Types of Furnace and How They Work in Homes & Industries [Explained in Detail]

What is Furnace?

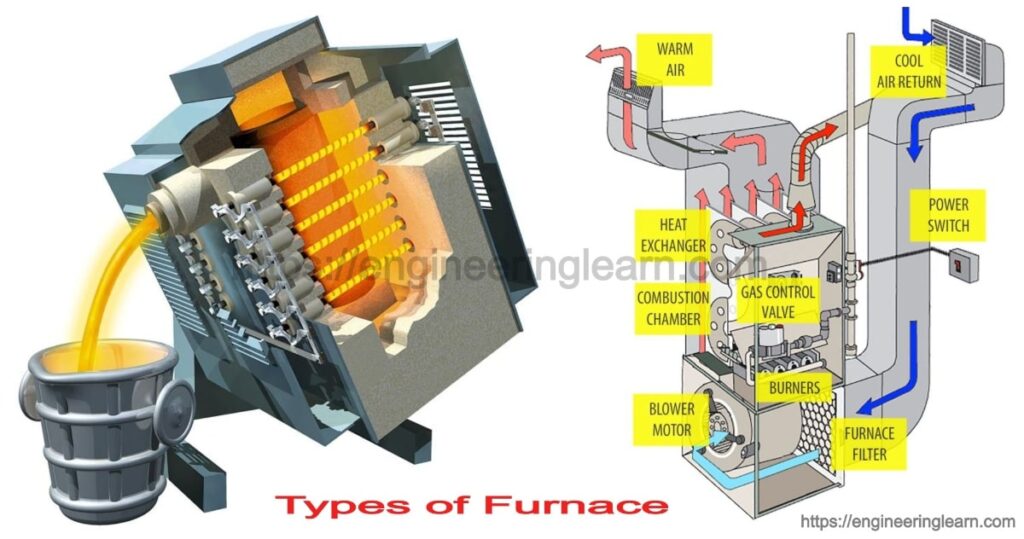

Types of Furnace and How They Work in Homes & Industries :- Furnaces are referred to as those devices which are found to generate the heat in a controlled manner through the combustion of a fuel source. The thermal energy is found to be used to heat the spaces like the rooms, buildings or other structures. Other furnaces can be used in commercial as well as industrial settings in order to process the materials.

Different Types of Furnace

This articles aims to make you learn about the different types of furnaces will can be explored, summarized mainly under these two broad classifications:

- Types of Industrial Furnaces

- Types of Furnace for Heating Homes and Buildings

A) Types of Industrial Furnaces

Furnaces in the industrial settings are found to heat up the materials by using fuel and combustion gases. These materials may be in direct contact with the fuel and its gases like blast furnaces or in indirect contact with the fuel but still in direct contact with the gases or indirect contact with both fuel and gases. In all the cases the goal remains the same which is to attain a higher level of heat.

One of the primary consideration while selecting an industrial furnace is typically considered as the range of operating temperatures which the furnace can provide. Furnaces which reach higher temperatures are found to cost more. The main aim of an industrial furnace is the temperature efficiency uniformly.

Some of the most common types of furnaces are those which are used for metals and materials processing and are mentioned below:

- Bell Furnaces

- Box Furnaces

- Forging Furnaces

- Pit Furnaces

- Salt bath Furnaces

- Tempering Furnaces

- Vacuum Furnaces

1. Bell Furnace: ( Types of Furnace )

Bell furnaces are usually those which are electrically heated, gas-fired or thermal recirculation heating system which features a movable dome. This furnace hood can be lifted frequently throughout the vacuum or can also be controlled through the atmosphere processes.

Bell furnaces are used to temper, anneal, normalize and stress relieve the steel plate formed parts. This equipment is mostly used with multiple bases and is still found to provide reliable seals. These furnaces either multi or single stack are used to treat the coils, strips, sheets, rods and more.

2. Box Furnace: ( Types of Furnace )

Box furnaces are the ones which are usually used for heat-treating, calcination, curing, preheating, tempering and other processes. The box furnaces feature vertical lift or swing open doors which insulates the furnace and ensures consistent airflow management.

Box furnaces are also referred to as the ones which accept heavy loads and are set up to be loaded through roller hearth, or any other manual process. There are various gas and electric versions available in the market which are able to uniformly treat large material volumes due to which the box furnaces are seen in most of the laboratories and industrial applications.

3. Forging Furnace: ( Types of Furnace )

Forging furnaces are referred to as the ones which are mostly used for the purpose of pre-heating, slot forging furnaces which quite resembles to a pizza oven. These open-hearth furnaces are those which transmits the heat via radiation in order to get metals to a temperature at which they can be forged or to also stop the hardening processes.

Heavy duty forging furnaces usually either heat or reheat large steel ingots, blooms and parts. These furnaces are found to come in Forging Box style. The type of load charge and discharge can be automated in some of these furnaces.

4. Pit Furnace: ( Types of Furnace )

Pit furnaces are referred to as those furnaces which are available in gas-fired or electric-powered configuration. These furnaces are also referred to as the top load furnaces which is Offered in many sizes. The pit furnaces heats to various temperatures within a secured working chamber along with a controlled atmosphere. These furnaces are mostly used in automotive and aircraft part by manufacturing as well as machine building, wind energy and mining.

5. Salt Bath Furnace: ( Types of Furnace )

Salt bath furnaces are referred to as those furnaces which use the high-heat transfer characteristics of convection in order to achieve the fast heating of metal parts in heat treating applications, like almost 5X the rate of air furnaces. These furnaces are mostly invariably electric as the electrodes can be immersed directly in the molten salt, whereas externally the heated electric or gas-fired units are sometimes used. The temperature of the bath varies depending on the varieties of salts which has been used, most commonly cyanide mixtures and chloride mixtures, with temperatures varying from 300-2350°F.

Salt baths furnaces are those furnaces which are used for treating high-speed tool steel and other edge tools, annealing nickel-chrome alloys and stainless steel, austempering and martempering steel, etc.

Also for brazing else there is a difficulty to braze parts like automotive radiators or for setting the shape of shape-memory alloys. It is found to surround any part along with a non-oxidizing atmosphere while the immersion takes place and also coats it with a layer of salt that protects it during transfer of the quench.

Salt bath furnaces are typically those which uses ceramic or metal pots that depends on the temperature at which they are found being operated. The electrodes are usually mild or high chromium steel which depends on the requirement of temperature, and are typically square-edged as compared to round in order to maximize magnetic flux. The electrodes are usually controlled through a tap changing transformer so that the power to them can be adjusted as they wear.

6. Tempering Furnace: ( Types of Furnace )

Tempering furnaces are referred to as those furnaces which are specifically designed in order to heat the ferrous metal products which is responsible for increasing the toughness. Heat treating high strength materials are the ones which can impact the alloy’s formation and energy absorption.

In order to access the best balance of strength and elasticity, the tempering furnaces are usually used in conjunction with the quenching furnaces. It is quite crucial that these furnaces are found to maintain a uniform temperature levels throughout the chamber in order to achieve the desired material characteristics. Both the gas as well as electric heating types of these furnaces are the ones which offer indirect fuel contact.

7. Vacuum Furnace: ( Types of Furnace )

Vacuum furnaces are referred to as those which are mainly used in various industries. The type of furnace is the vacuum which is maintained throughout the heating process in order to protect the heated steel and the metal parts. The furnace can be either electric or gas heated with pumps which would preserve the vacuum in order to prevent the oxidation, heat loss, or contamination. These furnaces are preferred for annealing, brazing, sintering and heat treatment.

B) Types of Furnace for Heating Homes and Buildings

Furnaces are usually the devices which are found to provide heat to homes and other buildings by blowing heated air through the ducts that deliver warmth to different rooms. The heat energy that fuels a furnace can be generated via fuel combustion, electricity and other means.

The things to consider includes the cost of the furnace itself, the cost of the fuel used, venting requirements and the Annual Fuel Utilization Efficiency (AFUE), which is found indicating the efficiency of the furnace’s combustion. Scrolling down one can explore different types of furnaces which is classified by the fuel or method by which the heat energy is generated:

- Oil fired Furnace

- Gas Fired Furnace

- Duel fuel Furnace

- Waste Oil Furnace

- Electric Furnace

- Wood burning Furnace

1. Oil Fired Furnace: ( Types of Furnace )

Mostly all the new oil-fired furnaces are found to have AFUE ratings of 80 to 90 percent and are popular in the areas with limited access to the natural gas. With an approximate lifespan of 30 years, oil furnaces tend to be less expensive as compared to the gas furnaces, whereas oil is more expensive than gas and the prices can be volatile.

The oil furnaces are found to require an on-site storage tank for the purpose of maintenance, oil-fired furnaces are found to develop the deposits of soot and carbon on the heat exchanger surfaces which mostly require a periodic removal in order to maintain the efficiency. In addition to this, the nozzle on the burner unit can be in a need of replacement as well as the oil filters used to remove the impurities.

2. Gas Fired Furnace: ( Types of Furnace )

Gas-fired furnaces are known to be those furnaces which are highly used for the domestic applications, making gas the most commonly-used heating fuel. While the gas furnaces are found to be quite expensive as compared to the oil furnaces, paying for the installation of a municipal gas line may add to the costs. Now the latest gas furnaces are found having an AFUE rating of 89 to 98 percent.

Gas is the cleanest burning of non-renewable energy options which carries the danger of carbon monoxide leaks, making it mandatory to install the carbon monoxide detectors. The Gas furnaces are found having a lifespan of up to 25 years which are easier to maintain as compared to the oil furnaces as they tend to stay clean despite its usage.

3. Dual Fuel Furnace: ( Types of Furnace )

Dual fuel furnaces are referred to as those furnaces which use a heat pump for some specific cool weather and gas furnace for more cold weather. Heat pumps are simply found to remove heat from the outdoors and deposit it in your home. Inside the heat pump, an air handler is installed which is responsible for warming the air as it passes over a coil of hot refrigerant, then a fan blows the warm air into the area.

The heat pumps are found to be an inefficient way of maintaining a comfortable temperature during the colder months whereas dual fuel systems switches to gas heating when it gets cold and then back to the heat pump in the warm weather. This is considered as one of the most efficient system in the market in terms of energy uses and associated costs, whereas the initial installation or upgrading of a system can be expensive.

4. Waste Oil Furnace: ( Types of Furnace )

Waste oil furnaces are referred to as those furnaces which mostly burn the oil which can no longer be used for its intended purpose, like automotive or vegetable oil. These furnaces are mostly promoted as a green or environmentally friendly solution as they are the recycling oil that would otherwise have to be disposed of.

The waste oil can contain all the lubricants, detergents and more, including the pollutants like lead, PCBs and chromium which becomes airborne during heating. The waste oil furnaces can last mostly up to 20 to 25 years, with regularly cleaned furnaces working with higher efficiency.

5. Electric Furnace: ( Types of Furnace )

As the running cost of the electric furnaces is considered to be higher than options like gas and oil furnaces, they are not found having the same benefits. Electricity is usually available all over the place where these furnaces are to be installed including the areas where gas or oil is more difficult to source. Electric furnaces if connected to solar panels can be a source of renewable energy, along with the associated savings.

It is commonly found that all the electric furnaces have an AFUE of 95 to 100 percent which means higher running costs can potentially be recouped through the efficiency. The electric furnaces are considered to be safer than gas and oil options as they do not possess danger of gas leakage and no actual fire present in the furnace.

6. Wood Burning Furnace: ( Types of Furnace )

Wood-burning furnaces are referred to as those furnaces which are a viable option for heating homes in the areas where firewood is plentiful and affordable. Wood is usually burned in a firebox and is then circulated through the ductwork in the same manner which is used in oil and gas furnaces.

Wood burning furnaces are usually fueled manually and the fire has to be tended, which means that these are impractical if you want the house to be heated while you are not present for an extended period. This is why wood furnaces are a part of combination furnace where an oil or gas burner functions as a backup heat source. Conventional wood-burning furnaces may have an AFUE as low as 45 to 55 percent whereas the state of the art models can reach from 75 to 90 percent.

Image Source :- dormarhvac, kanthal