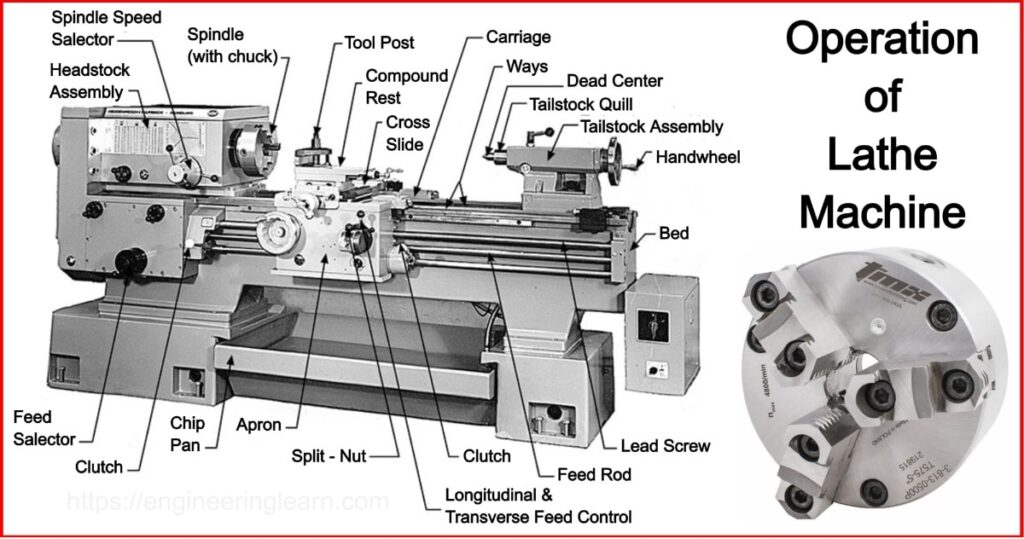

Operation of Lathe Machine

Operation of lathe machine :- lathe machine is used for shaping the workpiece by turning the parts with the help of rotating shaft to complete different operations likes deformation, drilling, cutting, knurling etc.

This machine works on the workpiece to create new objects with center axis. Operations that can be performed under this machine are of turning, facing, grooving, and parting off.

Types of Lathe Machine

Many Types of Lathe Machine;

- Engine lathe machine.

- Turret lathe.

- Special purpose lathe.

Components of the Lathe Machine

Mainly lathe machine consist of following components

1. Headstock :- Headstock present on the left way of lathe. It is in alignment with tailstock. The headstock is made up of cast iron.

2. Tailstock :- it is present on to the right side of the lathe machine. It provides the support to workpiece.

3. Bed :- it is the main part of lathe machine. All the parts of machine are bolted on the machine bed that mainly comprise of headstock, tailstock, carriage guideways and other parts. It is made up of cast iron.

4. Carriage:- it is situated between headstock and tailstock. It carry following parts as well like apron, saddle, compound rest, cross slide, and tool post.

While some other parts are listed below :-

Lead screw.

Feed rod.

Chip pan.

Hand wheel

Various Types of Operation

1. Turning

It is defined as the most usual operation performed in every lathe machine while turning is defined as the removal procedure of excess material from the workpiece/ job to produce a cylindrical surface of desired or required length.

Workpiece is to be placed between center and Spinning surface on the required pace. Lathe machine starts movements in longitudinal direction to move towards headstock that provides the better depth cutting.

2. Facing

Facing is the process of reducing of total length of workpiece by fed to the machine. The process of reducing the surface which is flat towards the endpoints of workpiece. This operation is performed by feeding the job piece perpendicular to the axis of rotation of the chuck. It is a operation that is done to produce the surface flat surface at the ends.

3. Knurling

It is a process of attaining diamond structure on the workpiece with high class perfect grip. Perfect grip is produced through the hand when surface is admitted to the machine. knurling machine is used for twisted task. Knurling machine relatively operate at low speed. Basically is is a process of sharp depression on the border of work surface.

4. Forming

Forming is the process in which convex, concave & any irregular surface to be formed on the workpiece with the help of forming tool. Forming tool equipped with the type of required shape for perform forming operation.

5. Reaming

The process of adjustment of the holes of the required accurate sizes is called Reaming. Reaming is always performed after the drilling operation. It is almost similar to drilling process

6. Undercutting

In this operation undercutting increase the diameter if process has been done internally and reduce the diameter if process done externally.

Application of lathe machine

- Lathe machine is used in metal working, wood turning, and metal spinning.

- Ornamental lathes can produce 3D solids of incredible complexity.

- It can be used as shape pottery, the potter wheel is latest well known design made by a lathe. ( Types of Metals )