7 Types of Sandpaper for Wood & Metal – Selecting the Correct Coarseness [Explained with Details]

![7 Types of Sandpaper for Wood & Metal - Selecting the Correct Coarseness [Explained with Details]](https://engineeringlearn.com/wp-content/uploads/2022/01/Sandpaper-1024x539.jpg)

Introduction of Sandpaper

7 Types of Sandpaper for Wood & Metal – Selecting the Correct Coarseness [Explained with Details] :- Sandpaper is a critical instrument for giving wooden or different surfaces a smooth completion. There are found to be various types of sandpapers which seem to be quite comparative yet are still found being made out of various materials and are intended for sanding various types of surfaces. This guide audits the different kinds of sandpaper and how such factors as coarseness and material show the best sandpaper for your undertaking.

The sandpaper sheets are referred to as those sheets which are found containing no sand in them. Sand has been supplanted by more powerful regular abrasives, like garnet, and engineered abrasives, like aluminum oxide. The various kinds of sandpaper have three essential qualities: its coarseness, its rough material and an open or shut coat.

The coarseness of sandpaper is measured in grits. The grit number on a piece of sandpaper relates to the number of holes per square inch in the screens used to sieve the grains during the manufacturing process.

The grit level is found ranging from a level of 12 to 600. For most of the home sanding operations the grit size can vary from 60 to 220 which is usually very commonly recommended by every technician.

The density of abrasive particles on a piece of sandpaper is indicated by coating. Abrasive granules cover around 70% of the surface of open-coated sandpaper. This is especially useful with power tools and soft timbers like pine. These are most commonly found having their applications for the better hand sanding or for working along with the hardwoods as well as various other metal surfaces.

Material of Sandpaper

The materials which are commonly found being used in order to make sandpaper are found including aluminum oxide, ceramic, flint, garnet and silicon carbide.

Well being: Sanding produces dust, so wear defensive eye wear and a respirator veil. When working with a power sander, wear gloves and stay away from baggy attire that can get found out in the machine.

Types of Sandpaper

1. Aluminum Oxide Sandpaper: ( Types of Sandpaper )

Aluminum oxide sandpaper is a manufactured material that is either tan, light dark or greyish brown. Its main function is to provide a wide range of sanding, particularly wood and metals. It is compelling when utilized with a power sander. Its weak surface disintegrates effectively, uncovering new edges for sanding wood and making it last longer than different sandpapers.

2. Ceramic Sandpaper: ( Types of Sandpaper )

Before sanding wood, an individual folds a piece of ceramic sandpaper. Ceramic sandpaper is made of a reddish-brown synthetic substance. It’s tough and long-lasting, making it ideal for rigorous sanding. It’s great for sanding with power tools. It’s possible that it’ll cost more than other sandpapers.

3. Garnet and Flint Sandpaper: ( Types of Sandpaper )

Garnet and rock sandpapers are produced using regular material. Garnet sandpaper is rosy or brilliant brown and stone sandpaper is beige-shaded. Garnet sandpaper includes a delicate coarseness and destroys the quickest yet delivers the smoothest surface. Rock sandpaper is affordable however not especially sturdy. Rock is referred to as one of the best material for the purpose of harsh work on the little activities and is also found being utilized for the less usually than the numerous different sandpapers.

4. Silicon Carbide Sandpaper: ( Types of Sandpaper )

On a metal surface, silicon carbide sandpaper is utilised. Silicon carbide sandpaper is a blue-grey, black, or charcoal synthetic paper with a waterproof backing. These are the ones which are commonly found to work on both the wet as well as dry surfaces.

On harder materials, its friable surface will self-sharpen, making it the perfect sandpaper for metal and plastic. It’s great for polishing or using in between finish layers.

5. Steel Wool: ( Types of Sandpaper )

Among the other rough items, steel fleece comprises of fine adaptable fibers of steel or different metals. It is utilized for completing the process of, cleaning or eliminating grime and ooze from an assortment of surfaces.

Steel wool is referred to as the one which can be utilized in order to eliminate the rusted coatings of the paint or finish on wood, glass, tile and furniture. Steel fleece or wool is the one which is found being responsible to give finishing as a new surface or either like painted or to get done by being utilizing within the coats.

It is reviewed on a numeric scale like sandpaper that decides how coarse or fine it is, appraised from 0000# (very fine) to 4# (exceptionally coarse).

6. Drywall Sanding Sheets and Screens: ( Types of Sandpaper )

A drywall sanding pad and an extension pole are used. A sandpaper like the material of a drywall sanding pads, sheets or screens, are found being designed in an abrasive material which are perfect for fulfilling the regular sanding applications.

These types of sanding sheets are ideal as drywall joints, plasters as well as compounds used for patch work. Most drywall sanding tools, including hand extended pole sanders for hard-to-reach regions, can attach to drywall sheets.

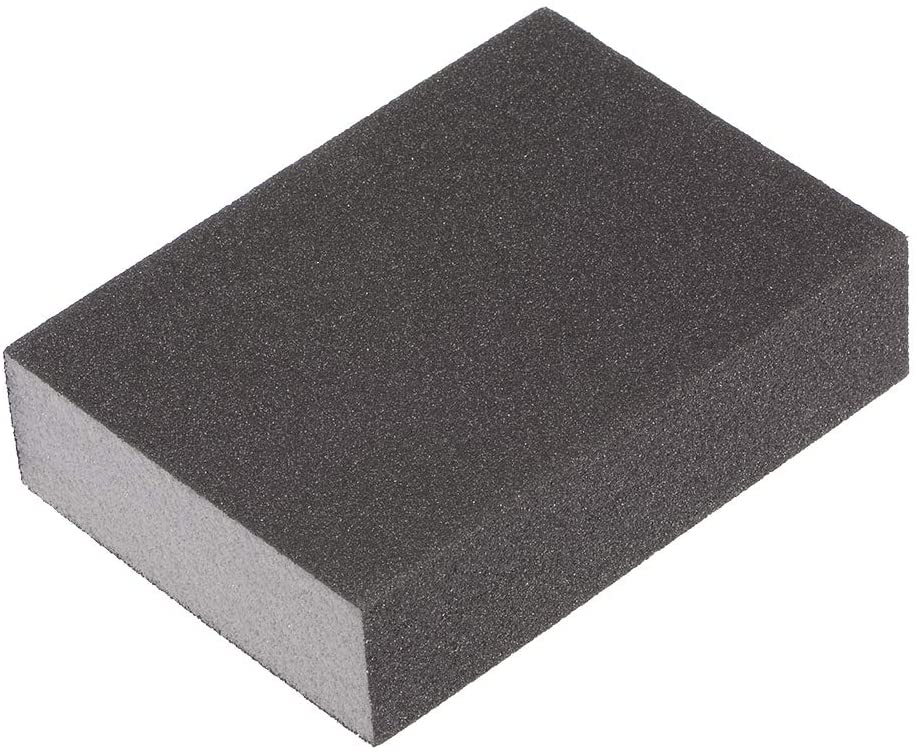

7. Abrasive Sanding Sponges and Blocks: ( Types of Sandpaper )

Grating sanding wipes are blocks made of froth with rough surfaces of various corn meal. They are equivalent to sandpaper. Sanding wipes and squares are compelling for sanding in corners or strange surfaces to which sandpaper won’t adjust. A sanding square or wipe allows the client to apply more strain the hard way, which can bring about a further developed completion.

Tools to Be Used With Sandpaper

- A person sands a wooden step using an orbital sander.

- For sanding projects, consider the following extra instruments. We rent out numerous different types of power sanders.

- In time-consuming activities or those involving vast surfaces, a power sander, orbital sander, or belt sander can be more useful than hand sanding.

- Tack fabric is a cheesecloth which is prone to more of dust and is more effectively cleaned then a wet material across the surface. Wet fabrics can likewise raise the wood grain, making the surface harder to finish.

- Zinc stearate covering is a foamy substance that can be found on certain kinds of sandpaper to forestall obstructing. Sandpaper utilized with zinc stearate covering requires less support yet ought not to be utilized on surfaces with water-based completions

Tips for Using Sandpaper

Here are some of the tips which must be followed for more effective sanding followed by some of its uses:

- The open types of sandpaper are frequently regarded as the best for wood.

- Sandpaper which are found having grains of wood in order to avoid the percentage of clogging the pores on the surface.

- Begin with coarse sandpaper and work your way up to finer sandpaper.

- Large faults should be removed with coarse grits, whereas small-to-moderate flaws should be removed with medium grits. In most circumstances, finishing with a fine grit of 180 or 200 would suffice, however you may require a 220 grit for touch-ups.

- When switching from one grit to another, make sure to clear the work surface because residue from previous sanding can obstruct the smoothing process.

- Don’t press excessively hard. Let the sandpaper’s grating surface accomplish the work.

- Higher corn meal might be required while deciding the best sandpaper for metal, like metal.

- The best sandpaper for hard metals, for example, iron or steel is aluminum oxide, while the best sandpaper for milder metals, for example, aluminum or metal is silicon carbide.

- Determine an opportunity to change sandpaper by running at the tip of your finger over the segment of paper you’ve been utilizing. Assuming it feels essentially smoother than an unpleasant, unused piece of the paper, start sanding with a new area.

Selecting the Correct Coarseness

- To make picking sandpaper simpler, producers recognize a coarseness level in words on the bundle notwithstanding the particular grade. This is basically a scope of coarseness estimates that are likewise powerful for the equivalent sanding work. Truth be told, it’s normal for activities to require a specific coarseness level rather than a particular coarseness of sandpaper, so it’s savvy to realize what each level incorporates.

- Extra coarse sandpaper in the 24-to 36-coarseness range is extreme stuff. It’s utilized for eliminating paint and stain that you think may never fallen off. The sanding of old floors may likewise require the abrasiveness of extra coarse sandpaper. Try not to try and ponder utilizing this stuff on any however the hardest positions.

- The rough shaping of wood and the removal of prior treatments, such as light layers of polyurethane, are the strengths of coarse sandpaper. The coarse grits are observed to have a range within 40 and 50 grits.

- Some final shaping can be done with medium sandpaper with grits ranging from 60 to 100. Medium-grit sandpaper is frequently the best choice for rough wood sanding and the removal of planning marks on wood.

- Fine sandpapers are found being ranging from 120 to 220-grit. This sandpaper will suffice for final sanding before the task is finished in most home workshops.

- Between applications of paint or varnish, extra fine sandpaper is frequently utilised.