2 Stroke Engine: Introduction, Construction, Application, Diagram & Working Principle

Introduction

2-Stroke Engine: – A two-stroke engine refers to a type of an engine which undergoes internal combustion and completes the power cycle with only two strokes of the piston during one revolution of the crankshaft only. The two stroke engine was introduced by Karl Benz who got it registered into the books in the year 1879. Karl Benz was also the one who started the luxurious brand Mercedes-Benz. About ten years ago, the motorcycles with two-stroke engines were the prime choice of the bike lovers.

Construction of a 2-Stroke Engine

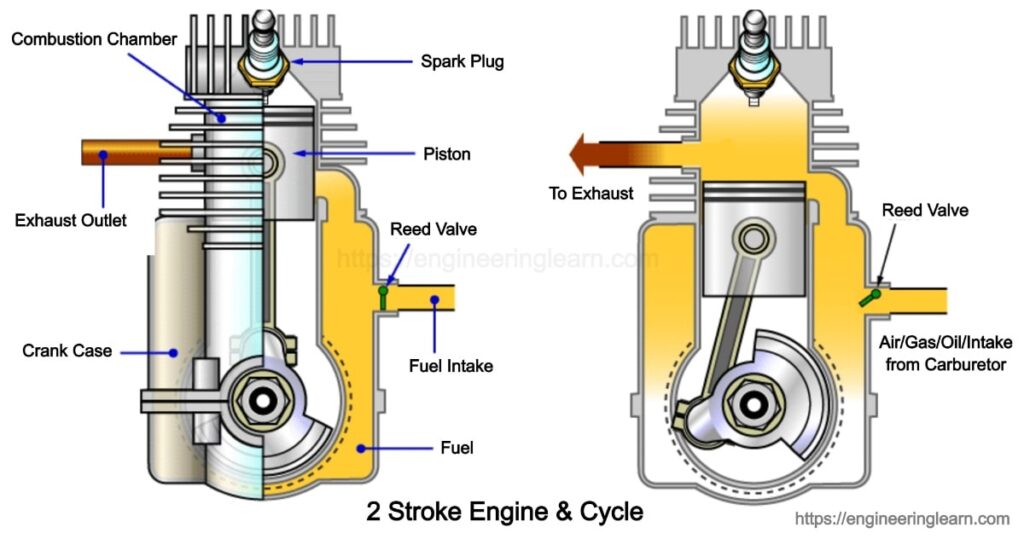

The construction of a two stroke engine consists of the following parts which are of the utmost importance:

1. Piston

Piston is used to transfer the force of gases which are expanded to the mechanical rotation of the crankshaft with the help of a connecting rod.

2. Crankshaft

Crankshaft is used to reciprocate the motion into a rotational motion.

3. Connecting Rod

The role of a connecting rod is to transfer motion from a piston to the crankshaft. The connecting rod can also act as a lever arm.

4. Flywheel

Flywheel refers to a mechanical device which is used to store the energy.

5. Spark Plug

The role of a spark plug is to deliver an electric current to the chamber which in turn ignites the air-fuel mixture which leads to an abrupt expansion of the gases.

6. Counter Weight

The counterweight on the crankshaft has a role of reducing the number of vibrations which are caused due to the imbalances in a rotating assembly.

7. Inlet and Outlet Ports

The role of an inlet and outlet port is to allow inlet of fresh air accompanied by fuel to enter and exit from the cylinder.

2-Stroke Engine Cycle

It is very important to know the working cycle of a two stroke engine. Scroll down to know it in detail:

Down Stroke

In a down stroke engine the piston moves from the Top Dead Center (TDC) to the Bottom Dead Center (BDC) which lets the fresh air enter into the combustion chamber. The mixture of the fresh air and fuel gets inside the combustion chamber through the crankcase. In the down stroke, the rotation made by the crankshaft is at an angle of 1800.

Up Stroke

In the up stroke the condition is reversed. The piston is moved from BDC to TDC which in result mixes the fuel and air and compressed them which in turn ignites the spark plug. The inlet port is kept open during the upstroke due to which it sucks the mixture inside the crankcase.

Whenever the mixture is pushed inside the combustion chamber, a sort of vacuum is created as there is no mixture left behind in the crankcase. After this the mixture is ready to move into the combustion chamber but remains in the crankcase until the piston moves till the TDC.

Once the first down stroke is complete, the second down stroke onwards the gases from the exhaust move out from one side meanwhile the fresh mixture enters into the combustion chamber as the partial vacuum is created in the combustion chamber after the removal of the exhaust gases. This process happens simultaneously which makes it a 2-stroke engine.

Once the exhaust gases are exited, there is entrance of fresh air from one side and fuel from the other side which move into the combustion chamber due to the effect of the partial vacuum which is created in the combustion chamber after the removal of the exhaust gases.

Applications of 2-Stroke Engine

- The two-stroke engines are perfect when the design priority includes simple, lightweight structure and high power weight ratio.

- These engines are lubricated by the old and traditional method of mixing both the oil and fuel together. This is the reason which makes them high in demand for their use as a handheld tool like a chainsaw.

How to tell the difference between 2-stroke and 4-stroke

The basic parts of the 2 stroke engine remain the same as that of a 4-stroke engine but the main difference is the charging delivery inside the engine i.e. the air-fuel mixture.

- A 2-stroke engine is found having no valves, instead has the ports which do their job well. The movement of the piston is responsible for the opening and closing of the ports.

- A 2-stroke engine has a transfer port which is used to move the fresh charge from the crankcase to the combustion chamber.

- As the motor has a piston in it, it slightly differs from the conventional ones. The head of the piston has a hump.

Different Designs of 2-stroke engine

1. Reed inlet valve

The reed valve is a simple valve which is a highly effective form of check valve that is commonly fitted in the intake pathway of the port of the piston controller. This helps in asymmetric intake of fuel charge, improves power and economy, and widens the power band. These type of valves are mostly used in motorcycles, and marine engines.

2. Rotary inlet valve

The intake track of these valves open and close by the members which are indulged into the consistent rotation process. This type of activity is sometimes seen in bikes wherein a slotted disk is attached to the crankshaft that covers and uncovers the opening in the end in order to allow charge to enter during one portion of the cycle.

3. Cross-flow scavenging

In these types of engines there are two ports one is transfer and the other is exhaust port which are situated opposite to the cylinder. The deflector of the piston which is on the top, fetches the fresh intake charge into the upper part of the cylinder, which pushes the residual exhaust gas downwards from the exhaust port.

4. Loop scavenging

Loop scavenging uses a carefully shaped and positioned ports which directs the flow of fresh mixture towards the combustion chamber as soon as it enters the cylinder. The fuel-air mixture strikes the head of the cylinder, after this it follows the curvature of the combustion chamber, and then it is deflected downwards.