13 Different Types of Nuts (Mechanical) – and Their Uses [With Pictures & Names]

![13 Different Types of Nuts (Mechanical) - and Their Uses [With Pictures & Names]](https://engineeringlearn.com/wp-content/uploads/2021/12/Nuts-1024x539.jpg)

Types of Nuts (Mechanical) – and Their Uses [With Pictures & Names] :-

Different Types of Nuts

1. Acorn Nut: ( Types of Nuts )

An acorn nut is the one which is also referred to as a crown hex nut or a blind nut or a cap nut or domed cap nut or dome nut which is known as a nut that has a domed end on one of its side. Once these nuts are found being used together along with a fastener which is found having the threads using an external thread mandatorily the male one, then the domed end is known to be the one which most commonly seems to be responsible for enclosing the thread which is external in order to either protect the thread or for protecting the nearby objects from direct contact with the thread.

Acorn nuts are referred to as the ones which are usually found being made up of brass, steel, stainless steel which are found having a low carbon content or nylon. These are the types of material which are found being chrome plated and are also found having a mirror finish of the same product.

Most commonly there are two types of acorn nuts which are known to human beings. It is also referred to as the low acorn nut or the standard acorn nut whereas the other one is referred to as the high acorn nut. The high acorn nut is the one which is known to be wider as well as higher which with its property is found being responsible for protecting the studs that are observed to be extra-long. There are also observed the self-locking acorn nuts which are the ones that most commonly have a distorted thread in the hex area in order to create a tight friction fit in order to prevent the nut from vibrating or from being loose.

2. Barrel Nut: ( Types of Nuts )

A barrel nut is also referred to as a cross dowel or a dowel nut which is found being made up of the material steel and is known to be a specialized nut which is very commonly used in the aerospace and is also found being read to use for fulfilling the furniture purposes.

These are the types of nuts which are mostly found having very thin bolt sheet along with the metal parts to a larger as well as often billet or the forged parts. The nut need to sit in a hole inside the forging as well as a standard bolt also needs to be threaded so that the barrel nut works properly from outside the sheet metal. Barrel nuts are the ones which are preferred for over a standard nut as well as bolt as they are the ones which do not require a flange for being machined or forged onto the receiving part. This is responsible for reducing its weight.

3. Furniture Cross Dowel Barrel Nut: ( Types of Nuts )

Furniture cross dowel barrel nuts are referred to as a the nuts which are found being designed in a shape similar to a cylinder which are found being used specifically with the bolts used in the furniture that act as a connector for joining two pieces of wood. The threaded hole of the nut which is present inside is the one which is most commonly found to be an unusual one and thus it passes through the sides of the dowel.

The process of installation is that the pieces of wood needs to be joined when they are being aligned after which the bolt hole is found being drilled through one piece of the wood and into the other. Barrel nuts are the ones which are also found quite common in the flat-pack furniture wherever the long bolts as well as the barrel nuts are the ones which are found being used to hold together the T joints.

4. Cage Nut: ( Types of Nuts )

A cage nut or a caged nut is also very commonly known as a captive or a clip nut which is found consisting of a square nut in a spring steel cage and is the one which is wrapped around the nut. Whenever the wings are found being released they are responsible for holding the nuts in particular position behind the hole. Cage nuts are found being used from the year 1952 and 1953. The design of a cage nut was the one which is found requiring the insertion tools in order to install the cage nut into the hole. The newer designs are the ones which also feature a squeeze as well as they release the tab which allows for the tool-less installation.

The square-hole cage nut are technically known to be those nuts which can easily be used at al those places wherever a square hole is found being punched as per its need. This is an older type of captive-nut which is found using a spring clip that usually holds the nut as well as slides on the edges of a thin sheet.

The nut is found having its application usually in the slightly loose cages which are found allowing the minor adjustments in terms of its alignment. This is responsible for reducing the likelihood wherein the threads gets stripped while the equipment installation as well as the removal. The dimensions of the spring steel clip is responsible for determining the thickness of the panel for which the nut is found being clipped. In this case the clip dimensions are responsible for determining the distance within the panel edge and the hole.

5. Clip-On Nut: ( Types of Nuts )

A clip-on nut is referred to as the one which is also termed as a sheet metal nut or a speed nut. Clip on nut is known as a type of nut which is particularly designed in order to be clipped to the sheet metal. These are the type of captive nut which is most commonly made up of a cage nut.

Types of Clip-On Nut

Clip on nuts are the ones which are most commonly found in many forms based upon: where they clip on, shape, and type of thread. Each clip-on nut is perfectly designed even for the small range of sheet metal gauges. It is important to note that these are the types of clips which are found being made up of spring steel.

a) G-Nut

A G-nut or G-style nut is referred to as one of the same type of nut which is found being shaped like G shape along with the clips as well as the edge of a sheet metal object. These types of nuts are quite different from all the other types of nuts as it is usually found being meant in order to clip over a small flange at the edge of metal. The threads which are developed are observed to be an integrated nut which has a special boss in order to sit in a hole of the sheet metal.

b) J-Nut

A J-nut is referred to as that nut which is found clipping into the edge of the sheet metal. This type of nut is named in such a way as it is shaped in the shape of an alphabet J wherein the thread is found to be at the longer side of the “J”. The short retaining leg is not allowed in order to float more, this is found being responsible for the misalignment whereas the nut is found to be free to un-clip the sheet metal as well.

c) S-Nut

A S-nut is also termed as a S-style nut which is named due to the exterior shape of the nut like the alphabet S. These are the types of nuts which are particularly designed in order to clip at the edge of a any metal sheet metal. These are known as threads which are found being provided by an integrated nut only.

d) Square Style Nut

A square style clip-on nut is referred to as that which is not suitable for clipping at the edge of the sheet metal although the edges of a square hole or slot. It is also termed as a square nut which has a sheet metal retainer which protrudes down the two sides of the nut. These legs are found being formed in order to have the lips which usually grab onto the sheet metal object. Until the nut is tightened, you will be able to observe it floating in the hole or at the slot only when the nut is found being fully tightened as it presses the lips which are present at the retainer outside and thus anchors itself in its required place.

e) U-Nut

A U-nut is referred to as that technical instrument which has same properties as that of a J-nut except their both the legs which seem to be of the same length. This is what is helpful in retaining the clip which seems to be usually formed on the leg excluding the threads. This is responsible for helping the nut into the screw down position. The threads which are found in these types of nuts are technically the same as those which are present in the speed nut style which might get integrated along with the nut or might have found other major portion which is usually known to be tapped.

There are the standard as well as the wide-panel versions which are commonly known to us in the U- nut type. The standard version is found having a solid hinge section, whereas the wide-panel version is found having a longer hinge along with the centre section cut-away to let it help more for the easier installation.

6. Coupling Nut: ( Types of Nuts )

A coupling nut is also termed as extension nut which is a non-other than a fastener which is fully threaded for the purpose of joining the two male threads which are most commonly a threaded rod. The outer side of the fastener is usually found having a hex so that the wrench can hold it freely. There are variations which usually include the reduction of coupling nuts, for the purpose of joining two different sizes of threads along with the sight hole coupling nuts which are found having a sight hole which is made to observe the total amount of engagement along with the coupling nuts that are found being accompanied with the left-handed threads. ( Types of Coupling )

These are the nuts which are found being used in order to make up the long rod assemblies from shorter lengths of the rods. The rods are also threaded along with the coupling nut for a particular distance only.

Coupling nuts are the found having their application in tightening a rod assembly in the inward direction or in order to press a rod assembly in the outward direction. The connecting nuts are the ones amongst the frequently used nuts for making the bearing at home as well as the seal pullers or the presses at home. The main advantage of a connecting nut as compared to a standard nut in this application is that with respect to its length there is a greater number of thread which is observed to be engaged along with the bolt. This is the reason which allows you to spread the force over a larger number of threads, which is responsible for reducing the possibility of stripping or galling the threads due to the effect of heavy load.

7. Flange Nut: ( Types of Nuts )

A flange nut is referred to as a nut which is found having very wide flange at one of its end which usually acts as a washer which is already integrated. This is what serves in the distribution of the pressure of the nut over one of its part being secured or reducing the chance of damage for the part to make it less likely to loosen as a result for an uneven fastening surface. Flange nuts are the ones which are commonly found in the geometrical shape of a hexagon and which is also made up of hardened steel along with being coated with zinc.

The flange can be observed to be serrated in order to provide any sort of locking action. Taking your attention towards the serrated flange nut then it must be said that the serrations are particularly angled in such a way that they keep the nut away from the rotating in the direction that would possibly be responsible for losing the nut. These serrations are the ones which cannot be used along with a washer or at any such surface without being scratched. The serrations are responsible for helping to prevent the vibration of the nut from moving the fastener. This is what is responsible for maintaining the actual holding power any type of nut.

Flange nuts are provided with a swivel flange which is responsible for giving more stability to the structure and does not at all affect the finishing of the product similar to a serrated flange nut. Swivel flange nuts are the ones which are most commonly used for the application of joining materials like wood and plastic.

8. Self-Aligning Nut: ( Types of Nuts )

A self-aligning nut is also termed as a spherical nut or a levelling nut which is one amongst that type of nut that is mostly found having its applications at all those places wherever the fastener is not set at an angle perpendicular to the surface of the nut anchors. These are the ones which are commonly used in the industries like aerospace. If these were the types of nuts which were changed then it would be replaced with any other type then not used the object would have to be spot faced perpendicular to the fastener.

9. Insert Nut: ( Types of Nuts )

An insert nut is referred to as that nut which is found providing a socket that should specifically be fully threaded in order to resolve all the purpose of a wooden work piece, which seems to be quite similar to a wall anchor. Insert nuts are found being inserted at the holes which are found to be pre-drilled one amongst the two means: either screw in or hammer in. In both the cases, the external protrusions is observed biting inside the wood which is directly or indirectly responsible for preventing the nut from either turning or pulling out.

Insert nuts are found having their merits over the other nuts like barrel nuts or T-nuts, as they are the ones which are known to be installed from either of the one side of the work piece.

10. Knurled Nut: ( Types of Nuts )

A knurled nut is referred to as that nut which is knurled outside the surface. This is what is responsible for tightening the nuts by the impact of a bare hand and which can secure the nut into a handle or a cover

Knurled nuts are the ones which are found to be used commonly in any of the application where these fasteners will not be placed permanently, which means they will be removed at a regular interval of time and will not need any structural support. These are the types of nuts which are most commonly found having their application on the electrical panel covers, precision measuring tools, squares, as well as the service covers. The main advantage of using a knurled fastener is that it will help in improving the ease of removal, decreases the possibility of being over-tightened, which might not require any tools in order to manipulate the fastener.

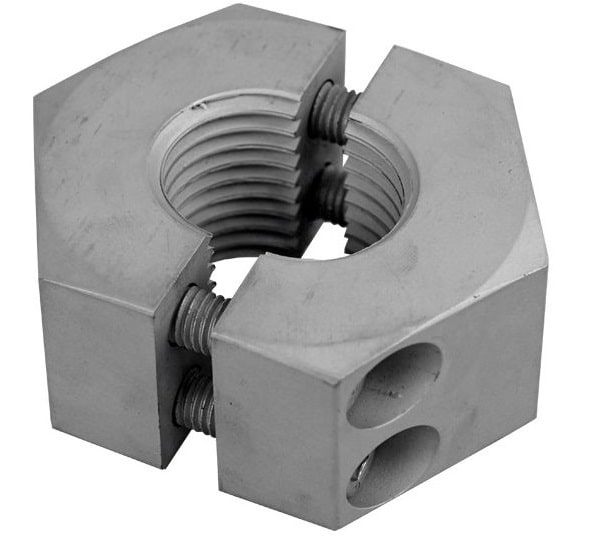

11. Split Nut: ( Types of Nuts )

A split nut is referred to as a nut that is named in such way as it is split lengthwise into two different pieces of the opposed halves so that the female portion of the thread can be opened as well as gets closed over the male thread of a bolt or the lead screw.

This feature is the one which allows the nut to move along the screw only when its open, without turning the screw or vice versa. Once the nut is closed it will resume the normal movement of a nut on a screw. This will include the axial rotation.

There is a split nut assembly which is commonly used for its positioning systems. For instance, the best example can be a lead screw of a lathe. This is one of the best machine element that will definitely make the single-point threading practical on manual as well as on the non CNC lathe machines. Usually the screw as well as the nut are also oiled for fulfilling the lubrication process. These are the types of provisions which are found prolonging the service life of the threads by minimizing the wear and tear.

12. Square Nut: ( Types of Nuts )

A square nut referred to as a nut which is designed in a very uncommon a nut pattern with four sides. In reference to its comparison with the standard hex nuts, these nuts are the ones which are found having a greater surface in contact with the part which is being fastened and thus provides a greater resistance in terms of loosening or the resistance of tightening. Unlike the other nuts these are the nuts which are less likely to become rounded-off once they get loose or tight cycles. Square nuts are one amongst the typically mated bolts along with the square-headed face. These nuts are found being used along with the flat washers in order to avoid the damage from the sharp edges.

13. T-Slot Nut: ( Types of Nuts )

A T-slot nut is referred to as that nut which is commonly used along with a threaded clamp in order to position as well as secure the pieces which are found being working on in different workshops. The T-slot nut is the one which is found sliding along with a T-slot track, which is a set in the workbench or a band saw. T-slot nuts are the ones which are found having their application with the T-slot structural frames in order to build a variety of industrial structures as well as the machines.

A T-slot bolt is found having higher strength as compared to a T-slot nut or a hex-head cap screw.