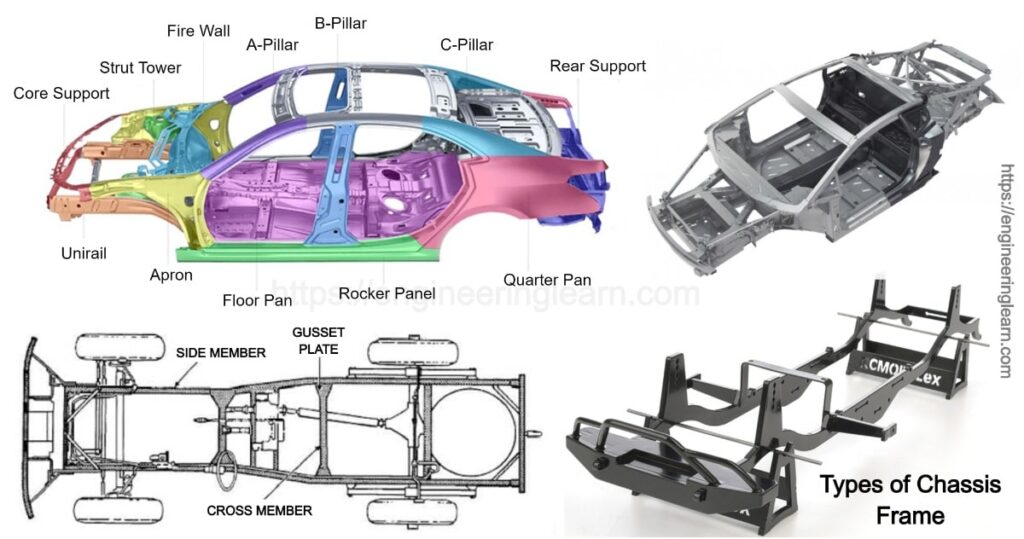

Types of Chassis Frame: Function, Material (Loads Acting on Frame)

What is Frame?

Types of Chassis Frame: Function, Material (Loads Acting on Frame) :- The frame or the under body is important part of the chassis. The remaining part of the chassis is mounted over the frame. The frame is a rigid structure like a skeleton which holds the major parts together. The engine is mounted on the front side of the frame. Clutch and transmission system is also mounted on the front side which completes the power assembly. The frame is supported on the wheels of the body through the suspension system to absorb the shocks.

Functions of Frame

- To carry the chassis and its mountings

- To support the suspension system

- To integrate the chassis and the wheels of the vehicle

- To transfer motion from transmission system to the wheels

Various Loads Acting on Frame

1. Short Duration Loads

These loads are acts when vehicle passes through broken patches of roads and feels a sudden shock. Due to this action vehicle will experience a reaction force which is further acts on the frame of the vehicle.

2. Momentary Duration Loads

When body takes a curve or during cornering body will experience a centrifugal force. This force is transmitted to the frame. This force also acts on the frame.

3. Impact Loads

When vehicle experience an accident then the chassis frame experiences a high impact load which is directly transferred to frame. The frame has to sustain these impact loads.

4. Inertia Loads

These loads are because of the weight of the vehicle itself. When brakes are applied and vehicle comes to rest and experiences huge inertia force due to the vehicle motion on the front side of the chassis, this is called inertial loads. Similarly, when vehicle accelerates the complete vehicle weight is transferred to the back side of the frame. Basically, inertia loads are due to braking and acceleration.

5. Static Loads

These are because of the weight of the vehicle or the weight of the chassis components viz. transmission system, braking system, suspension system, body, accessories of vehicle, and passengers in the vehicle etc.

6. Overhead Loads

These loads are those which are used by engineer to take the factor of safety to sustain the overloading conditions. For example, two wheelers are designed to carry loads of two passengers but in actual the vehicle is designed to carry much more load than two passengers to provide the factor of safety.

Material used in Chassis Frame

The material selection of the chassis frame is dependent on the properties of material such as; • Yield strength • Ultimate tensile strength • Hardness • Weight density • Cost

A) Steel

Since the chassis frame is invented, steel is the most commonly used material. Its yield strength and ultimate tensile strength is less in comparison with its competitive materials for manufacturing of chassis frame. Hardness and weight density of steel is more than aluminum, and the cost is also less.

B) Aluminum

As we discussed earlier aluminum has advantage over steel due to less weight without highly compromising the strength of material. So now a days aluminum is most commonly used as the material for the manufacturing of chassis frame. The only disadvantage is that it has higher cost comparison to steel.

C) Carbon Fibre

This material is used now a days. Carbon Fibre provides excellent properties required for the chassis frame but its biggest disadvantage is that it is very costly. Approximately same amount of carbon Fibre is 100 times costly than steel. Weight of this carbon Fibre is very less so fuel economy and power output are increased. Weight of the carbon Fibre required for chassis frame is quarter of the steel used for the same. This is mainly used in sports cars and bikes.

Types of Chassis Frame

1. Conventional Frame: ( Types of Chassis Frame )

It is mostly used in heavy duty vehicles. This frame is generally made from the steel sections. This type of frame has two longitudinal members and 5-6 cross members. These cross members are joined to longitudinal members with the help of rivets or bolts. The cross members are used to increase the strength of frame. The side or longitudinal members can be parallel but commonly they are tapered.

They are in-swept at front and up-swept at rear. The frame is narrowed down at front to have a better steering lock which gives smaller turning circle and provides space for the pivoting and swinging of the front wheel. The upswept at the rear is primarily to give room for the vertical movement of the rear axle as they travel over road bumps and other surface inequalities.

The body brackets are provided to support the body of the vehicle whereas the spring brackets are provided on the frame for mounting the springs. The extension of the chassis frame ahead in the front axle is known as the front overhang while it’s extension beyond the rear is known as rear overhang.

The cross members and side members can be made up of following cross section:-

• Channel section

• Box section

• I-section

• Hat section

• Tubular section

The channel section and Box section have higher bending stiffness compared to solid square section with same cross section area; therefore both these sections are used for sidelong members.

The I-section, Hat section and tubular section are normally used for cross members.

The side and cross members are usually joined together by riveting, welding or bolted together. The engine, clutch, gearbox and steering are all bolted together to form rigid assembly which is mounted usually on front end of the frame. It is necessary that chassis must maintain the working assembly in their correct position to provide a mounting for the body. Although it adds little for the strength of the structure.

2. Integral Frame: ( Types of Chassis Frame )

This frame construction, is now a days used in most of the motor cars called as a frameless or chassis less or mono or unit construction in which the floor assembly and frame form one integral unit. In this type of construction heavy longitudinal members are replaced by multiple cross members to strengthen the body. The disadvantage of this is that it difficult to repair.

3. Semi-Integral Frame: ( Types of Chassis Frame )

In semi integral type full frame is divided into two section which is mounted on the front and rear part of the vehicle on which engine gearbox and front suspension is mounted. It has the advantage, when the vehicle is met with accident, the frame can be taken out easily to replace the damaged chassis frame.