8 Types of Lathe Chuck [Explained with Pictures]

What is Lathe Chuck?

Types of Lathe Chuck :- A lathe chuck is basically a part of lathe machine which is set up on the headstock of a lathe. The lathe chuck operates either manually or using power supply. The main use of lathe chuck is to hold the material block which is operated upon. It holds the piece to be machines, when it is rotating. It can hold both symmetrical as well as asymmetrically shaped objects (especially the ones lacking radial symmetry). Apart from lathe machines the chucks are also used in places such as milling machine.

What is Lathe Machine?

A Lathe machine can be basically defined as a device that rotates the blocks of a given material in order to make a job. Operations such as grinding and cutting are implemented to the material. Normally lathes are used to shape objects with rotational uniformity. The lathe operates on materials generally made up of-

(It is to be taken care that any material block which is used should be within the size boundaries of the lathe (generally 8” dia and 42” length)

Types of Lathe Chuck

Broadly speaking there are basically seven types of lathe chuck used in lathe machines, namely-

1) Magnetic Chucks

2) Four Jaw Independent Chuck

3) Combination Chuck

4) Three Jaw Universal Chuck

5) Collet Chuck

6) Drill Chuck

7) Air Chuck

8) Hydraulic Chuck

1. Magnetic Chucks: (Types of Lathe Chuck)

The magnetic chuck is used for gripping very lean pieces. These lean pieces are made up of magnetic material which cannot be gripped in an ordinarily chuck. Many a times there is a chance of bending, buckling, twisting or any kind of deformation of the work piece due to pressure of the jaws of ordinary chucks. At such instances, Magnetic lathes are used.

The chuck has either electromagnets or permanent magnets installed in it. It is from these magnets, that the chuck obtains the radiating magnetic flux. This magnetism aids the chuck to hold the work piece.

How the magnetic chuck works-

When the lathe is turned on, the magnetic flux passes through the work piece and holds it. When the lathe is turned off the magnets are removed. The magnets are then brought in contact with high permeable items known as keepers. These keepers short-circuit the flux, thereby preventing the flux from passing through the work piece.

2. Four Jaw Independent Chuck: (Types of Lathe Chuck)

In the four-jaw independent chuck, each of the stepped jaw is separately operated by a different screw. With the help of this characteristic allows the four- jaw independent chuck to fasten any shape. Shapes such as round, rectangular, square, irregular etc can be fastened by this type of chuck using between tow and all four of the available jaws.

Excess features slow down the operation process and also takes a lot of practice to operate on it. This chuck also requires the help of an indicator gauge. The jaws of this chuck are also changeable. The can be used for clamping inside or outside according to the task. As an advantage, the four-jaw independent chuck is the most reasonably priced type of lathe chuck

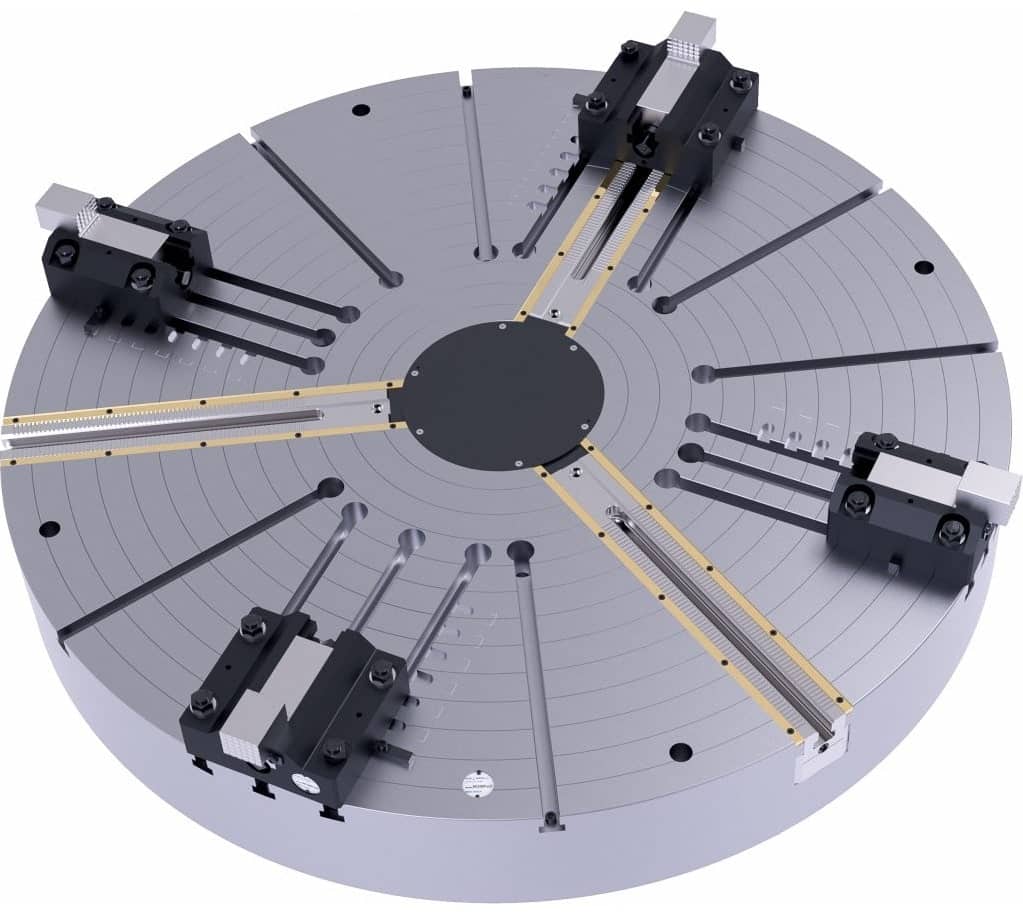

3. Combination Chuck: (Types of Lathe Chuck)

A combination of chuck is used both as a

- Self-centering chuck

- Independent chuck

This specific feature of this chuck helps to make benefits of both the types of chucks. The jaws are operated independently by separate screws. They are also operated by the scroll disc. The frame consists of teeth cut on its bottom which interlocked with the scroll. These jaws along with the screws move radially. This movement takes place when the scroll is rotated by a pinion.

4. Three Jaw Universal Chuck: (Types of Lathe Chuck)

The three jaw lathe chuck is the most widely used chuck. The jaws of this chuck are at an angle of 120 degrees from each other. These jaws are made up of high- quality steel.

When the chuck is operated the jaw teeth are made to connect with the bevel teeth. This interlocking causes a moment of all three jaws either towards or away from the chuck centre. This moment depends upon the direction of rotation of the bevel pinion. The chuck key, which is a square end key, operates the pinion.

The three jaw lathe chuck is generally employed for gripping shapes such as round and hexagonal shaped work pieces. The three-jaw chuck has this unique feature that the job is centralized automatically in very less time. This chuck suffers from a disadvantage that the holding capacity becomes less as only three jaws are used and centering precision is soon lost due to wear.

5. Collet Chuck: (Types of Lathe Chuck)

Collet chucks are generally employed for griping bar stock in factories or industries, where the work is required to be quickly set and accurately centered.

The chuck is connected to the spindle by a nut. A collet is a lean cylinder shaped bushing. This collet has slots cut along its length on its periphery. The inside bore of the collet is of the following shapes- hexagonal, cylindrical, square, etc. This shape depends upon the shape of the work-piece passing through it.

The exterior surface of the collet is tapered. This tapered surface inserts in the taper hole on the body of the chuck. The tail end which is threaded, this tail end interlocks with a key.

When the key is rotated from outside, it draws the collet inside. This leads to the split tapered end to be pressed inside due to the springy movement. This makes the work piece to be firmly held in the chuck with precision. And the work piece is securely and accurately held in the chuck. A number of varieties of sizes of collectors are used for griping different sizes of the bar stock.

6. Drill Chuck: (Types of Lathe Chuck)

A drill chuck is generally used for holding linear shank drill, reamer, or tap for drilling, reaming or tapping operation. The chuck can be mounted either in headstock or in the tailstock spindle. The drill chuck consists of centering jaws. These centering jaws are run by rotating a key.

7. Air Chuck or Hydraulic Operated Chuck: (Types of Lathe Chuck)

The Air chuck or Hydraulic operated chucks are generally employed in mass production work. This chuck has a quick and effective holding calibre. The appliance of air or hydraulic operated chuck is composed of a hydraulic or air cylinder.

This cylinder is fixed at the rear end of the headstock spindle and turns with it. The fluid pressure is conveyed to the cylinder by handling a valve with a lever and the piston will drop within the cylinder. The motion of the piston is imparted to the jaws by a connecting rod and links and the jaws hold the work-piece securely.