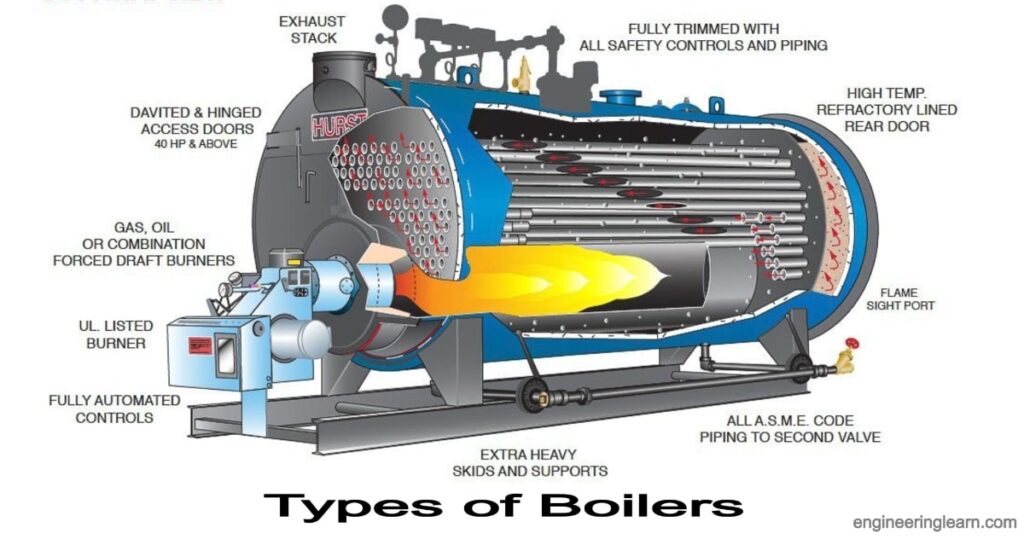

16 Types of Boilers – Definition, Parts, Uses, Working, Application, Advantages & Disadvantages [Complete Guide]

What is a Boiler?

Types of Boilers: Definition, Parts, Uses, Working, Application, Advantages & Disadvantages :- A boiler is a type of closed vessel which converts fluid into high pressure vapor by heating to generate power. The boiler converts the energy taken from fuel such as coal, nuclear fuel and natural gas to convert water into steam.

Boilers are closed vessel which is used for heating water or other liquid and then vapour or steam are generated, steam are super heated or may be of any combination under vacuum or pressure for using them by the application of their energy from combustion of fuel from nuclear or electrical energy.The vaporised or heated fluid in the boiler are used for various of applications or process like water heating, boiler based power generation, sanitation cooking etc.

Boilers are pressure vessel which is generally made up of steel. Due to corrosion and stress corrosion cracking, stainless steel of austenitic types is not uses in the wetted part of the boilers. Generally ferritic stainless steel is used for superheated sections which are not exposed to the boiling water.

Working Principle of a Boiler

The working principle of a boiler is same as the water is in a closed vessel due to which it converts into the steam. The converted steam possesses high pressure kinetic energy. The water contained in a boiler is converted into steam due to the heat which is generated by burning of fuels like coal, nuclear fuel, etc. The high pressure steam passes through the tubes and exits from the boiler into the turbine which rotates the turbine along with the generator to produce electricity.

Parts of Boilers

Following are the main parts of boiler:

1. Heat Exchanger

Heat exchanger are that components which are used for transferring the heat which is produced by burners in combustion chamber to the boiler. Heat exchangers are made up of several of elements like bundles of steel tubes, copper lines or cast iron. The heat exchanger element should be such that they can withstand with high temperatures, efficiently transfer heat and last a long time.

2. Controls

System controls enable user to set the temperature of water, fuel and air supply mixtures, ignition and internal pressure. They can regulate the frequency of burner fires, rate at which fuel used quality of mixture of oxygen and fuel. They plays an important role in safety system of boiler. They reduce the risk of damage to a higher extent.

High pressure, uncontrolled steam are highly dangerous and they need to be maintained well by the system control for keeping the boiler safe by ensuring that the internal pressure should be in limits, water should be within safe temperature range.Pressure control device: Pressure control device are used to control the boiler pressure without which an operator is required for manually adjust boiler firing rate for maintaining system pressure and without lifting the safety valve or tripping the boiler.

High temperature or high pressure cut out switch: It is a simple temperature switch or pressure switch (temperature switch for hot water boilers and pressure switch for steam boilers) which is used to put the boiler out of commission.

3. Burner

The burner are that part of a boiler where fuel source mixes with air and combusts, then hot combustion gases enter the boiler and serves as heat exchanger. The correct amount of combustion air is necessary for efficient and clean combustion therefore burner should be kept in good working condition. Less amount of air do not allow complete combustion while huge amount of air will results in loss of exhaust gases.

4. Combustion Chamber

In combustion chamber fuel is burned for heating the water. The combustion chamber has burners and is designed for providing safe area for high temperature combustion of volatile fuel. Combustion chamber is generally made up of cast iron or steel or metal which can cope with high temperatures. Combustion chamber need to be serviced on regular basis because older units can crack or corroded which is unsafe for use.

5. Exhaust Stack

Exhaust stack are also known as flue or chimney and are designed for safely expel spent fuel away from the exterior of building. They look like a brick built chimney or may be series of metal pipes. They must be constructed such that harmful gases like carbon monoxide divert away and do not expel near doors and windows.

6. Supply Lines & Return Lines

They lead from boiler and they deliver steam or heated water at the distribution points like radiators or heaters. When steams and waters cools then return lines brought water back to boiler and there water is again heated before sent out again.

7. Circulator Pump

Circulator pumps are that component of boilers which pushes hot water out via supply lines to the distribution lines or the radiators. Circulator pumps are responsible for bring it back via return lines. Circulator pumps are very essential component for the boiler therefore they should be well maintained.

8. Backflow Valve

Backflow valve are used as a safety unit and they allow the fluid flow only in single direction.

9. Expansion Tank

It is a small tank which protect boiler from excess pressure and checks its safety with the process.

10. Aquastats

Aquastats in boiler are used for sending correct signal to burner about when to start or stop the process. According to the temperature of fluid present in boiler they know when to start or stop the process.

11. Auxiliary & Primary Low Water Cut off Switches

These devices are used to determine the low water conditions in boiler whenever these condition arises they used to initiate master fuel trip for shutting the burner off. If they are cleaned thoroughly on annual basis then they have 10 years of expected life but if the maintenance is neglected then they need to be replaced very quickly.

12. Firebox

Firebox are that part of boiler where fuel meets the air and create flame.

13. Refractory

Refractory are those materials which are used for filling any openings or gaps around the fire box which helps the fire to stay in fire box.

14. Condenser/ Deaerators

Condenser and deaerators tanks are generally used in steam boiler systems only instead of hot oil and hot water boiler because the fluids are always in the liquid state.

15. Low and High Gas Pressure Switches

These pressure switches are essential for ensuring the gas pressure in the boiler. These switches in the boiler prevent the boiler to go lean or rich with the gases which can result in explosion or major damage.

16. Water Level Device

Various boilers feed water control system uses different devices for controlling the level of water in the boiler. From simple on off setup which is run by a switch, level sensing devices are connected with the loop controller. When a boiler is run without feed water controls then it requires a operator for full time to adjust the manual valve.

Different Types of Boilers

A) Based on the Contents in the Tubes

Fire Tube Boiler

Water Tube Boiler

B) Based on the Number of Tubes

Single Tube Boilers

Multi tubular Boiler

C) Based on the Position of the Furnace

Internally Fired Boilers

Externally Fired Boilers

D) Based on the Axis of the Shell

Vertical Boilers

Horizontal Boilers

E) Based on the Methods of Circulation of Water and Steam

Natural Circulation Boilers

Forced Circulation Boilers

F) Based on features.

Cochran boiler

Lamont boiler

Loeffler boiler

Babcock and Wilcox boiler

Lancashire boiler

Locomotive boiler

A) Based on the Contents in the Tube

1. Fire Tube Boiler: ( Types of Boilers )

The fire tube boilers are the types of boilers in which hit gases produced from heat source flows through pipes with water filled drum. In this type of boiler, the amount of water present in the boiler is much higher than the hot gases presented in the tubes. The heat transfers from the hot gas tubes into the water present around the hot gas tubes and converts it into steam. The fire tube boilers are used for steam locomotive boiler. They are easy to operate and simple in construction. Types of fire tube boilers-

- Cornish fire tube boiler

- Lancashire fire tube boiler

- Locomotive fire tube boiler

- Vertical fire tube boiler

- Cochran fire tube boiler

- Scotch marine fire tube boiler

- Immersion fire tube boiler

Advantages of Fire Tube Boiler

- They have low maintenance cost.

- They are simple in design.

- Less skilled operators are required to perform operations.

- Feed water treatment is not necessary for fire tube boiler.

- Pure feed water is not required to operate fire tube boiler which reduces the cost.

- To produce same power output, fire tube boiler is less costly than water tube

Disadvantages of Fire Tube Boiler

- The limit of operating pressure in fire tube boiler is up to 20 bars.

- The efficiency is up to 70%.

- More area is required for a given output.

- The quality of steam is not better in comparison of water tub e boiler.

- Used in small plants.

2. Water Tube Boiler: ( Types of Boilers )

A water tube boiler is a high-pressure boiler in which water circulates in the tube heated by the fire or hot gases present in the drum surrounds these tubes. In this type of boiler, fuel burns inside the furnace, creating the hot gases which convert water into high pressure steam. The steam exits from the steam drum in which steam water mixture accumulates. In some cases, the steam passes through the tubes becomes superheated which means water tube boiler can produce both saturated or superheated steam. These types of boilers used in chemical, process, refining, paper manufacturing and pulp industries. Types of water tube boiler-

- Simple vertical boiler

- Stirling boiler

- Babcock and Wilcox boilers

Advantages of Water Tube Boiler

- The water tube boiler can operate at maximum working pressure of 250 bar.

- It has an overall efficiency is up to 90% with an economizer.

- Less area is required for a given output.

- Fluctuation of load can be easily handled.

- It has higher steam generation and the quality of steam which is suitable for efficient power generation.

- Used in large plants.

- Water circulation is in well-defined direction.

Disadvantages of Water Tube Boiler

- It has ahigh maintenance cost and complex design.

- A skilled operator is needed for operation.

- Used in large power plants because it is uneconomical in small industries.

- Treatment of feed water is very necessary in a water tube boiler as small-scale deposits present inside the tube can become the cause of overheating and bursting.

B) Based on the Number of Tubes

1. Single Tube Boiler: ( Types of Boilers )

This type of boiler contains only one fire tubes or water tubes. Types of single tube boilers-

- Cornish boiler

- Simple vertical boiler

2. Multi Tubular Boiler: ( Types of Boilers )

This type of boiler contains two or more water tubes or fire tubes. Types of multitubular boiler-

- Lancashire boiler

- Locomotive boiler

- Cochran boiler

- Babcock and Wilcox boiler

C) Based on the Position of the Furnace

1. Internally Fired Boiler: ( Types of Boilers )

In this type of boiler furnace is located inside the boiler drum which means furnace is a part of boiler structures. Types of internally fired boilers-

- Lancashire boiler

- Cochran boiler

- Locomotive boiler

2. Externally Fired Boiler: ( Types of Boilers )

In this type of boiler, the furnace is located outside the boiler drum which means furnace is not a part of boiler structure. Types of externally fired boilers-

- Stirling boiler

- Babcock and Wilcox boiler

D) Based on the Axis of the Shell

1. Vertical Boiler: ( Types of Boilers )

These are a type of fire tube or water tube boiler in which the axis of the boiler barrel is oriented vertically. They are used in railway locomotives, road vehicles, steam tractor,etc. Types of vertical boiler

- Cochran boiler.

Advantages of Vertical Boiler

- It has low initial cost because of fewer parts.

- It has low maintenance cost.

- Simple in working

- Easy to install and replace.

- It requires small area on the ground.

- They have water level tolerance.

Disadvantages of Vertical Boiler

- Its vertical design limits its work in many cases.

- It produces limited steam due to limited area.

- The impurities present in this type of boiler settle at the bottom and prevents heating.

- The boiler tubes are small.

2. Horizontal Boiler: ( Types of Boilers )

These are a type of fire tube or water tube boiler in which the axis of the boiler barrel is oriented horizontally. Types of horizontal boilers-

- Lancashire boiler

- Locomotive boiler

- Babcock boiler and Wilcox boiler

E) Based on the Method of Circulation of Water and Steam

1. Natural Circulation Boiler: ( Types of Boilers )

In this type of boiler, the water circulation takes place naturally by convection currents which develops during the heating of water. The convection current develops due to difference in density caused by temperature of water. Types of natural circulation boilers-

- Babcock and Wilcox boiler

- Lancashire boiler

2. Forced Circulation Boiler: ( Types of Boilers )

In this type of boiler, the circulation is done with the help of boiler driven by the external power. Types of forced circulation boiler-

- Velox boiler

- Lamont boiler

- Loffler boiler

F) Based on the Construction

1. Cochran Boiler: ( Types of Boilers )

Cochran Boiler is a type of multi tubular vertical fire tube boiler which has a number of horizontal tubes. It is the modified form of a simple vertical boiler where the heating surface is increased by means of a number of fire tubes. The efficiency of this boiler is much better in comparison of the simple vertical boiler.

Advantages of Cochran Boiler

- Installation cost is low

- Less floor area is required.

- Easy to operate and handle.

- It is easy to transport Cochran boiler.

- All types of fuels are usable.

Disadvantages of Cochran Boiler

- It has low rate of steam generation.

- It is difficult to inspect and maintain.

- Pressure range is limited.

2. Lamont Boiler: ( Types of Boilers )

It is a type of high-pressure water tube which is based on forced circulation in which water circulation takes place through an external pump through long closely spaced small diameter tubes. In this, the pump is employed in order to have adequate and positive circulation in steam and hot water boilers.

Advantages of Lamont Boiler

- High pressure boiler.

- Flexible in design.

- It can be reassembled into natural circulation boiler.

- Easy to start.

- It has high steam generation capacity near about 50 tons per hour.

- Higher heat transfer rate.

Disadvantages of Lamont Boiler

- Bubble formation takes place at surfaces of the tubes which reduces the heat transfer rate to the steam.

3. Loeffler Boiler: ( Types of Boilers )

It is a type of water tube boiler which has a high-pressure steam generation capacity.

Advantages of Loeffler Boiler

- It has a compact size

- It does not produce much sound.

- Salt sediment does not deposit at surfaces.

Disadvantages of Loeffler Boiler

- Evaporating drum id bulky and costly.

- Bubble formation takes place which creates a problem of heat transfer.

4. Babcock and Wilcox Boiler: ( Types of Boilers )

It is a type of horizontal water tube boiler which is also known as longitudinal boiler.

Advantages of Babcock and Wilcox Boiler

- Higher steam generation capacity.

- Easy to repair defects.

- It occupies less area.

- Minimum draught loss inside the furnace.

- Easy to inspect during operating condition.

Disadvantages of Babcock and Wilcox Boiler

- High maintenance cost.

- Small scale impurities of water may deposit at the surface which leads to overheating and bursting of tubes.

5. Lancashire Boiler: ( Types of Boilers )

It is a horizontal and stationary type of fire tube boiler which is internally fired. It works on the basis of the natural circulation.

Advantages of Lancashire Boiler

- High thermal efficiency.

- Easy to operate.

- Easily meets the load requirement.

- Easy to maintain.

- Consumption of electricity is low due to natural circulation.

Disadvantages of Lancashire Boiler

- Produces low pressure steam.

- Grate are aid limited.

- Low steam production rate.

- It requires more floor space.

6. Locomotive Boiler: ( Types of Boilers )

A locomotive boiler is used to create steam from water by with the help of heat energy. It is a multi-tubular, horizontal drum axis, natural circulation, forced circulation, artificial draft, medium pressure, solid fuel fired fire tube boiler which has an internal fire furnace.

Advantages of Locomotive Boiler

- It is a portable boiler.

- It can handle sudden and demand of fluctuating loads.

- Cost effective.

- High steam generation rate.

- Compact in size.

Disadvantages of Locomotive Boiler

- Corrosion and scale formation takes place.

- Unable to handle heavy load conditions.

Image Source :- marinersgalaxy