4 Types of Fuel Injector – Working, Uses, Parts & Diagram [Complete Details]

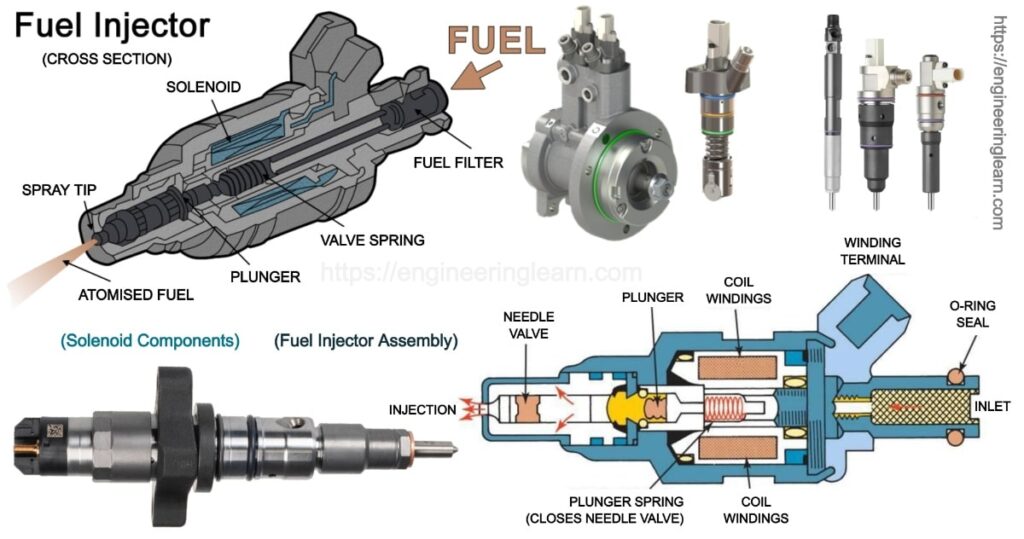

Types of Fuel Injector :- A fuel injector is a mechanical device which is controlled electronically and is mainly used to inject or spray fuel on the engine in order to prepare the correct mixture of air and fuel which returns in efficient combustion to the engine.

The position of the fuel injectors varies for differently designed engines but mostly these are mounted on the head of the engine with a tip inside the combustion chamber of the engine.

Types of Fuel Injectors

As soon as the fuel injection technologies got advanced, it gave rise to numerous fuel injection arrangements such as throttle body fuel injection, multi-point fuel injection, sequential fuel injection and direct injection which are used according to the required application whereas when it comes to the type of fuel injectors then it is really difficult to categories each of them. Moving further the fuel injectors can be categorized as –

A) On the Basis of Fuel

On the basis of fuel injected injectors, injectors are categorized as-

1. Diesel Fuel Injectors: ( Types of Fuel Injector )

The diesel fuel injectors are those which are used to spray the diesel directly into the combustion chamber of the diesel engine. The diesel is sprayed on the combustion chamber, and a high pumping is required for this as it is a heavier fuel as compared to gasoline which is responsible for further combustion by compression.

The capillary and nozzle of diesel fuel injectors are designed in such a way that they can form diesel packets which helps in spraying the fuel inside the combustion chamber of the engine.

2. Gasoline Fuel Injectors: ( Types of Fuel Injector )

The gasoline fuel injectors are those which are used to spray gasoline either directly or through a manifold intake into the combustion chamber of the engine which initiated the further combustion by spark.

Here, the high pumping of gasoline is not required as it is lighter than diesel.

B) On the Basis of Fuel Metering

On the basis of fuel metering, the fuel injectors are categorized as follows-

1. Mechanically Controlled Fuel Injectors

Mechanically controlled fuel injectors are those fuel injectors which are responsible for controlling the speed of the fuel, its quantity, timing and pressure which is done mechanically by using a spring and plunger and the input is taken by the arrangement of the cam and the fuel pump or the fuel distributor.

2. Electronically Controlled Fuel Injectors

Electronically Controlled Fuel Injectors are those in which the control of the fuel speed, its quantity, pressure and timing is done electronically and only with the help of the electronic solenoid which takes the input either from the fuel distributor or from the electronic control unit of the vehicle.

Fuel Injector Parts and Functions

If we discuss the constructional design of a fuel injector then it must be said that it resembles a lot with the nozzle of a garden shower which is commonly used to spray water over the ground grass. The purpose of a fuel injector is quite similar but the difference just that the injector sprays fuel inside the engine. Scroll down to know more about the construction of a mechanically controlled fuel injector and an electronically controlled fuel injector:-

A) Mechanically Controlled Fuel Injectors

Mechanically controlled fuel injectors are constructed using the following parts:-

Injector body: ( Function of Fuel Injectors )

The injector body is the outer cover of the body which can also be called as the shell of all the other parts of the injectors that are arranged just like a garden shower. The inner portion of the injector body is designed in such a manner that it can hold an accurately designed capillary or passage through which the highly pressurized fuel from the fuel pump can move ahead.

Springs: ( Function of Fuel Injectors )

Two springs are mainly used inside the mechanically controlled fuel injectors which are-

1. Plunger Spring

The plunger spring is responsible of controlling the to and for movement of the plunger which is responsible for controlling the fuel pressure inside the fuel injector which gets increased and thus results in the opening of the nozzle and then returns to its initial position, once the pressure decreases the nozzle gets closed.

2. Main Spring

The working of the main spring is to control the inlet of the fuel injector. The main spring works under the action of a fuel pressure which is usually provided by the fuel pump.

B) Electronically Controlled Fuel Injectors

Electronically Controlled Fuel Injector is a smart injector which is controlled by the electronic control unit of the engine and is also referred to as the brain of the modern engines.

Injector body: ( Function of Fuel Injectors )

Injector body is same as that of a mechanically controlled fuel injector, which is accurately designed shell inside which all the parts are arranged systematically.

Plunger: ( Function of Fuel Injectors )

A plunger is referred to as a device which is used for opening and closing the nozzle in an electronically controlled fuel injector with the help of an electromagnet.

Image Source :- Fahadhvhassan, Borgwarner, Slideplayer