7 Types of Vernier Caliper: Parts, Working Principle, Least Count & Zero Error [Complete Guide]

What is Vernier Caliper?

Types of Vernier Caliper: Parts, Working Principle, Uses, Least Count & Zero Error :- A Vernier caliper is referred to as an instrument which is commonly used for a variety of accurate measurements, and is not necessarily related just to the engineering manufacturers. There are three types of Vernier caliper which are commonly used in the laboratory in order to measure the lengths of the small objects accurately precisely which cannot be done using a meter scale or any other instrument. So, let’s scroll down to learn more about the types of Vernier caliper. ( Types of Micrometer )

- Type A

- Type B

- Type C.

The foremost use of any Vernier caliper is to measure the internal as well as external diameter of an object. The word caliper is derived which means any instrument with two jaws which is used to determine the diameters of objects. This is the instrument which is well known for obtaining accurate measurements which are highly required for the scientific experiments.

The principle on which a Vernier caliper works is that whenever there are two scales or divisions which are slightly different in size, then the difference within them is used so that the accuracy of the measurement can be increased.

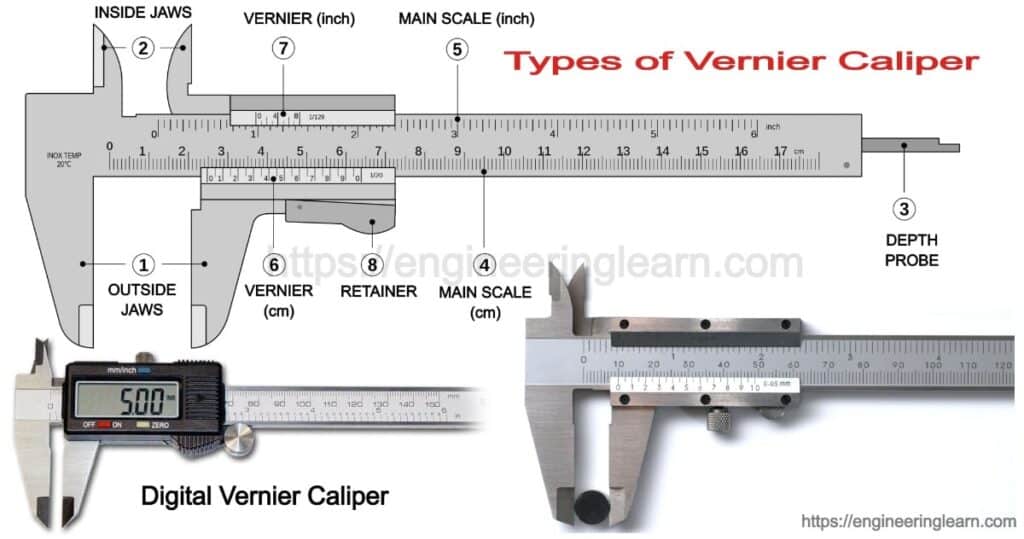

Parts of Vernier Caliper

As a Vernier caliper is high in demand at places where there is requirement of a highly accurate measurement. So here comes a need to properly know the elements of Vernier caliper which are mentioned below. So, the main elements of the Vernier caliper are as follow:

- Main Scale

- Vernier scale

- Thumbscrew

- Lock screw

- Depth Rod

- Fixed jaw, and

- Sliding jaw

- Description

1. Main Scale: ( Parts of Vernier Caliper )

Vernier caliper mostly consists of two steel rules which can slide along with each other. One is observed to be a long rectangular metal strip which has a fixed jaw on one end and is graduated in inches at its upper end, few centimeters at its lower end which is known to be the main scale. The main scale can be seen on the solid L shape frames, on which the cm. markings are divided into 20 parts so that a small division can be equal to 0.05 cm. This is what allows improvements in the popularly used measuring techniques along with the direct measurements using the line graduated method.

2. Vernier Scale: ( Parts of Vernier Caliper )

There is one more, small rectangular metal strip which is graduated along with a special relation to a main scale which is termed as the Vernier scale and slides over this long metal strip when it has a jaw that is similar to that of the main scale. There are two jaws which are found on the Vernier caliper one is the upper jaw and other is the lower jaw. These are the jaws which are used together to hold the object tightly during the measurement of its length which is impossible using a meter scale.

The external jaw which is also known as the lower jaws is generally used to measure the diameter of a sphere or a cylinder whereas the internal jaws or the upper jaws are the ones which are generally used to measure the internal diameter of a hollow cylinder. There is a metal strip observed which is attached at the back of the Vernier caliper and is helpful in measuring the internal depth of a cylinder.

The Principle of Vernier Caliper

A scale cannot measure objects which are smaller than 1mm whereas a Vernier caliper can measure objects up to 1mm. As is well known by that the Vernier caliper is found having two scales the main scale and the Vernier scale, both of this make an arrangement to measure very small lengths like that of 0.1mm and so on. The main scale is found having the least count of 1mm whereas the Vernier scale has the least count of 0.9mm. 10 units of the main scale is equivalent to 1cm whereas 10 units of Vernier scale is equivalent to 0.9mm.

The unit of the Vernier scale is millimeter. This is termed as the main difference within the main scale and the Vernier scale which is 0.1 mm and is also referred to as the working principle of the Vernier caliper.

Least Count Of A Vernier Caliper

The difference within the values of one main scale division and that of a Vernier scale division is referred to as the least count of the Vernier caliper. The least count of Vernier caliper is referred to as the smallest value which can be measured from this instrument. In order to calculate the least count of a Vernier caliper, the value of one main scale division needs to be divided by the total number of division present on the Vernier scale.

For example, if the value of one main scale division is 1mm and the total number of division on Vernier scale is found to be 10mm then the least count will be 0.1mm. Therefore, the least count is known to be the smallest distance which can be measured from an instrument named Vernier caliper.

Zero Error in Vernier Caliper

Zero error in the vernier caliper is referred to as a mathematical error due to which, the zero of the vernier scale does not get coincided with the zero of the main scale. In case the zero mark on the vernier scale does not coincide with the zero mark on the main scale, then the error which is found to occur is termed as zero error. Zero errors are found to be of 2 types which are as follows:

- Positive zero error

- Negative zero error

1. Positive Zero Error

In the case of positive zero error, if these jaws are brought together the observer can see the zero of Vernier scale will be ahead of main scale zero. It can be said that the zero of the Vernier scale is at the right side of the main scale zero. In both the cases either it is ahead of the main scale zero or it would be at the right side of the main scale zero. This is referred to as the zero error which is positive.

2. Negative Zero Error

In case of negative zero error, once both the jaws are brought together the observer can see zero of the Vernier scale which is at the back side of the main scale zero or can also be at the left side of the main scale zero. So in case the Vernier scale zero is found to be at the backside or to the left of the main scale zero then in both the cases, zero error is found to be the negative error.

3. No Zero Error

In no zero error, once both the jaws are brought together the observer can see zero of the Main scale coinciding with the zero of the Vernier scale. If they are exactly in a straight line then the Vernier caliper is said to be free from zero error or can be said that there is no zero error in this Vernier caliper.

Types of Vernier Caliper

The below mentioned are the different types of Vernier Calipers:

- Flat edge Vernier caliper

- Knife edge Vernier caliper

- Vernier gear tooth caliper

- Vernier depth gauge

- Flat and knife edge Vernier caliper

- Vernier height gauge

- Vernier dial caliper

1. Flat Edge Vernier Caliper: ( Types of Vernier Caliper )

Flat edger Vernier caliper are referred to as the type of Vernier which is used for normal functions like the outer measurement of length, breadth, thickness and diameter. As its edge is found to be of a special type, the inner measurement can also be taken along with it. Whereas from that measurement, the breadth needs to be subtracted. This type of measurement is often written on the jaw otherwise it should be measured with a micrometer.

2. Knife Edge Vernier Caliper: ( Types of Vernier Caliper )

Knife edge Vernier caliper are the Vernier which have the edges like a knife. This Vernier caliper is mainly used at places where there are narrow spaces, distance of holes of I bolt etc. Its importance is due to the thin edge of its jaw which wears out quickly and starts giving an inaccurate measurement. This type of Vernier should be used sparingly and carefully.

3. Flat And Knife Edge Vernier Caliper: ( Types of Vernier Caliper )

Flat and knife edge Vernier calipers are referred to as those which have their jaw like an ordinary Vernier caliper from one side whereas have knife-edge jaw at the other side. These types of Vernier calipers can be used to perform all types of jobs, as it can measure everything easily.

4. Vernier Gear Tooth Caliper: ( Types of Vernier Caliper )

Vernier gear tooth caliper is referred to as a special type of instrument, which is made from a combined form of two Vernier calipers. This type of Vernier consists of two separate scales, one is the vertical scale and the other is the horizontal scale. In the Vernier caliper, the thickness of a tooth of gear can be taken from the pitch circle or it can be said that the Vernier caliper is used to measure various parts of the gear.

5. Vernier Depth Gauge: ( Types of Vernier Caliper )

Vernier depth gauge is referred to as an instrument which is used for the measurement of the depth of slot of any particular job like its hole or groove. This type of Vernier is almost similar to that of a Vernier caliper and the reading is also taken in the same way but it is found having a flat-shaped base which is used instead of a jaw.

The depth gauge is made using a thin beam like a narrow rule and the main and Vernier scale are also found in either inch or metric system. The main purpose of such Vernier is that the observer can take measurement of three types with it:

- The main scale is found to be marked in parts of inches and is also divided into 64 sub-sections.

- The other end is found having 40 sub-sections and every fourth line being slightly bigger. It contains the local size with a minimum measurement of 0.001 and is taken by the help of a Vernier scale.

- The readings are found in mm which can take a minimum measurement of 0.02 mm along with the help of a Vernier scale.

6. Vernier Height Gauge: ( Types of Vernier Caliper )

Vernier height gauges are used for making the accurate measurement of height or for any marking with the highest required accuracy. This types of instruments are quite similar to that of a Vernier caliper whereas it is used by attaching some of the additional attachments. The beam if found fixed on the base in length form. Also the off-set scriber is fixed on the beam itself using which the height of a job is measured or the marking is done. These are further classified into two different types:

- Solid Base

- Moveable Base

In solid type of Vernier the there is no facility to set the beam or base as per the requirement of the site whereas in the moveable base Vernier, this facility is found to exist. This is the type of Vernier height gauge which is in the form of a set and has a base Vernier caliper, offset scriber fixing screw etc. These are the types of Vernier height gauges which can be used as an ordinary Vernier caliper by separating its base. In order to use both the types of Vernier height gauges, it is mandatory to keep in mind the following points:

- Ensure using it on a plain surface of the jobs.

- Avoid giving excessive pressure while marking to avoid breakage.

- To be used on a surface plate only.

- To be used only for précised marking or measurements.

- The readings should be noted down.

7. Vernier Dial Caliper: ( Types of Vernier Caliper )

In a Vernier caliper there are found chances of mistakes as far as reading is concerned. So to avoid these things, nowadays Vernier dial calipers are being used which have replaced the Vernier scale and also contains a graduation dial in order to avoid the reading error.

Similar to Vernier calipers, these are the instruments which can be used to measure the dimensions in inches as well as in millimeters. Similar to a dial test indicator, a rack and a pinion are also used in these venires. The rack is found to be on the main scale that is connected to the pinion of the dial. This type of movable jaw are the ones which move by the thumb roller in order to take the reading, for this there needs to be a check on how many main and sub marks an inch the bevel edge of the movable jaw which has crossed and added the reading.

Type A, B, and C Vernier Caliper

Vernier calipers are broadly classified on the basis of an international standard 3651-1974. According to this standard there are three types of Vernier calipers which have been specified to meet the external and internal measurement requirements of up to 2000mm with an accuracy of 0.02, 0.05 and 0.1 mm. The different types of Vernier calipers are classified as type A, type B, and type C.

1. Type A Vernier

This type of Vernier is made with only one scale which is located on the front of the beam and enables direct reading. These Vernier’s are found having jaws on both the sides in order to calculate the external and internal measurements. It is also found having a blade for measuring the depth. The calipers are made of very good quality steel along with the measuring faces hardened to 650 HV. The beam is designed flat throughout so that its length comes within the tolerances for the nominal lengths from 900 to 1000mm, for 1500 and 2000mm sizes.

The guiding surface of the beam is made linear within 0.01mm in order to measure the range of 200mm and 0.01mm. As per IS 3651-1974 there are nominal sizes for measuring which are as follows:

0mm-125mm, 0-200mm, 0-250mm, 0-300mm, 0-500mm and 0-750mm.

This scale serves well for both external as well as internal measurements. The jaw which is fixed is made an integral part of the beam wherein the sliding jaw is made of a good sliding fit along with the beam which is made to have seizure free movement along the bar.

2. Type B Vernier

Type B is referred to as those Vernier’s which are made of only one scale, located on the front of the beam so that direct reading can be taken properly. These are the type of Vernier’s which provided with jaws on either side for external as well as internal measurement. The beam is purposely made flat throughout its length to withstand the tolerances of 0.05mm for nominal lengths up to 300mm, 0.08mm from 900 to 1000mm and 0.015mm for 1500 and 2000mm sizes.

The main scale which is served as an external measurement and internal measurements are the ones which are made by adding the width of an internal measuring jaws to obtain the reading on the scale.

According to IS code 3651-1974 nominal sizes for measuring are as follows:

The scale is found serving both external as well as internal measurements. The measuring surfaces are found having a quite fine ground finish so that the portion of the jaws within the beam and the measuring faces can be relieved. The jaw which is fixed is referred to as an integral part of the beam whereas the sliding jaw is made a good sliding fit along with the beam and made to have seizure free movement along the bar. The size measurement of these types of Vernier’s is found to be quite similar to that of type-A.

3. Type C Vernier

The type C Vernier’s are referred to as those Vernier’s which are quite similar to type A and B and are also made of only one scale which is located at the front of the beam, so that direct reading can be done. These are the Vernier’s which are found having jaws on both the sides so that the measurements and marking operations can be made.

The beam is purposely made flat along its length to withstand the tolerances of 0.05mm for nominal lengths varying from 300mm, 0.08mm from 900 to 1000mm and 0.15mm for 1500 and 2000mm sizes.

The surface which are to be measured are given a fine ground finish and the portion of the jaws within the beam along with the measuring faces that are relieved. The jaw which is fixed is referred to as an integral part of the beam so that the sliding jaw is made a good sliding fit along with the beam and is found having seizure free movement with the bar.

Working of Vernier Caliper

As off now almost each and everything must have been known about the instrument, Vernier caliper. Whereas it’s working is still not known, and is an important thing which one must know.

You must be able to find a sliding jaw which is located and is found responsible for running on the main scale along with the guiding surface and accompanied with a Vernier scale, wherein it is found having a measuring tip on its left side. If there are found two measuring tip surfaces that are found to be in contact with each other than the scale is found having the zero reading. Considering the adjustments of any movable jaw, it must be said that the adjustment which are finer of the movable jaw can be achieved by adjusting the screws.

In the initial times, the entire movable jaw assembly has a need to be adjusted so that both the measuring tips can touch the parts which are in need to be measured. After which the lockout B is tightened properly. The final adjustments are those which depends upon the sense of correction factor and is made simply by adjusting the screws so that the part which contains locking nut A and sliding jaw can move properly, the adjusting screw is found rotating on a screw which is in a way fixed to the movable jaw.

As soon as all the final adjustment have been done then the locking nut can also be tightened, after which the reading can be noted easily.