Toggle Clamp: Definition, Types, Uses, Mechanism, Parts, Working, Applications & Advantages

What is Toggle Clamp?

Toggle Clamp: Definition, Types, Uses, Mechanism, Parts, Working, Applications & Advantages :- Toggle clamped mechanism can be defined as the simple mechanism which is used to hold instantaneously. In a toggle clamp there is a handle which can be used for operation, for reaching the work piece there is a clamping arm, for multiplication of the force applied linkages are used and for mounting the work piece a base is used. Handle are operated in such a way that it results in moving of clamping arm for holding the work piece and then the clamping force are exerted to the work piece and in this situation the toggle clamped mechanism are used for holding the work piece positively as well as firmly. ( Types of Clamps )

Principle of Toggle Clamp

Clamps in toggle action are generally operated with the help of linkage system of pivots and levers. The levers of fixed length are connected with the pivot pins. There is a over Centre lock point in toggle action and the over Centre lock point was a fixed stop and linkage. At a time in over Centre lock position, the clamp cannot unlock or move until the linkage is moved. All the toggle clamps work on same principle just their orientation are different.

Function of Toggle Clamp

The toggle clamp mechanism performs three major functions:

- Toggle mechanism increases load at handle into very high clamping force for the purpose of holding the work piece.

- Toggle mechanism provide over Centre lock for the prevention of clamp from releasing or opening the work piece unless the clamp is being opened by the operator.

- For rapidly closing and opening the clamp which provide maximum clearance for loading and unloading the work-piece.

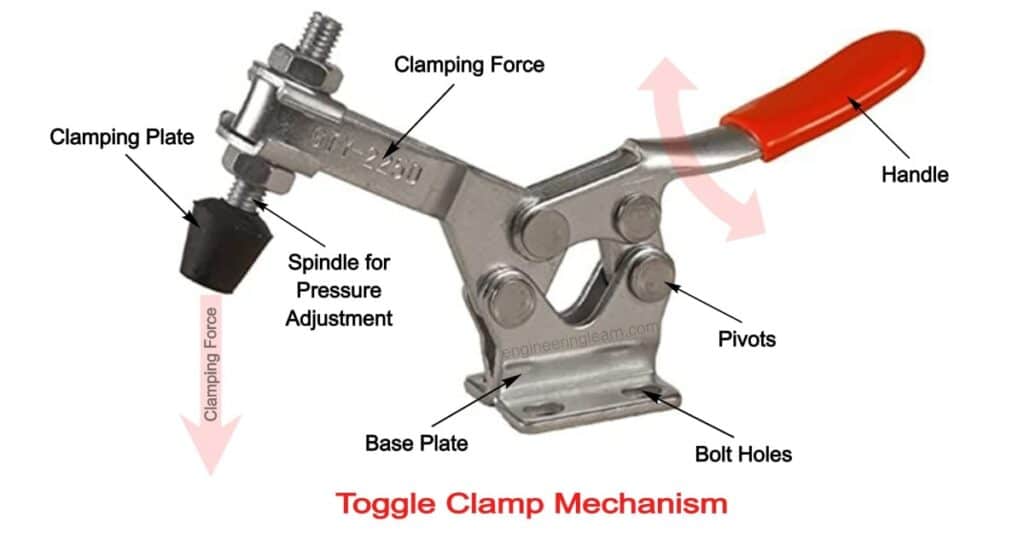

Parts of Toggle Clamp

1. Base

Base is the metallic body over which all the assembly is mounted. At the bottom of the base a hole is provided for mounting on worktable.

2. Linkages

They are generally used for getting huge mechanical advantages. They also keep a check on the quick clamping action. They release without any delay.

3. Clamping Arm

Forces are applied on work-piece with the help of clamping arm. Whenever the handle is operated, the clamping arm comes in contact with the surface of the work-piece and then holds the work-piece against the holding force.

4. Handle

Handles are operated by worker or operator and they oscillate about pivot or fulcrum.

5. Spindle

Spindle in toggle clamps are used for pressure adjustment.

Working of Toggle Clamp Mechanism

Toggle clamped mechanism are generally provided with linkage for locking their position by passing with the toggle point where force in linkage will result in maintaining its position. By passing with toggle point huge stress are applied to links.

In general, a generic toggle clamped mechanism should have four bar linkage, couple of traditional linkages and slider crank mechanism.

Element Details:

- A is the clamping member.

- C is the ground link.

- M is the coupler.

- N is the crank.

- P is the input link.

A is the output link which is used for holding the clamping jaw. Output link force available and output link velocity at output link clamps or holds work-piece, which is a function of link position, mechanism configuration, link length, actuator parameters and joint friction.

The force amplification ratio is an indispensable design parameter for toggle clamping mechanism. The successful execution of the toggle clamp depends upon the offered force at the site of clamping which is output link. Clamping force which is obtained at the output link is due to the geometric position of all links, input cylinder force as well as the coefficient of friction in between turning and moving parts.

The major target of designing of the toggle clamping mechanism is for producing maximum mechanical advantage while still keeping the cost less.

Important design parameters of toggle clamped mechanism are:

- Structural strength.

- Pin reaction at joints.

- Initial position of the links.

- Force magnification factor.

- Stroke and velocity of hydraulic cylinder.

- The velocity of the clamping or sliding member.

Types of Toggle Clamps

Various types of adjustable toggle clamps are:

1. Vertical Toggle Clamps

These toggle clamps are locked in the position at the time of handle is in vertical position.

2. Horizontal Toggle Clamps

These toggle clamps are locked in the position at the time of handle is in horizontal position, and they are not widely used.

3. Push Pull Toggle Clamps

In this toggle clamp, there is a plunger which travels in and out and results in providing pull and push forces. These toggle clamps can be locked in either pull or push position. Push pull clamps are also referred as straight line clamps or plunger style clamps.

4. Diagonal Hold Down Clamps

These toggle clamps are quite similar to the horizontal toggle clamp but they are in locked position when their handles are in diagonal position and they are not widely used.

5. Latch Type Toggle Clamps

These clamps use pull action for tightening. They are also known as pull clamps. They are best suited for locking, latching, fixtures or fastening doors. They are available in vertical as well as horizontal configurations. They can also require separate fixed catch.

6. Cam Clamps

These clamps are quite similar to the vertical clamps. The clamping force is generated with the action of roller on cam. The cam action enables components of various thicknesses to be clamped without any readjustment of the clamping spindle.

7. Hook Toggle Clamps

Hook clamps can pull two parts together which enable them for the applications like holding closed doors and closing doors, moulds, lids etc. they generally require separate fixed catch.

8. Pullback Clamp

The action of pullback clamps is similar to the plier clamp but it has a mounting body method.

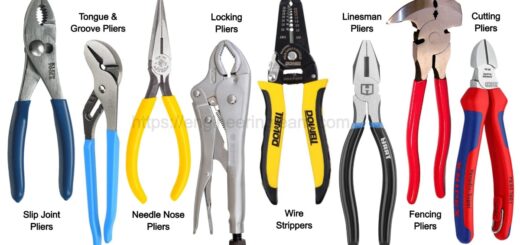

9. Plier Toggle Clamps

Plier toggle clamps are the handheld clamps which are configured same as a set of pliers. Squeeze action is required for closing, clamping. Plier toggle clamps are also known as squeeze clamps.

10. Toggle Edge Clamps

These toggle clamps can apply force in both downward and forward at same time.

Uses of Toggle Clamp

- Toggle clamped mechanism are used for multiplying hand force at handle when high clamping force is required to the hold work.

- Toggle clamped mechanism can create over centre lock for the prevention of opening as well as releasing of the work till it is opened by operator.

- Toggle clamped mechanism can rapidly close and open clamp. This provides wide clearance in which the work-piece can be loaded and unloaded.

Application of Toggle Clamp

- Toggle clamp mechanism is used for welding fixture.

- Toggle clamp mechanism is also used in electronic test fixtures.

- Toggle clamp mechanism can also be used as machine tool positioners.

- Toggle clamp mechanism serves for gauging fixtures and inspection.

- They are used in door assembly, woodworking jigs, door closure and latches for container lids.

Advantages of Toggle Clamp

- They are time saving and have quicker operations. The clamping and releasing in toggle clamp are done in seconds which results in time saving.

- Their setup is easy because no addition slotting, machining are required while using toggle clamp.

- There are different varieties of toggle clamps available in the market.

- They are highly durable because their components are zinc plated which provide enough corrosion resistance for longer duration.

- They require very less maintenance. They only require few drops of lubricating oil which keeps the toggle clamp in better working conditions.

- They are highly cost effective.