22 Types of Screw Heads and Their Uses [with Pictures & Names]

![Types of Screw Heads and Their Uses [with Pictures]](https://engineeringlearn.com/wp-content/uploads/2021/08/Screw-Heads-1024x539.jpg)

Types of Screw Heads and Their Uses [with Pictures] :-

Types of Screw Heads

A) Countersunk Screw Heads

Countersinking method are used for preventing the split of wood when the wood is drilled. By the help of countersinking both proper angle as well as pilot hold are created which is required for housing the screw. In this process the holes are pre drill in addition with correct head angle which helps in creating finish look. Due to the angle and shape of some screw heads they need countersinking.

Various shapes of head which are required to countersink before they are drilled are:

1. Flat Head Screw: ( Types of Screw Heads )

Flat screw heads completely sit with the surface which leave no part of head exposed therefore these screws need to be countersink. The advantage of having flat screw head is that they do not stick out of the surface and leads catching other things on it. If the screw cover is used in this screw then the screw head are not visible.

2. Raised Head Screw: ( Types of Screw Heads )

Raised head are also known as oval shaped head, and they have angle which is similar to that of flat screw but they have dome shaped head. Countersink is required for these screws for accommodating the angle. As compared to flat screw their head slightly come out of the surface. This shape does not help in drive performance of the screw.

3. Bugle Head Screw: ( Types of Screw Heads )

These types of screw heads are commonly used for the screws which are made for drywall and plasterboard. The shape of these screws is similar to flat screw head but under the surface of head it has an angle which helps in reducing the damage to the surface. Drilling of pilot holes are not required because they are self-drilling. Stress is distributed over a wider area as compared to flat screws because of their unique shape.

B) Non Countersunk Screw Heads

These screws have head shape without having an angle. Various types of non-countersink screw heads commonly used are:

1. Binding Head Screw: ( Types of Screw Heads )

They are a unique screw which are used for various of projects. They have domed head and can screw in each other. Short binding screws are used for holding large manuals as well as book binding projects. They are also used for holding leather, swatches together.

2. Dome Head Screws: ( Types of Screw Heads )

Domed head screws are very common type of screw. They are best suited for the work in which head of the screw are not hidden like flat head screws. The dome shape head provide appealing design to the surface and the flat part behind the dome helps in stopping the screw where it is to be stopped.

3. Flange Head Screws: ( Types of Screw Heads )

Flange screws are also known as frame screws. The head of the flange screws can be circular to hexed and are extended out from circular flange situated directly below the head. The flange at the head provide stability to the screw for remaining in the position and take the position of washer.

4. Truss Head Screws: ( Types of Screw Heads )

In comparison to the other screw head truss screw head are wider and they have a rounded surface. Truss head screws are used for sheet metal or for the work where there is the requirement of large holes and the wider head of the screw prevent them from going into the hole.

C) Combination Head Screws

Combination head screws are very common nowadays, they have variation and combination of above given head types.

A countersink screw heads have angular shape under the head but the screw in which countersink is not required have flat under the head.

D) Tamper Resistant Screws

These screws are variations of few common types of screws like hex, Phillips. They are best suited for public places where the chances of theft are high such as public restrooms. Following are the types of tamper resistant screws in which there are multiple levels of security:

1. Pin Head Screws: ( Types of Screw Heads )

Pin screws are one of the most common tamper resistant screw, they have same design like a cross shape in Philips screw having additional layer which is provided for the prevention of easy removal. In design there is additional pin in each head and they need special tool for removal and installation. For the removal and installation of a tamper resistant Philips screw, Philips screwdriver cannot be used.

2. Sentinel Screw Head: ( Types of Screw Heads )

These screws provide very high level of protection because they can be driven only in one way. They are very difficult to remove therefore they are best suited for permanent fixtures.

3. 2 Hole Screws: ( Types of Screw Heads )

They are also called as spanners; they provide security with maintaining the finished look. Their heads are flat in which there are two small holes are provided and they need special tool for their installation as well as removal.

E) Screw Head Drive Type Screws

In this category there are some screws which require specific type of screwdriver for their installation.

1. External Hex Screw: ( Types of Screw Heads )

They have hexagonal shape at head which extend beyond its surface. Some of them have built in flange while other have hexagon shape over their full head. This screw can be removed and installed with the help of a wrench.

2. Internal Hex Screw: ( Types of Screw Heads )

These type of screw always need an Allen wrench for their installation as well as their removal. They are generally used for furniture which need assembly and cannot get damage by Allen wrench at the time of installation which results in pleasing finish. Most of these screws come with Allen wrench.

3. Phillips Head Screw: ( Types of Screw Heads )

They are most common screw among all. They have cross shape which helps in self centering the screw which avoid the drilling in odd angles. A drill can also be used with this screw and due to their self-centered design, they remain at their place at the time of drill when the force is being applied but head can be strip if too much force is applied.

4. Pozidriv Head Screw: ( Types of Screw Heads )

These screws are somewhat similar to Phillips screws but posidriv screws have more grooves which results the shape of posidriv screws resembling a star. For their removal sometime Phillips screwdriver can also be used. They provide more stability to the applied force as compared to the Phillips screws. The difference between a Phillips screw and a posidriv can be identified by looking them from side. There are ribs between all the four arms of the posidriv and are marked by ‘pz’.

5. Quadrex Head Screw: ( Types of Screw Heads )

These head drive are also called as Phillips square drive and they are the combination of square recess and Phillips. Quadrex head drive looks like Philips design but middle of cross shape are squared instead of pointed which prevent stripping when more force is being applied.

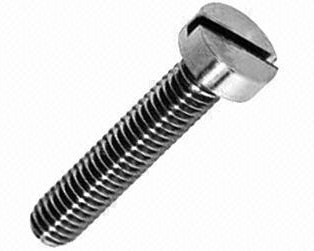

6. Slotted Head Screw: ( Types of Screw Heads )

These are the screws which are generally referred as the flat head screws due to the narrow opening provided for flat screw driver. These screws are most commonly used and are cheap among others. But the main disadvantage of using this screw is that they are very much likely to be stripped. Even the design of this screw is such that they strip for the prevention of over tightening of the screw. They are best suited for the projects which needs a smaller number of screws which can be screw manually instead of using powered drill which can results the screw to strip.

7. Square Recess Screw: ( Types of Screw Heads )

These screws are generally known as Robertson’s. They have square center point which prevent them from stripping out.

8. Star Head Screw: ( Types of Screw Heads )

These screws encompass various different styles which form the shape of stars. There is a double square drive which have two robertson’s squares which create 8-point star in middle.

There is a triple square drive which have three robertson’s squares which form 12-point star. Triple squares are generally used for resisting high force and no stripping of the screw commonly used in internal parts of the car such as drivetrain components.

9. Torx Screw Head: ( Types of Screw Heads )

In the middle of these screws they have 6 point star shape and they are generally used for electronics items such as DVD players and computers. These screws are getting popular nowadays due to their ability to resist the slip out tendency which are very important criteria while building electronics.

10. Torx Plus Screws: ( Types of Screw Heads )

These screws have smaller grooves which enable the screw driver to have more contact with screw head which allow us to apply more force on it.

11. Tri Wing Screw Head: ( Types of Screw Heads )

These screws are recently invented by the Phillips screw company. These screws provide more security in compared to all other screws and can sustain more force. They require special driver for their installation and removal and the deep grooves in it enable them for more torque from drill.