mixed with water to reduce its freezing point to desirable levels. The main advantage of using antifreeze is to save the cylinder blocks, pipes and radiators from unwanted cracks which is produced by ice.

When the temperatures falls below 0 degrees, then water turns into ice. This ice has more volume as compared to water and hence it expands. This expansion is the only reason for cracks and hence antifreeze is added to water so that the water does not freeze.

Basic instructions of using Antifreeze

A good antifreeze solution should have the following properties:

1) it should mix with water easily.

2) It should not easily evaporate.

3) It should not lead to settlement of unwanted material in cooling system.

4) It should be completely safe and secure for the car cooling system.

5) It should be cheap and easily available.

6) It should not corrode the system.

Generally it is very rare that single antifreeze satisfies all the requirements. Following antifreezes are used on a general basis-

1) Methyl, ethyl and isopropyl alcohols.

2) Mixture of alcohol and water

3) Ethylene Glycol

4) Mixture of water and Ethylene Glycol

5) Mixture of glycerin with water

6. Radiator Cooling Fan

There is one or more than one electric fan inside the radiator is present which are located at the rear side of the radiator on the side nearest to the engine. There is a casing on these fan for safety purpose and to regulate the air flow. The primary function of radiator cooling fan is to maintain the air flow passing through the radiator when the speed of the vehicle is reduced or the vehicle is stopped. Whenever the vehicle stops with the engine being on, these fan reduce the temperature of the engine.

7. Heater Core

Another function of the hot coolant is to provide heat to the inside of the vehicle whenever needed. This mechanism is composed of a heater core which is connected to the cooling system with two rubber hoses. One hose fetch the hot coolant from the water pump to the heater core. The second hose sends back the coolant to the top of the engine.

8. Hoses

Numerous rubber hoses are used to connect the different parts of the cooling system. The main hoses are known as the upper and lower radiator hoses respectively. The hoses are nearly 2 inches in diameter.

9. Head Gasket and Manifold Gasket

An IC engine is composed of an engine block and 1 or 2 cylinder heads. The surfaces where the block and head meet are made flat for a tightly closed fit. However completely watertighting is not possible in order to prevent the combustion gases from flowing out. For sealing the blocks to the heads, a head gasket is put into use.

10. Freeze Plugs

When an engine block is fabricated, special sand is molded to the shape of the coolant passages in the engine block. This sand figure is located inside a mold. Into this mold liquid (molten) iron or aluminum is poured to form the engine block. The sand is slacken after the casting is cooled. Then the casting is removed through the holes in the engine block. The coolant then flows through these holes. These holes are then plugged so that the coolant doesn’t drain out.

Image Source :- trucknews