Control Valve: Types, Parts, Working Principle, Applications, Materials, Advantages & Disadvantages

What is a Control Valve?

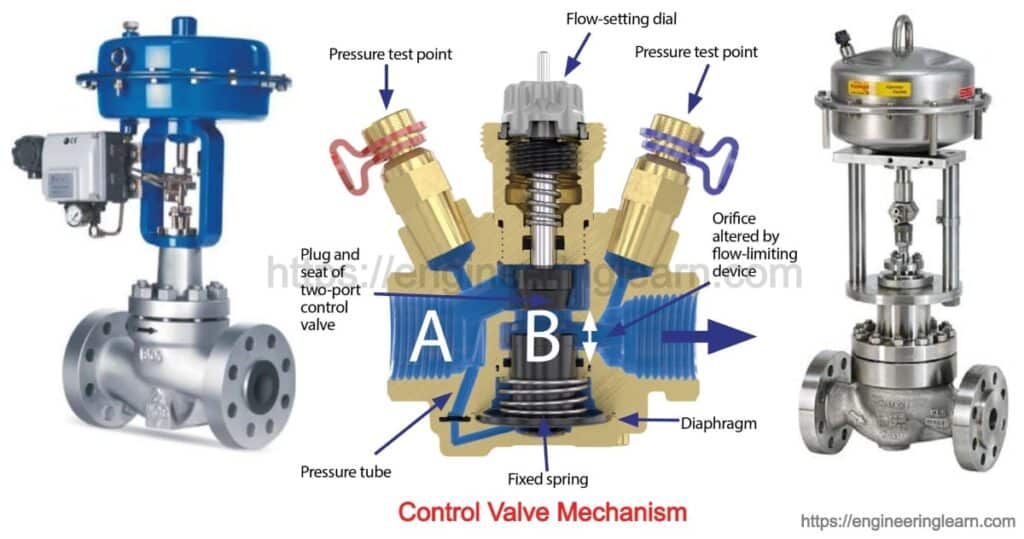

Control Valve: Types, Parts, Working Principle, Applications, Materials, Advantages & Disadvantages :- Control valve is used for controlling the flow of fluid by varying the size of passage of flow according to the controller and enable direct control over the flow rate. This results in control over process quantities like temperature, liquid level and pressure. It is termed as final control element in automatic control terminology.

The principle behind the working of control valve is that it can control the fluid rate which is based on controller input.

Working Principle of Control Valve

The closing or opening of automatic control valves can be done by pneumatic or hydraulic actuators, electrical actuators. With modulating valve which is set at any position between fully closed and fully open, desired degree of opening is determined by the valve positioners.

Generally air actuated valves are used due to their simplicity because they require only compressed air supply but the electrically operated valves need additional switch gear and cabling and hydraulically actuated valves need return lines for hydraulic fluid and high pressure supply.

Pneumatic control signals are based on pressure of range 0.2 bars to 1.0 bar and an electrical signal of 4mA to 20mA for industries or 0 V to 10 V for heating, ventilation and air conditioning systems. Electrical control includes smart communication signal which is superimposed on 4mA to 20mA control current, so that valve position verification can be signaled back to controller. The highway addressable remote transducer protocol, Profibus and field bus foundation are the common protocols.

Main Parts of Control Valve

- Valve actuator: It is used to move valve modulating elements like butterfly or ball.

- Valve positioner: It is used to check that desired degree of opening is reached or not which overcome the issues of wear and friction.

- Valve body: It contains modulating element, globe, a plug, butterfly or ball.

In case of air operated valve, two control actions are possible.

- Air or current to close: Increment of flow restriction as the control signal value increases.

- Air or current to open: Decrement of flow restriction as the control signal value increases.

Failure to safety mode can also take place

- Air or control signal failure to open: On the failure of compressed air to actuator, under the backup power or by spring pressure the valve gets opened.

- Air or control signal failure to close: On the failure of compressed air to actuator, under the backup power or by spring pressure the valve gets closed.

The operation of modes of failure is required by the failure to safety process control specification of plant. In case of delivering chemical it may fail closed and for cooling water it may fail open.

Types of Control Valves

Control valves can be differentiated on the following basis:

A) Based on Pressure Drop Profile

1. Low Recovery Valve

These types of valve regain very small amount of static pressure drop from inlet to outlet’s vena contracta and are characterized by high recovery coefficient. Examples: angle valve, globe valve.

2. High Recovery Valve

These types of valves regain most of the static pressure drop from inlet to outlet’s vena contracta and are characterized by low recovery coefficient. Examples: Butterfly valve, ball valve, plug valve, gate valve.

B) Based on Movement Profile of Controlling Element

1. Rotary Valve

Rotary Valve : In this type of valve the disc of valve rotates. Examples: butterfly valve, ball valve.

2. Sliding Stem

In this type of valve the valve plug or stem moves in a straight lime motion or linear. Examples: angle valve, globe valve, gate valve, wedge valve.

C) Based on the Medium of Actuation

1. Manual Valve

These types of valves are actuated by hand wheel.

2. Pneumatic Valve

Pneumatic Valve : These types of valves are actuated using compressible medium like hydrocarbon, nitrogen or air with a piston cylinder or piston spring type actuator and a spring diaphragm.

3. Hydraulic Valve

These valves are actuated by non compressible medium like oil or water.

4. Electric Valve

These valves are actuated by an electric motor.

Wide variety of control operation and valve types exist but have mainly two form of actions which is the rotary and the sliding stem. But the most common type of control valve are V – notch ball, sliding stem globe, angle types and butterfly valve.

D) The Common Types of Control Valves are

Sliding stem

- Angle body valve

- Globe valve

- Angle seat piston valve

Rotary

- Ball valve

- Butterfly valve

Other

Applications of Control Valves

- Used for on – off applications.

- It can be used for throttling purposes.

- It can be used for pressure and flow control.

- Low pressure applications and large flow control.

- Can be used for corrosive liquids at low pressure and temperature.

Advantages of Control Valves

- It provides control over flow rate.

- It has effective and rapid functioning.

- It has durable service life.

- It has compact design which facilitates minimal consumption of space.

- It have minimum pressure drop.

Disadvantages of Control Valves

The only disadvantage of control valves is that they require control signal throughout its working period.

Materials of Construction of Control Valves

Carbon steel material is chosen for the use of non corrosive use. Stainless steel is used for seat rings and valve plugs. For less corrosive applications, stainless steel is used for making valve housing. Exotic alloys like titanium are used high corrosive fluids.

Control Valve Actuator

Pneumatic actuating devices either piston actuated or spring opposed diaphragm are used by more than 90 percent of the control valves.

The diaphragm or spring actuator are more popular in comparison to the piston actuated because of its ability to fail safe and simplicity while more dynamic stiffness is provided by the piston actuators because high air pressure is used by them and are highly compact than spring opposed diaphragm actuators.

There are electric and hydraulic actuations which are used generally for special applications. Due to limited reliability and higher cost their uses are limited.

Image Source :- cibsejournal