Nut & Bolt | What are Nuts? | What are Bolts? | Difference Between Nuts and Bolts [Complete Guide]

![Nut & Bolt | What are Nuts? | What are Bolts? | Difference Between Nuts and Bolts [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2023/02/Nut-Bolt-1024x539.jpg)

Introduction of Nut & Bolt

Nut & Bolt | What are Nuts? | What are Bolts? | Difference Between Nuts and Bolts [Complete Guide]: – Nuts and Bolts go together and without the two of them, you can’t produce strong equipment. They are designed to work so that they strengthen anything that they are kept intact. The nuts are the ones with the threaded openings and they are coordinated with bolts that are basically designed to fit explicit nuts. Electrical equipment, automobiles, and spare parts are only a portion of the things that utilization of nuts and bolts for fasteners.

Nuts and bolts are dimension specific and are strong and durable to ensure the long life span of the product that they hold together. Different projects require various nuts and bolts. Strength ratings will let you know what kind of nuts and bolts you will need.

What are Nuts?

A nut is a little or small metal object with an opening in the middle that has a corrugated opening. These curved holes are known as threads. Nuts are utilized as a fastening device. It is vital to take note that nuts are utilized as a fastening device, they can’t be utilized without bolts. The external part of its body can be shaped one way or the other, yet it is generally hexagonal cap or circular in shape.

The inside shape is generally round; this is on the grounds that this is where the bolt stem fits, and the bolt stem is always cylindrically shaped in shape so it can rotate effectively and fit into the threads. The nuts accompany a different locking system that forestalls machine parts from loosening because of the vibration of the parts or parts that they joined.

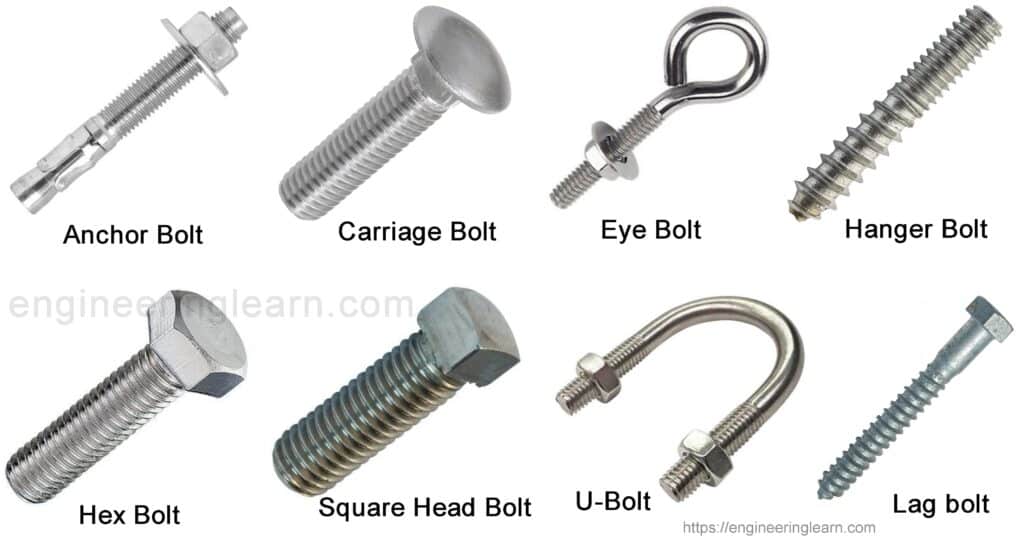

The nut has internal threads with the goal that it can be tightened effectively on the bolt. The size of the nut is more modest than that of the bolt. The nuts experience compression forces. Compressive pressure prompts its failures. There are various sorts of nuts: Hex Nut, Nylon Supplement Lock Nut, Jam Nut, Nylon Addition Jam Lock Nut, Square Nut, Cap Nut, Oak seed Nut, T-Nut, Cape Nut, Palace Nut, Wingnut, Spine Nut, Opened Nut, Coupling nut, and so forth.

The fundamental reason for this is that it provides more noteworthy granularity, to be specific the grip of the device that can be utilized to remove the nut. Besides, assuming there are an excessive number of sides, it implies more wear and tear, and in this manner, the six sides provide the ideal solution for both of these problems. There are various kinds of nuts, contingent upon the reason for which they are utilized.

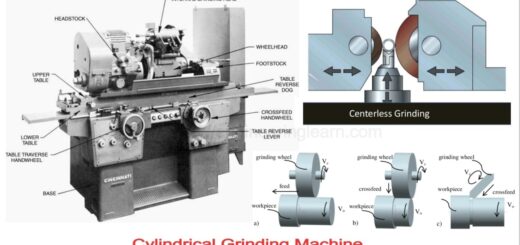

What are Bolts?

Bolts are metal objects comprising a cylindrical trunk with grooves, for example, grooves that are like the grooves present inside a nut. Notwithstanding this threaded stem, there is likewise a forward current, which helps hold the fasten together. A bolt goes into a hole in a circular thread of a nut, where the bolt grooves fit without any flaws with the nut grooves.

A few bolts have this threaded nature with their trunk; some have just the last part of their stem. There is no reasonable differentiation between bolts and nuts, and one can undoubtedly get confused between them, yet typically, the bolts don’t go through a threaded area and are fastened with the assistance of bolts; in any case, utilized for components that have proactively been damaged.

A bolt head likewise has a wide variety of shapes, and we really want to follow similar guidelines. The most well-known shape for a bolt head is a hexagonal bolt head since this shape gives the most granularity to the devices utilized on account of extraction.

A bolt is threaded externally. It tends to be completely loaded, to some partially threaded. The bolts are cylindrical in shape. The solid cylindrical part is known as the shank. The bolt is larger in size as compared to the nut. Bolts experience tensile forces. The tensile stress prompts its failure.

Different sorts of bolts anchor bolts, carriage bolts, lift bolts, spine bolts, holder bolts, hexagon bolts/tap bolts, slack bolts, machine bolts, furrow bolts, sex bolts, shoulder bolts, square head bolts, stud bolt, woods.

Where are Nut and Bolt Used?

Nuts and bolts are utilized in a wide variety of applications, including construction, Automotive, Machinery, and numerous different ventures. They are utilized to fasten and keep intact a large number of parts, like wood, metal, plastic, and many more.

A. Construction

In Construction, Nuts and bolts are utilized to keep intact structural components like pillars, joists, and framing. They are additionally used to attach hardware like hinges, handles, and locks to doors, windows, and cupboards.

B. Machinery

In machinery, nuts, and bolts are utilized to keep intact cogwheels, bearings, and different components. They are likewise used to attach motors, pumps, and other mechanical parts to machinery.

C. Automobile

In the automotive industry, nuts and bolts are utilized to hold together engines, transmissions, and different parts. They are likewise used to attach wheels, brakes, and different parts to vehicles.

D. Electronic Appliances

In electronics and appliances, nuts and bolts are utilized to hold together circuit boards, electronic parts, and different parts. They are additionally used to attach covers, panels, and different parts to electronic gadgets and appliances.

Generally speaking, stray pieces are utilized in many applications where parts should be held together safely. They are versatile and cost-effective fasteners that can be utilized in a wide range of sorts of materials and environments.

3 Key Factors to keep in Mind While Buying Nuts and Bolts?

1. Choosing the Right Nut and Bolt Type

There are a lot of options accessible in the market when you start searching for nut and bolt types, making the selection challenging and confusing. Likewise, some nuts and bolts that offer high strength when utilized in specific materials may not provide similar solidarity for different materials.

2. Choosing the Right Material

Recall that a nut and bolt are made of stronger material and may not really be the right pick for a wide range of applications. For instance, hardened steel nuts and bolts that offer increased strength are not appropriate in salt water and chlorine environments. All things considered, stainless steel with high resistance grades and anti-corrosive properties are preferred for such applications. In this way, make a point to purchase the actually needed material for your project or work.

3. Choosing the Correct Nut and Bolt Size

Knowing both the length and the breadth of any nut and bolt is a significant prior flat surface of the head to the tip or end of the screw. The diameter is measured from the external thread on one side to the outer thread on the opposite side. Choosing the wrong nut and bolt size can bring about misuse of the materials, and wastage of time and effort in completing a project or work. Along these lines, try to have precise measurements prior to purchasing them.

Difference Between Nuts and Bolts

Bolts and nuts are the two types of fasteners that are utilized to keep at least two parts together. In any case, they have a few key differences that make them more suitable for various applications.

#1. Use: ( Nut & Bolt )

Another significant difference is how they are utilized. A bolt is normally inserted into a hole in one of the parts to be joined, with the threads of the bolt facing out. The nut is then screwed onto the threads of the bolt to keep the parts intact. Then again, a screw is typically inserted into a pre-drilled hole in one of the parts to be joined, with the threads of the screw facing into the hole. The screw is then turned to thread into the opening and brace the parts together.

#2. Shape: ( Nut & Bolt )

One of the obvious contrasts between bolts and nuts is their shape. A bolt typically has a head toward one side and threads on the opposite end, while a nut is a cylindrical or hexagonal-shaped fastener with threads on the inside that match the threads of a bolt. The head of the bolt is utilized to apply torque to tighten or loosen the fastener, while the nut is utilized to keep the parts intact and prevent the bolt from turning.

#3. Material: ( Nut & Bolt )

The choice of material used to make the bolt and nut likewise play a part in deciding the strength and the suitability of the fastener for a specific application. Bolts and nuts can be made using a wide variety of materials, including steel, metal, titanium, aluminum, and many more. Each material has its own unique and remarkable properties, like strength, corrosion resistance, and cost, that make it more or less appropriate for various applications.

#4. Strength: ( Nut & Bolt )

With regards to strength, bolts are by and large considered as more stronger than screws. This is on the grounds that a bolt is designed to endure shear and tension forces, while a hole is designed to endure tension forces. A bolt has a smooth shank and the threads are on the finish line of the shank so that when the nut is tightened the clamping force is disseminated over the entire clamp, this offers a more prominent clamping force per square inch of the shank. Then again, a bolt’s strings run the whole length of the fastener, so when it is tightened it can clamp down on the material directly contiguous to the threads, this offers less clamping force per square inch of the shank.

#5. Durability: ( Nut & Bolt )

As far as durability is concerned, bolts are for the most part viewed as more durable than nuts. Nuts are designed to endure heavy loads and are most of the time utilized in applications where a lot of force is applied to the fastener. Screws, then again, are commonly utilized in applications where a smaller amount of force is applied to the fastener. Therefore, screws are bound to strip or break under heavy loads.

#6. Grip: ( Nut & Bolt )

One more significant difference between bolts and nuts is how they are tightened and loosened. To tighten a bolt, a tool or device, for example, a wrench or a socket is utilized to apply torque to the head of the bolt. To loosen a bolt, the tool is utilized the other way to apply force in opposite direction. Then again, to tighten a nut, a tool, for example, a screwdriver or a drill is utilized to turn the nut clockwise. To loosen a nut, the tool is utilized the other way to turn the screw counterclockwise.

#7. Extraction: ( Nut & Bolt )

One more significant difference between bolts and nuts is how they are removed. Bolts are normally removed by loosening the nut on the opposite end of the bolt. The nut can be removed by utilizing a wrench or a socket, contingent on the type of nut. Then again, screws are typically removed by turning them counterclockwise utilizing a screwdriver or a drill.

Conclusion of Nut & Bolt

Nuts and bolts are the basic components utilized in different sorts of machinery. To fit together, both the nut and bolts ought to be of a similar size. Bolts and nuts are the two kinds of fasteners that are utilized to hold at least two parts together. Bolts have a head toward one side and threads on the other, while a nut is a cylindrical and hollow or hexagonal-shaped fastener with threads within that match the threads of a bolt.

Bolts are more stronger than screws and are designed to withstand shear and tension forces, while screws are principally designed to withstand tension forces. Bolts and nuts can be made using various materials, and the variety of materials used to make the fastener will influence its solidarity, corrosion resistance, and cost. Bolts are tightened and loosened utilizing a tool like a wrench or an attachment, while nuts are fixed and released utilizing a device like a screwdriver or a drill. Bolts are viewed as more durable than nuts and are commonly utilized in applications where a lot of force is applied to the fastener.