Angle Valve: Definition, Applications, Features, Working, Material, Method & Replacement

What Is an Angle Valve?

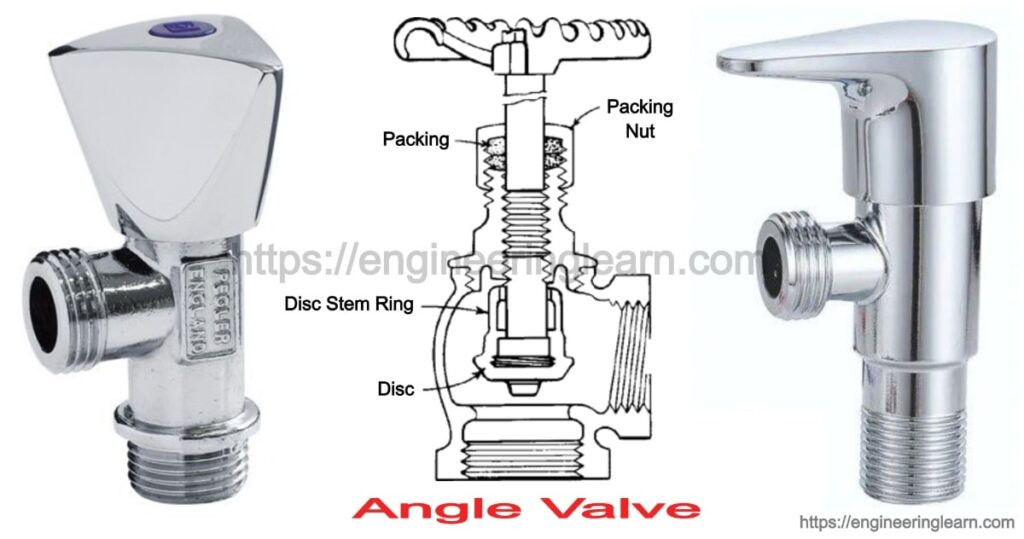

Angle Valve: Definition, Applications, Features, Working, Material, Method & Replacement :- An angle valve consists of an inlet and an outlet port which are at 90 degrees to each other. The angle valve comes in the category of manual valves. This valve is widely used to stop or control the flow of a fluid in a pipe. Due to this it is sometimes called simply as stop valve. Stop valves are the valves that completely stop the flow of the fluid inside the pipe. However angle valves are more commonly used as regulating devices in residential plumbing and industry.

The angle stops typically have an oval knob or twist handle. In public places, where there is a risk of theft or stealing, removable handles provides the best solution. The previous versions of angles’ knobs need to be rotated many times in order to shut off the flow of liquid. But the modern angle knobs are provided with angles with a ¼ turn handles to shut off the flow as quickly as it is possible in emergency situations. Angle valves are the most commonly used valves around us. For example, there is frequently one connected to toilet and two to faucet allowing us to work on the repair of faucet without having to shut off the water of the whole house.

Applications of Angle Valves

Angle valves are mainly used for two reasons:

- When there is a need of upgrading or renewing the faucet or other fixtures. Instead of cutting the flow of water in the entire house or building, simply the angle valves can be used to shut off the water to just that single apparatus or fixture which needs to be fixed.

- At the time of water leakage or even complete burst, you can use the angle stop to shut off the flow to that appliance or fixture until the proper repairs are made.

Features and Working of Angle Valves

An angle valve is used in many applications. It has diverse applications ranging from domestic uses in home to industrial uses. The angle valve is a crucial part of many types of machinery and helps in safe processing of a variety of liquids, chemicals, and gases.

Angle valves possess many types of designs and sizes. The extent of the project and the dimensions of the piping influence the size and design. Giant and higher quality angle valves are generally suggested for heavy processes. Depending upon the mechanical functions and materials used in valves each angle stop valve is designed to handle a specific amount of pressure.

Types of seal, plug, and stem are important factors for determining the efficiency. The main function of angle valves is to regulate or control the flow and to decrease the pressure. They may also have some influences on temperature.

The methods used to reach these functions can be different. The best part is that angle valves can be used as-

1) shutoff valves

2) needle valves

3) check valve

4) Stop-check valves.

Material Selection of Angle Valves

Copper is the ideal material for manufacturing of angle valves. This is because it has higher durability (relatively longer period of time) and provides good service as compared to other metals. In comparison to copper, zinc alloy ages fast, and have a shorter life service. Plastic or PVC is does have an attractive appearance and have a short life. The shine and luster of metal alloys gives a good look and better appearance.

Method of Operation of Angle Valves

The angle valves are also known as air-operated angle seat valves or externally operated valves. The angle valves are controlled by a pressurized pilot medium, which is generally air. The valves are equipped with pneumatic actuators. The pilot medium streams into the actuator cylinder under pressure and this causes the piston to work so that the seat seal opens or closes allowing or stopping the flow.

Angle Valves in Home

Generally, the angle valves are needed for the following places in home:

1) Cold water angle stop valve on toilet water nozzle, wash basin, wash basin on the nozzle respectively need a cold and a hot angle stop valves

2) The sump on the sink needs a cold and a hot valve and water heater on the water nozzle needs two cold valves.

Replacement of Angle Valve

There are plenty of reasons for the angle stop valves to be replaced. One of the most common is that when a leakage occurs around the valve. The leakage is the sign for replacing an outdated angle stop valve before it completely bursts and causes major water damage.

There are other reasons for the replacement of angle valves- like the older angle valves normally were never designed to last. After 8-10 years of not being used and just with the first use after installation, the compression part of the valve is liable to fail. Also the modern version of angle stop valves like quarter-turn shut-off valves have a longer working life. They are composed of stainless steel so there is no possibility for water burst and hence no risk of water leakage.

Uses of Angle Valve in Industries

For every mechanical operation in which it is required to control the flow, temperature, and pressure, there is a need for angle valves. The main point is that the valves used for industrial operations must be completely reliable and dependable in order to be sure of safety and efficiency of operations.

Image Source :- encyclopedia2