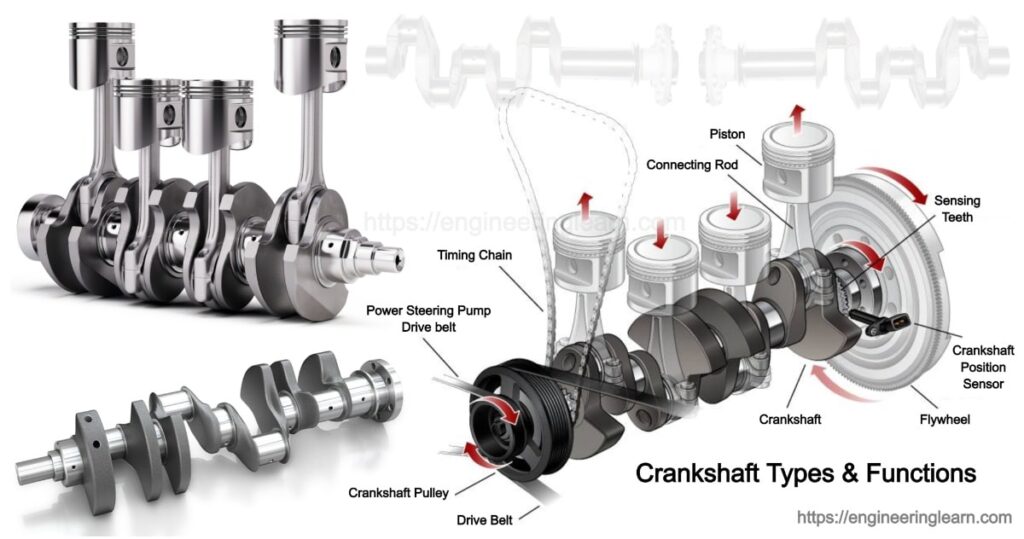

Crankshaft Types & Functions

What is Crankshaft?

Crankshaft Types, Functions and Working Principle :- A crankshaft refers to a rotating shaft which is used for converting the reciprocating motion of a piston into a rotational motion. These shafts are commonly used in the internal combustion engines to with an aim to perform such operations.

Crankshafts is found consisting a series of cranks along with the crankpins to which the connecting rods are attached. The crankshaft includes at least one shaft which rotates inside the engine block. It rotates with the help of the main bearing. The crankpins is rotated between the connecting rods with the help of the rod bearings.

Construction of Crankshaft

Crankshafts are built using the metals like cast iron. The metal is taken in the molten form and is then poured in a mold during the process of casting whereas the modern crankshafts are made from the forged steel that is mostly used in some performance engines.

The process of making a crankshaft includes heating a block of steel until it gets red hot. Once it gets hot its shape is formed using an extreme high pressure. The heat-treatment is either alloyed steel or nitride steel materials which are used. The crankshafts are also surface-hardened.

Function of Crankshaft

- There are endless functions which gives a smoother drive to the motors with the multiple cylinders.

- Converting the linear motion of the piston into the rotational motion is also one amongst its functions.

- The power is produced through the combustion of the fuel-air mixture.

- The shaft of the crankshaft is bored with some holes which feeds the motor with the required quantity of oil. This oil is mainly used to smoothen the movements.

- Crankshafts also functions as load bearing as the load gets distributed during this process.

- One of the load is the severe bending and the torsional stress wherein the pistons are connected to the crankshaft through the connecting rod.

- It must be noted that the rotary movement of the crankshaft accelerates and decelerates constantly where the further loads of torsional vibration is added.

- The crankshaft is mounted inside the engine block with following other parts which are as follows:

- Pistons

- Connecting rods

- Flywheel

- Crankshaft

- The secondary function of a crankshaft is to transmit the power of other systems of the engine:

- valve timing

- oil pump

- cooling (water) pump

- compressor of air conditioner

- An Alternator

Fitting The Crankshaft

The crankshaft is set into the engine block through the main journal. The connecting rods are fixed to the journals of the crankshaft. Whereas on the opposite side of the conrod journals, the crankshaft has the counterweights which is used to compensate the outer moments, to minimize the internal moments and thus reduce the vibration amplitudes and the bearing stresses.

One end of the crankshaft is connected to the flywheel and the other end to the valve timing gearing. The number of main journals and conrod journals depends upon the number of cylinders and the types of the engine like V-type, straight etc.

Both the main journal as well as the conrod journal has lubricated crankshaft orifices or oil bore through which the oil flows whenever the engine runs. The exact place of fitting a crankshaft is on the main journals, between the crankshaft and the engine block. Their main role is to reduce the impact of friction through a layer of anti-friction material which comes in direct contact with the block mounts of the engine.

Working Principle of Crankshaft

Considering the multi-cylinder engine, these are more complex engine as the crankshaft is used whereas in small engine the simple design is quite sufficient. A crank pin to which the big end is attached completes the moment within the two motions. This is an additional bearing surface which has an offset axis from that of the crank. The flywheel or the crankshaft pulley is mounted on the crank in order to store the energy which is generated which can be used for the further work. A flywheel is also found reducing the pulsation characteristic of a four-stroke engine.

The crankshaft is mounted inside the main bearing in order to give smooth and vibration free running of the engine. The quantity of bearing of the engine depends upon various factors like the design of an engine, a number of cylinders, the design of crankshaft etc. But as there are always at least two bearings, one is placed at the drive end and the other one at the non-drive end. In case, everything goes fine, there is a rare need for replacing the engine bearing.

The counterweight is used to reduce the bending load on the crankshaft which also helps the engine not to shake whenever the mechanism of the crank is rotating. The Crankshaft balancing mostly depends on the counterweights. The Engine crank web is the portion of crank between the crankpin or the adjacent crankpins and the shaft which is also known as a crank arm.

Types of Crankshaft

Two types of crankshaft are produced which are commonly known as cast and forged. The counterweights can be also forged directly into the crankshaft or can be bolted-on with the threaded bolts. All the pistons of the internal combustion engine transmit their load at the crankshaft. The crankshaft has to undergo high torsional forces, bending forces, pressures and vibrations. Let’s study more about the types of crankshaft:

1. Cast Crankshaft: (Crankshaft Types & Functions)

These refer to as the types of crankshaft which are commonly found near a long time and are mostly a lot in diesel and petrol engines. The name clearly suggests that these are made from the malleable iron through a casting process. These are quite economical in working therefore are commonly selected by the manufacturers.

A flat plane crank is the one wherein the journals are kept 180 degrees apart from the all in-line four engines. Whereas when it comes to a cross-plane crank they need a mold of multiple parts because the journals and counterweights are not that symmetrical. The cast cranks are hardened through the flame in order to improve the wear resistance in particular areas.

2. Forged Crankshaft: (Crankshaft Types & Functions)

These are a comparatively more robust crankshaft which are more commonly found especially higher stressed engines which comes standard with some 16v engine. Creating a forged crank is totally different. There are different sets of dies which are machined together to the approximate shape of the crank.

These dies are set in a very large hydraulic press which has a clamping force of many tons. A hot bar of very high-grade steel alloy is placed at the bottom die and then the dies are closed. Once the dies are closed the metal get squeezed very tightly after which the material is compacted and aligned for better casting process. These type of cranks are also hardened like the cast cracks but using the Induction Hardening.

3. Billet Crankshaft: (Crankshaft Types & Functions)

Billet crankshaft are one of the best type of crank which once can have in the engine which is normally used to manufacture this kind of crank. This usually contains materials like nickel, chromium, aluminum, and molybdenum amongst other elements. These cranks are most common due to the lowest crankshaft machining time. Also these require a minimal balancing due to the uniform makeup of the material.

Best Crankshaft Material

A Crankshaft is most commonly formed from materials like Carbon Steel, Nickel Chrome or other Alloy Steel. The alloy elements in the carbon steel are manganese, chromium, molybdenum, silicon, cobalt and vanadium. Sometimes aluminum and titanium are also used. It is a belief that if you select these above mentioned material for a crankshaft then you will hardly require a crankshaft repair or crankshaft replacement.

Crankshaft Components & Design

The essential components of crankshaft include: (Crankshaft Types & Functions)

- Main Journals: Main journals are responsible for carrying the main bearing and also declare the axis of rotation of the shaft.

- Crank pins: Crankpins are the ones which allows the connecting rod to be attached to it.

- Crank webs: Crank webs connect the crankpins to the main journals.

- Counterweights: Counterweights offers balancing which are mounted to at the webs.

The design of a crankshaft is based on the ability of firing and the number of cylinders of the engine. It is also determined by the design of the engine and the numbers of crankshaft bearing and its stroke size.

Crankshaft Lubrication

Lubrication plays a very vital role in the efficiency of an engine and also enhances its working mechanism which involves the rubbing of two metal parts. The main aim is to avoid the unnecessary wear on crankshaft, main journals and rod journals which both ride on a film of oil. This film of oil is responsible for siting on the surface of bearing. The oil is supplied to the main bearing via oil galleries of the engine block which leads to each crankshaft saddle and matching the hole in the bearing shell which collects the oil to the journal.

How A Crankshaft Works?

The working of crankshaft is easy, it is not at all complex. There is a respectable distance between the center point of the main journal and the crankshaft pin. This distance is referred to as the crank radius or crank throw. Its measurement tells us the range of piston which it travels as the crankshaft rotates.

The top to the bottom distance covered is known as stroke and the piston stroke is twice of the crank radius. The rear end of the crankshaft extends outside the crankcase which is supported with the flange of the flywheels. This flange is a precision machined part which is bolted to the flywheel. The crankshaft is usually bolted to the ring gear, specifically in an automatic drive.

General Crankshaft Faults

Very rarely there are issues found on a crankshaft, only in the case when the engine experiences any of the following extreme conditions. The component of engines are quite reliable and sturdy but some common fault mentioned below can cause failure:

1. Worn journals

Worn journals is caused due to insufficient oil pressure. The crankshaft journals comes in direct contact with the bearing surfaces which gradually increases the clearance and decreases the oil pressure. Worn journals can cause very serious problem to the engine if not taken care of. It can also lead to destroying the bearing and can cause huge damage to the engine.

2. Fatigue

Fatigue refers to as the constant forces on the crankshaft which lead to the fractures. This problem usually occurs on the fillets where the journals and the web are joined together. The cracks which develop can be inspected on crankshaft with the use of a magna fluxing. The majority of steel crankshaft failure occurs due to fatigue failure that can originate at the change of cross-section.

3. Failure due to Vibration

Whenever the engine is running with heavy vibration during torsional vibration, it can lead to a crack in the crankpin and journal.

4. In adequate amount of lubrication

In case the lubrication of bearing in the crankshaft is in adequate then it can lead to complete wiping out of the bearing and failure of the crankshaft.

5. Over Pressurized Cylinder

It is possible that there is a hydraulic lock inside the liner caused due to extreme pressure at the crankshaft or even bent.

Reasons for Crankshaft Misalignment

- Damage or wipe-out of the main bearing

- Loose engine foundation bolt leading to vibration

- Deformation of ship’s hull

- Crack in the bearing saddle

- Loose main bearing bolt leading to damage of main bearing

- The high bending moment is applied on the crankshaft due to the excessive force from the assembly of the piston.

- Grounding of the ship

- Crankcase explosion or fire

- A defective or worn out stern tube or intermediate shaft bearings

- Loose or broken chokes in the foundation

- Bearing pockets cracked

- Bedplate deformed – transverse girder damaged

- Tie bolts slack or broken

- Weakening of structure due to corrosion