Rotary Vane Pump: Definition, Types, Working, Components, Application, Advantages, Disadvantages (Sliding Vane Pump)

What is Vane Pump?

Rotary Vane Pump: Definition, Types, Working, Components, Application, Advantages, Disadvantages (Sliding Vane Pump) :- A vane pump is a commonly used device to increase the pressure of the flowing fluid using the vanes mounted to a rotor. It is a positive displacement pump device. It was invented by Charles C. Barnes in 1874.

Significance of Vane Pump

A vane pumps can be used to flow the fluid at high pressure from one point to another. Vane pumps are widely used in automobiles and are also used in air conditioners.

Vane pumps can flawlessly handle low viscous fluids like ammonia, solvents, alcohol, LPG, etc., and can handle moderately viscous fluids as well, but are not good for highly viscous fluids. A vane pump can also be used to converting high-pressure gas to low-pressure gas.

Working of Vane Pump

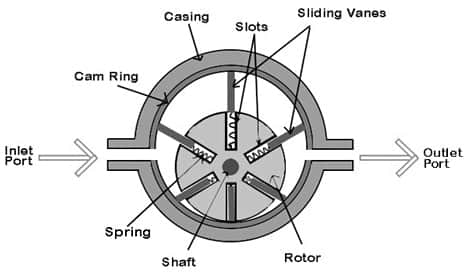

- Using an electric motor, power is provided to the shaft of the pump, after which the shaft starts rotating, which also rotates the rotor mounted on the shaft. As the rotor rotates the sliding vans present in the slot of the rotor experience a radially outward directed centrifugal force.

- The vans open due to the outward centrifugal forces on the sliding vane, which expands the spring that adjoins the rotor and vanes. The sliding vans establish contact with the cam-ring as the springs expand, and this contact remains established until the rotor rotates.

- The springs of the vanes are compressed to maintain contact with the cam ring as the vane reaches a position where the distance between the rotor shaft and the casing is short. When this happens, the area between two adjacent vanes and the casing also becomes smaller, i.e., the pocket-size gets smaller.

- Similarly, the spring of the vanes expands to maintain contact with the cam-ring when the vane reaches a position where the distances between the rotor shaft and the casing get larger. In such a case, the area between two adjacent vanes and the casing also gets larger.

- After a while of continuous rotation of the motor, suctions are formed in the inlet port, which causes the fluids to be sucked into the inlet port. This fluid, which is being sucked through the inlet gets trapped between two adjacent vanes.

- However, these vanes are always in contact with the cam-rings, the trapped fluid rotates along with the two side by side vanes. Due to the increasing distance between the shaft and the casing the space between the two adjacent vans near the inlet of the vane pumps increases.

- This results in a vacuum build-up near the inlet of the vane pump. Due to this vacuum suction starts, and fluid starts being drawn from the pump’s inlet.

- The fluid experiences a centrifugal force while moving from the inlet port to the outlet port, which increases the pressure of the fluid. This high-pressure fluid is pushed through the outlet port to the required location.

- As the rotor inside continues to rotate after that, the compression of the fluid continues to rotate, the space between the adjacent vanes starts decreasing, i.e., the pocket size starts decreasing.

- This results in the decrease of fluid volume and the entangled fluid gets narrower, and the fluid pressure starts to increase. As a result, high-pressure fluids are pushed from the outlet of the vane pump.

Components of Vane Pump

1. Shaft

The shaft inside the vane pump is connected to the prime mover. Using the power of this prime mover the rotor mounted on top of the shaft is rotated.

2. Rotor

The rotor of the vane pump has various radial slots which are present at equal distances all around the rotor of the vane pump.

3. Casing

The casing is the outside layer of the vane pump and consists of all the components of the vane pump that are present inside it. The casing consists of two ports:

- Inlet Port

This is the port through which the fluid enters the pump.

- Outlet Port

Through the outlet port, the high-pressure fluid exits the pump.

4. Cam Ring

The cam ring is mounted on the inner wall of the casing

5. Sliding Vanes

These rectangular-shaped sliding vanes are attached with the rotor using a spring and are present in the slots of the rotor and move freely inside the slots of the rotor.

Types of Vane Pump

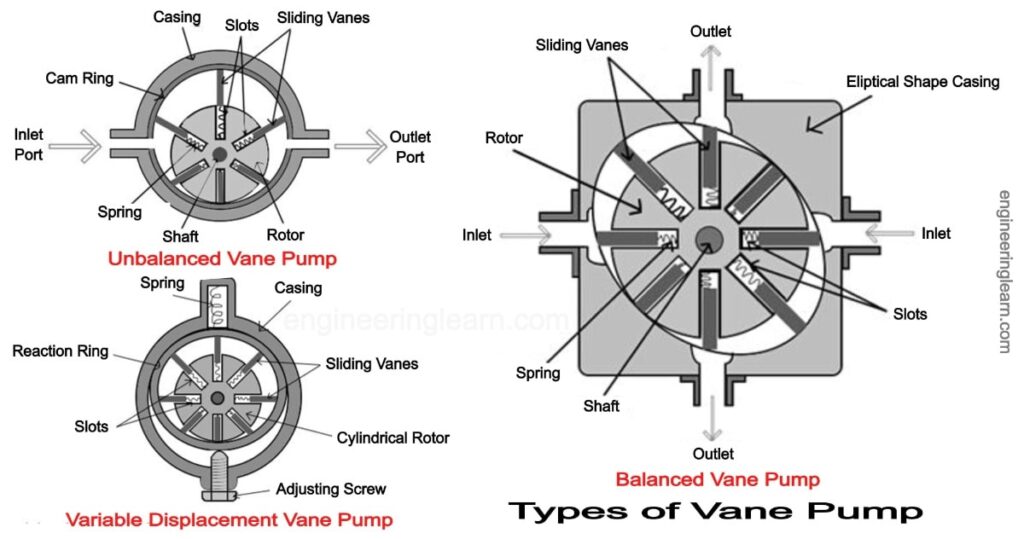

1. Balanced Vane Pump

2. Unbalanced Vane Pump

3. Variable Displacement Vane Pump

1. Balanced: ( Types of Rotary Vane Pump )

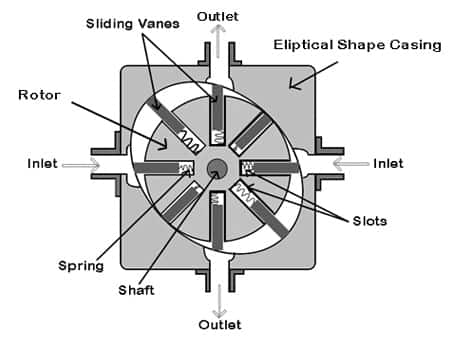

A balanced vane pump has an elliptical-shaped casing. The rotor and elliptical casing of this pump have the same centre. There is no offset is used. Two inlets and two outlets are provided for equilibrium, which helps in maintaining no pressure difference between the inlet and the outlet. Both inlets and outlets are present on opposite sides of each other. This arrangement of opposing each inlet and outlet helps in balancing equal and opposite thrust, and therefore no side thrust is experienced by the rotor shaft.

A balanced vane pump provides better service and longer life. While moving from the outlet to the inlet, the pocket size between the two vans increases, and while moving from the inlet to the outlet, the pocket-size decreases. This is why the inlet port has suction and the outlet port has delivery.

2. Unbalanced: ( Types of Rotary Vane Pump )

Unbalanced vane pumps are in general used vane pumps and are given their name due to the availability of different inlet and outlet ports. An unbalanced vane pump generally comprises of a cylindrical rotor fitted on an offset inside a round casing. The centre of the cylindrical rotor and the centre of the casing is not coincidental but are at some distance. Its sealings are so good that no leakage has been observed between the vane tips and the casings. Due to the pressure differential between the inlet and outlet port, a side thrust is also noticed on the rotor shaft. This reduces the bearing life.

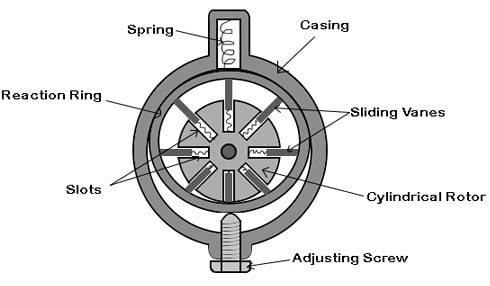

3. Variable Displacement: ( Types of Rotary Vane Pump )

The pocket size in a variables displacement vane pump can be varied according to requirements. This results in variations in discharge from outlets. The casing in the variable displacement vane pump is not directly in contact with the rotor.

A reaction ring is provided between the casing and the pane. On one side, the feedback ring is connected with a spring, and on the other side, it is connected with the adjustment screw. The pocket-size of the pump can be adjusted using the adjustment screw. Turning the adjustment screw results in the upward and downward motion of the reaction ring by which the offset between the reaction ring centre and rotor centre can be changed. Changing the offset results in changes in pocket size, which in turn varies the discharge from the pump.

Working Principle of Vane Pump

- A vane pump generates pumping action by tracking the vanes along the casing wall. These vanes are located on the slotted rotor and the rotor inside the pump is connected to the prime mover through a shaft.

- The rotor inside the vane pump is placed eccentrically inside a cam ring and is sealed by two side plates, into the cam. As the prime mover rotates the rotor, due to centrifugal force, the vanes are pushed outward.

- These vanes provide intact hydraulic sealings to the fluid by tracking along the ring, which is more at the higher rotational speed due to high centrifugal force. This in turn produces a suction cavity in the ring.

- A vacuum is created at the inlet by the rotation of the rotor which therefore pushes the fluid to the pump through the inlet. The vanes carry the fluid around the outlet, by which the fluid is ejected by retreating.

- The efficiencies of the vane pump mainly rely on the expansion and the width of the vanes, rotor speed, and eccentricity. It should be noted that if the eccentricity of the rotor is zero, the fluid will not flow.

Application of Vane Pump

A vane pump has various applications for the pumping of the following fluids

- Aerosol and Propellant

- Aviation Services – Fuel Transfer, De-icing

- Fuel, Lube, Refrigeration system for automobile industry

- Bulk transfer of LPG and NH3

- LPG cylinder filling

- Alcohol

- Refrigeration – Freon, Ammonia

- Solvent

Advantages of Vane Pump

- Vane pumps are useful where a continuous delivery at a fixed speed is required.

- They gives uniform discharge with almost zero vibrations.

- Their vanes are self-compensating for wear and tear and the vanes are easily replaceable.

- A check valve is not required in vane pumps.

- They are light-weight and compact.

- Liquids containing vapours & gases can be easily handed..

- They have high volumetric and overall efficiencies.

- Low viscosity fluids can be easily handled at high pressures by vane pumps.

- It can also dry run for short periods.

- This pump develops a good amount of vacuum.

- Higher operating pressures can be used since balanced pump bearing eliminates side loads

Disadvantages of Vane Pump

- In the event of a sudden stop of delivery, relief valves are required to protect the pumps.

- Vane pumps are not suitable for abrasive liquids.

- A good amount of sealing is required.

- A proper filtration system is required since foreign particles can cause serious damage.

- Vane pumps have complex design.

- High viscosity fluids at high pressures cannot be handled by these pumps.

- They are fixed displacement pumps.

- As compared to unbalanced type, their manufacturing cost is significantly higher.

Image Source :- mechanicalwalkins