Pinch Valve: Types, Function, Components, Working Principle, Applications, Advantages & Limitations

What is a Pinch Valve?

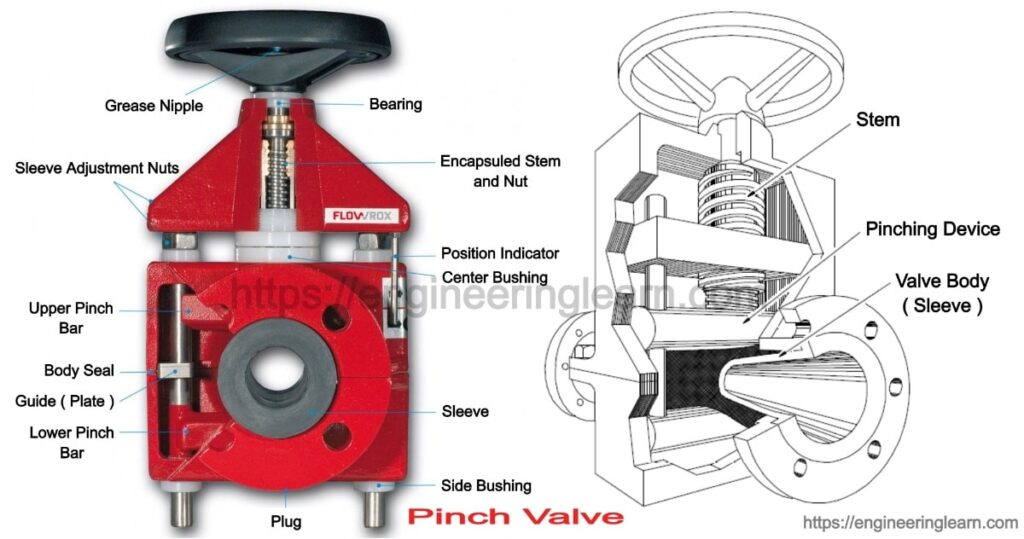

Pinch Valve: Types, Function, Components, Working Principle, Applications, Advantages & Limitations :- The pinch valve or sometimes called squeeze valve is a flow control valve which operates on the squeezing action of rubber sleeve inside the valve. The valve is opened or closed by compressed air, which squeezes the rubber sleeve and controls the passage area. The valve has no constraints in the open position, allowing a wide range of media to pass through the bore. The valve’s flexible interior rubber sleeve isolates the medium, reducing the danger of contamination.

Significance of Pinch Valves

Pinch valves are ideal for segregating and controlling abrasive, corrosive, and fibrous materials. For emulsions, sludges, dusts, gaseous materials, compressed air, powder, granulates, and pellets, the pinch valve is extensively being applied as an isolating or regulating valve. These valves are inexpensive, durable, and simple to operate, making them ideal for a variety of industrial applications.

Pinch Valve Components and Working Principle

A pinch valve is made up of three main parts: housing, an internal rubber sleeve and end connections. The rubber sleeve is the only component that comes into contact with the media and is inserted into the housing from input to output. To give support and connection to the valve, the end connectors are fastened, screwed, or threaded at both of the end. When compressed air is delivered to the valve, it pushes the rubber sleeve down. The flow is stopped and the valve is closed when the rubber sleeve is entirely pinched. Unlike traditional valves such as ball Valve or gate valve, which can trap particles around the ball or discs, the rubber sleeve of a pinch valve can capture particles around it, resulting in an excellent shut off.

The elastic rebounding property of the rubber sleeve, combined with the force of the flowing media, fully opens the valve when the external air pressure is no longer applicable. The flowing media is only in contact with the rubber sleeve, which consequently isolates the media, prevents contamination, and prevents damage to other parts. The rubber sleeve absorbs the impact of the flowing media and deflects it back when it strikes it. This robust feature allows the rubber sleeve to wear at a somewhat slower pace than metal surfaces, resulting in a longer service life.

Types of Pinch Valves

The pinch valves are generally of three types; normally open (NO) pinch valve, Normally close (NC) pinch valve and Changeover (CO) pinch valve. However, NO type pinch valves are used commonly to incorporate the flow control but according to the use and fluid control the different pinch valves are introduced in the system.

1. Normally Open (NO) Pinch Valve

These valves are in open condition at the non-pressurized state (normal state). To close the valve the pressurized air is inserted over the rubber sleeve to induce the pinching effect. These valves actuates on two kind of pressure forces; operating pressure (fluid pressure) force and positive control pressure (air pressure) force.

2. Normally Closed (NC) Pinch Valve

These valves are generally closed at the non pressurized state. The closing operation is performed by the spring element which forces the pinch element to be closed at normal conditions. As the negative pressure (vacuum pressure) is applied at the air vent of the valve and exceeds the spring force, the rubber sleeve opens the passage and the flow starts. The actuation of the sleeve is done by the spring force, operating pressure force and control pressure force.

3. Changeover (CO) Pinch Valve

The CO type valve incorporates dual channel operation, which means its half part is made No type and another half is made NC type. The changeover between the NO and NC type can be done anytime by sliding the changeover nut. The actuating forces include in the operation of this valve is spring force, operating pressure force and control pressure force.

However, for different application, types of sleeves are also varied with the variation of input and output operating fluid pressure. In general, full port sleeve and double wall port sleeve are used but there are other types of sleeves which are used for different purposes such as cone sleeve, reduced port sleeve, variable orifice sleeve etc.

Criterion for the Selection of Pinch Valves

The selection of a pinch valve can be made on the basis of three main criteria: –

1. Material

The valve body material should have to be light in weight for easy handling and maintenance, but it is not required to be compatible with the flowing media because anyhow they will not come into contact with the body. However, because the rubber sleeve is the only component that comes into touch with the media, it should be given particular importance. Natural rubber, NBR (nitrile butadiene rubber), EPDM (ethylene propylene diene monomer), silicon, food-grade rubber, and other materials may be used as the rubber sleeve. To avoid damage from the media, the material should be abrasion resistant.

2. Pressure

The pressure of air is the main element for the selection of the pinch valve. The pressure of air applied to create the pinch effect is known as control pressure and the pressure of flowing media is known as operating pressure. For opening the valve, it is necessary for the operating pressure to be higher than the control pressure, although, the control pressure is usually 0 bar. The operating pressure will not be able to open the sleeve if the pressure differential is less than the control pressure. For closing purpose, the control pressure must be higher than the operating pressure. The control pressure will not be able to overcome the operating pressure while pushing the sleeve to close the valve if the pressure differential is insufficient. The A is the operating pressure of the flowing media whereas B is the control pressure of the air.

3. Temperature

The valve material, especially, rubber sleeve should have to sustain the temperature of the flowing media. Otherwise, the unsuitable temperature may damage the rubber sleeve and leakage occurs.

Applications of Pinch Valve

The advantages of the pinch valve are so approving that the limitation merely affect application of the pinch valves in different industries. The main industries which utilize the pinch valves are – food and beverage industries, pharmaceutical industry, chemical industry, cement industry, bulk and solid handling industry, ceramic industry, plastic industry, wastewater industry etc.

Advantages of Pinch Valve

The advantages of pinch valves are shown below;

- Highly suitable for abrasive or corrosive media.

- The flow path is straight and there is no amalgamation or clogging in the flowing media particles.

- Less friction and turbulence inside the valve.

- Ensures the media free from any contamination.

- Easy and cheaper to maintenance.

- Exceptional sealing capabilities.

- Quick in operation.

Limitations of Pinch Valve

Along with the advantages there are some limitations that may affect the characteristics of pinch valve.

- The valve is not suitable for high temperature applications due to the elastomeric feature of the sleeve.

- Because of the high pressure differential, the rubber sleeve can collapse or distort, causing the valve to not fully open.

- The valve is not advised to use for vacuum applications because the sleeve may collapse due to suction.

Image Source :- Valvedistributors, Forumautomation