What is Differential? Types of Differentials, Function & How They Work [with Pictures]

![What is Differential? Types of Differentials, Function & How They Work [with Pictures]](https://engineeringlearn.com/wp-content/uploads/2021/08/Differential-1024x539.jpg)

What is Differential?

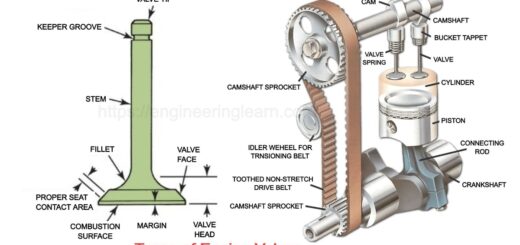

What is Differential? Types of Differentials, Function & How They Work :- A differential system can be regarded as a system whose primary function is to transmit an engine’s torque to the wheels. The differential works with the help of the power it takes from the engine and then splits it, which in turn gives the wheels the freedom to turn in different speeds. When on a turn, the outside wheel is observed to travel farther and faster than the wheel which is inside. The differential thus plays an important role as it is a set of gears that is behind the transmission of engine power to the wheels, hence leveraging them to turn at varying speeds approaching a turn.

When considering front-wheel-drive (FWD), the differential placement is such that it is in same direction as of the transmission present inside the housing, and this whole unit is widely regarded as a transaxle. Whereas incase of rear-wheel-drive (RWD), the differential is situated in between the pair of rear wheels, in direct connection with the transmission with the help of a driveshaft. In the case of All-wheel-drive (AWD) and four-wheel-drive (4WD) vehicles, there is an additional setup of Centre differential or transfer case which helps in distribution of power in front and rear.

Types of Differentials

Differential are categorized to be of following main types:

- Open differential

- Locked differential

- Limited slip differential

- Welded differential

- Active differential

- Torsen differential

- Torque Vectoring differential

1. Open Differential: ( Types of Differentials )

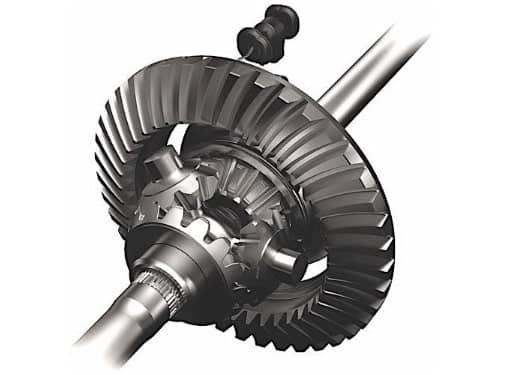

Open differential is referred to as one of the most basic form of differential which is found being comprised of two halves of an axle accompanied with a gear on both its ends. These are found to be connected together using a third gear which is responsible for making up three sides of a square. These differentials are further used along with a fourth gear for more strength. This is what results in completion of the square.

This complete unit system then further gets an addition of a ring gear to the differential case, the main function of which is to hold the basic core gears in correct position and this ring gear arrangement thus results in the wheels which are to be driven by the drive shaft using the pinion. These are referred to as a type of gearing arrangement which is found in open differential system and is thus considered as the most common type of automotive differential system. This is responsible to form the base for various diverse and complicated set of systems.

The advantage of such type of unit is found to be quite similar to any other differential which is described previously. Keeping a focus on aiding the axle to corner more efficiently by allowing the wheel on the outer side of the turn in order to run it at a speed which is observed to be faster as compared to the inside wheel as it has to cover more ground. One additional benefit of this unit system is that it is found to be comparatively cheaper to the manufacture.

At the same time the system has certain demerits which is that because of an even split of torque within both the wheels, the quantity of power which can be carried forward by the help of the wheels is found to be limited only to the wheel which has the lowest amount of grip on offer.

2. Locked Differential: ( Types of Differentials )

The locked or locking differential is referred to as a type of differential system which is found to be more popular on those vehicles that go off road more frequently primarily. These differentials are considered as an open differential but along with an additional advantage of having it locked in place, if need be, to make it function as a fixed axle rather than an independent one. This is found being happening to either manually or even electronically subject to the technology on the vehicle.

The main advantage of a locked differential is found to be that it is highly prone to develop in order to gain a considerably higher amount of traction which is compared simultaneously with an open differential. As the distribution of the torque in this type of system is not found to be equally 50/50, which can possibly transfer more torque to the wheel that experiences a slight better traction out of the two which are available which is not handicapped by the lower traction that is present on the other wheel at any given point of time.

As it is highly rare for the user who is found travelling at a greater velocity wherein the user is usually found travelling over those surfaces which are found to be rough as well as uneven. There are various problems like wear around the corners on a fixed axle wherein the tyre is found being dragged and thus are less of an issue.

There is one demerit of the locked diffs which is usually found in the form of binding that appears quite often whenever the system is found facing higher build-up of torque (rotational energy) within the drive train that needs an immediate release for better functioning. This is mostly found by the wheels which pretend to be leaving the ground for resetting themselves for their initial position which can release the locks once they are no longer required.

3. Limited Slip Differential: ( Types of Differentials )

LSD’s is found working in such a way that they are found to add up the advantages of both open as well as locked differentials through a system which is to be simply put, rather cannot be that complicated. There are mainly two types of categories which are responsible for utilizing various different forms of resistance in order to get the desired effect:

A) Mechanical Clutch LSD

These are referred to as the type of LSD functions which work on the same principle of core gearing that is found being seen in the open diff which usually comes accompanied with a pair of pressure rings. The main function of this LSD is to exert the force on both sets of the clutch plates which is found to be positioned in a way that is parallel to the gears. Mechanical Clutch LSDs are the ones which are found to be split further into subtypes that function in a bit different way and is subjected to change when there is observed a pressure change on the clutch plates:

- Considering the case of a one-way LSD, the pressure is found to be exerted only at that particular moment when it is found undergoing acceleration. This leads to a conclusion that while performing any operation of cornering and getting off the power, the diff functions as an open type differential, which is responsible for allowing those wheels to independently turn – whereas whenever the force of acceleration is being experienced, the forced rotation of the differential results in friction amongst the clutch plates which leads to locking them in their place in order to gather more traction.

- A Two-way LSD is a method which seems to be similar to a one-way LSD and it goes one up and characteristically exerts more pressure on the clutch plates even when they are undergoing deceleration. The main aim of this LSD is to improve the stability under the situation of braking on variable surfaces of road.

B) Viscous LSD

Viscous LSD’s being the second type of limited slip differential, there is found to be a significant amount of usage of a thick liquid in place where the clutches are responsible for creating the resistance which is actually required with an aim to alter the behavior of the differentials within the state of open and locked. Because of containing a much fewer moving parts which are simultaneously compared to a mechanical LSD, VLSD’s are thus considered to be a simpler one which is also said having possessed a wider range of merits as well as demerits which are in comparison.

VLSDs are referred to as the ones which are successful in directing torque more efficiently and effectively so that the wheel pretends to possess more traction. As the fluid is found having a tendency to act being resistant under the speed, in case a wheel experiences any loss of traction and spins, the difference in speed amongst the two wheels which is present inside the differential is responsible for creating more resistance on the wheel which moves slowly– channeling the greater amount of torque from the drive shaft to it.

4. Welded Differential: ( Types of Differentials )

Welded differentials more or less functions like a locked differential, only point of difference being that it is subjected to permanent welding from a differential (open) into a fixed axle. This is done only in certain specific situations where the characteristics of the fixed axle, which makes it less complex to keep both wheels simultaneously spinning, are necessary – for example, in cars which are meant for the purpose of drifting.

A welded differential’s purpose is to keep both of the wheels on the back of on the car spinning at same/identical speed, but since the wheel present on the outside is spinning comparatively faster than the one which is present on the inner side in a turn, maintaining the same speed on both wheels will cause the inner wheel to lose traction and ultimately slip, making oversteer quite prevalent. But welding a differential is a thing which is very permanent and cannot be changed later, and it will have side effects as well.

It’s in most cases not recommended as the heat from welding can lead to a heavy toll on component strength and give rise to a catastrophic part failure – potentially leading to dangerous cases of explosion of the broken differential gears through the differential casing and becoming a threat to safety of other pedestrians and road users.

5. Active Differential: ( Types of Differentials )

Being more or less similar to a limited slip differential, the active differential ends to work on certain mechanisms so as to provide the system with the required resistance for the further transfer of torque from side to side, but instead of relying on forces which are purely mechanical, these clutches can also be activated electronically.

This active differential is highly capable of making the use of electronics to artificially change the mechanical forces the system is undergoing by changing the conditions of driving. This makes them programmable and henceforth controllable, and with the help of a range of sensors present across the vehicle, a computer can on itself detect which drive wheels and when it requires power.

This improves performance drastically, especially overroad surfaces which are not good, and is particularly used in rally cars which have to endure rapidly changing conditions of driving and require a system that can maintain itself with continuous adjustments the vehicle undergoes.

6. Torsen Differential: ( Types of Differentials )

The Torsen (Torque – Sensing) differential makes the use of some particularly clever gearing to function properly and reciprocate the similar effect which is found in a limited Slip Differential without in return making any sort of use of clutches or fluid resistance.

It successfully attains this by addition of a worm gearing layer to an open differential’s traditional set up of gear. These sets of worm gears which are acting on both of the axle provide the required resistance to open up the torque transfer, which then is successfully achieved by the worm gears in mesh (constant) with each other with the help of spur gears which are connected.

Also, an open differential characteristically always has a tendency to split its torque 50/50 between each of its wheel, due to its high capability of directing a considerable higher percentage of torque through one wheel varying on the ratios of the gears, torsion differential is very useful.

7. Torque Vectoring Differential: ( Types of Differentials )

The Torque Vectoring Differential is considered to be an even more advanced electronically enhanced system which can further even alter and manipulate the angle/dynamics/vector of the vehicle in and out of the turns by permitting only certain specific wheels to achieve more torque at key moments –thus leading to an improved cornering performance.

When approaching a corner, what a multi-way Limited Slip Differential does is that it applies resistance on both the wheels so that it locks the axle partially and stabilizes it while the operation of braking – which soon after that is released as the speed of the wheel slowly drops and the vehicle turns in, permitting the wheels to rotate at different velocities.

However, rather than releasing the resistance on both the wheels, what a TVD does is that it continues to apply the clutch on the wheel present outside– thus increasing the resistance being faced by that particular wheel and making the channel transfer more torque through the same. This resultant power imbalance is the reason behind the vehicle sharp turning into the corner and in return reducing the phenomenon of understeer.

While the TVD continues exerting more resistance onto the clutch of outside wheels, it certainly imposes the system through it to divert more torque– thus increasing the amount of applied power and reducing the understeer which is experienced when accelerating out of a corner.