18 Types of Welding Tools and Their Uses [with Pictures & Names]

![18 Types of Welding Tools and Their Uses [with Pictures & Names]](https://engineeringlearn.com/wp-content/uploads/2021/11/Welding-Tools-1024x539.jpg)

Introduction of Welding Tools

Types of Welding Tools and Their Uses [with Pictures & Names] :- Welding tools are referred to as those tools which are mandatorily required to fulfil the welding job. There are various types of tools which are found being working with so much heat and so many pressurized components that can be even dangerous but might seem to be overwhelming. Although there is nothing much to fear. Here is a list of some of the welding tools which are found working through the trade safely as well as efficiently. ( Types of Welding )

Types of Welding Tools

1. Auto-Darkening Welding Helmet: ( Types of Welding Tools )

Auto-darkening welding helmet is one of the most basic as well as recognizable piece of welding equipment which one can get. The welding helmet is found to be a staple of the craft which is proved to be a safety necessity. ( Types of Welding Joints )

The primary purpose of such types of welding helmet is to prevent the sparks as well as the flames from scarring your face during the working and to also prevent the damage to the skin as well as the eyes from the heat.

Auto-darkening helmets are the ones which are found adding the feature of protecting your eyes from the harsh lights which are being emitted from other welding tools and also from the heated metal itself.

The glass covering wherein the eyes are found being shaded to be the ones which only allow a certain amount of light through at a time. This is what allows you to see without damaging the vision of the worker.

There are various types of auto-darkening helmets too, the list of which can easily be known, amongst which the best can be selected according to the site requirement.

2. Welding Gloves: ( Types of Welding Tools )

Gloves are referred to as one of the most self-explanatory gloves. Welding gloves are the ones which are found consisting of layers of the robust fabrics along with its insulation that prevents its injuries from heat as well as the stray sparks. Welding gloves are the ones which are found easy to find anywhere from where you buy the gloves whereas they are essentially known to any form of welding you might do.

There are usually 2 types of gloves which you need to be aware of:

A) MIG Welding Gloves

MIG welding gloves are referred to as those gloves which are found to be generally thicker and also has padding on the back of the hand in order to protect your resting hand during the process of bracing the dominant hand while the weld continues. In case the gloves are found being too hot, then the looser fitting design are also available which allows you to throw them off easily.

B) TIG Welding Gloves

TIG welding gloves are referred to as those gloves which are thinner as well as softer gloves where the precision seems to be vital. TIG welding gloves are found having a tighter fit in order to allow the precise movement while holding the rod as well as the torch. Make sure you select the most appropriate gloves for the correct job.

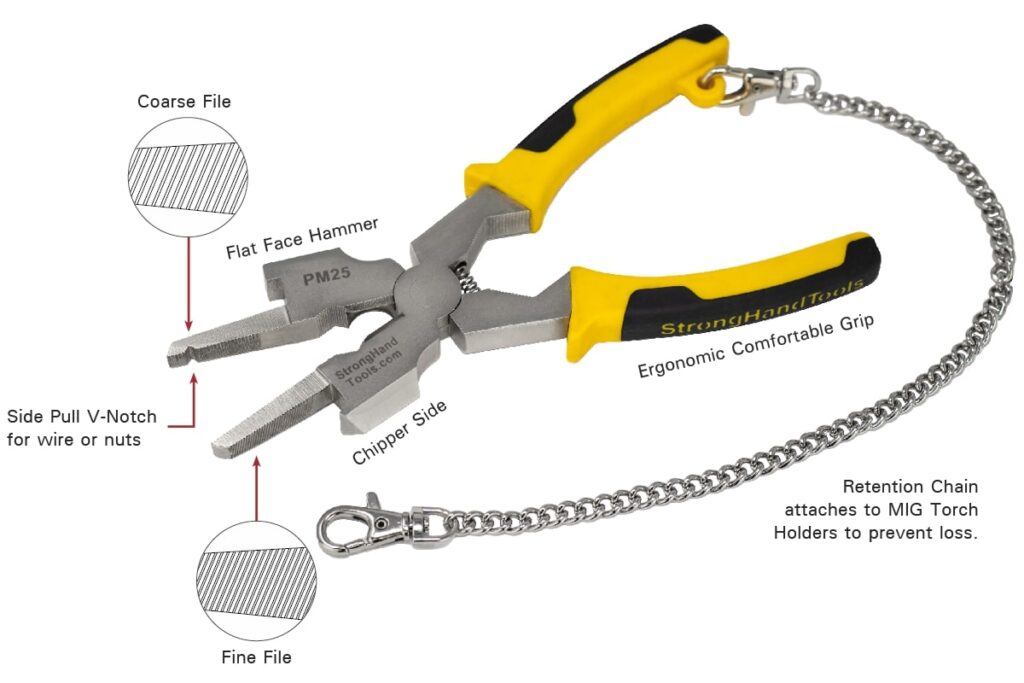

3. MIG Welding Pliers: ( Types of Welding Tools )

MIG welding pliers are referred to as one of those welding equipment which are widely available in most hardware stores as well as at the online platform. These pliers seems to be far from a specialty item as well as are found to be pretty cheap in comparison to any other tool.

They have several uses which include:

- Removal of the nozzle from MIG gun – They are found being equipped with the circular clamps which seem to be perfect for removing the nozzles from the MIG gun.

- Loosen & tighten contact tip – This is the one which is used regularly as it gets worn out easily.

- Cut 1/4″ Stick-Out – Saves time instead of using any separate wire cutter.

- Cleaning the inside nozzle from the spatter is the one which is easy along with the tips of the pliers.

- A quality pair of MIG pliers is something which seems to be essential if you own a MIG welder.

4. Welding Magnets: ( Types of Welding Tools )

Welding magnets are referred to as one of the most versatile tools which you will definitely have in your kit. That is what makes them so useful while welding.

Along with a welding magnet, there are found some of the holding pieces of metal in place without the use of clamps in order to manipulate them easily.

They are also known to be mounted pieces for the metal and weld them at an angle to one another.

They allow for some pieces of sheet metal which need to be welded in ways where the clamps would not be allowed. As long as you use these, the more uses you will be able to find for them.

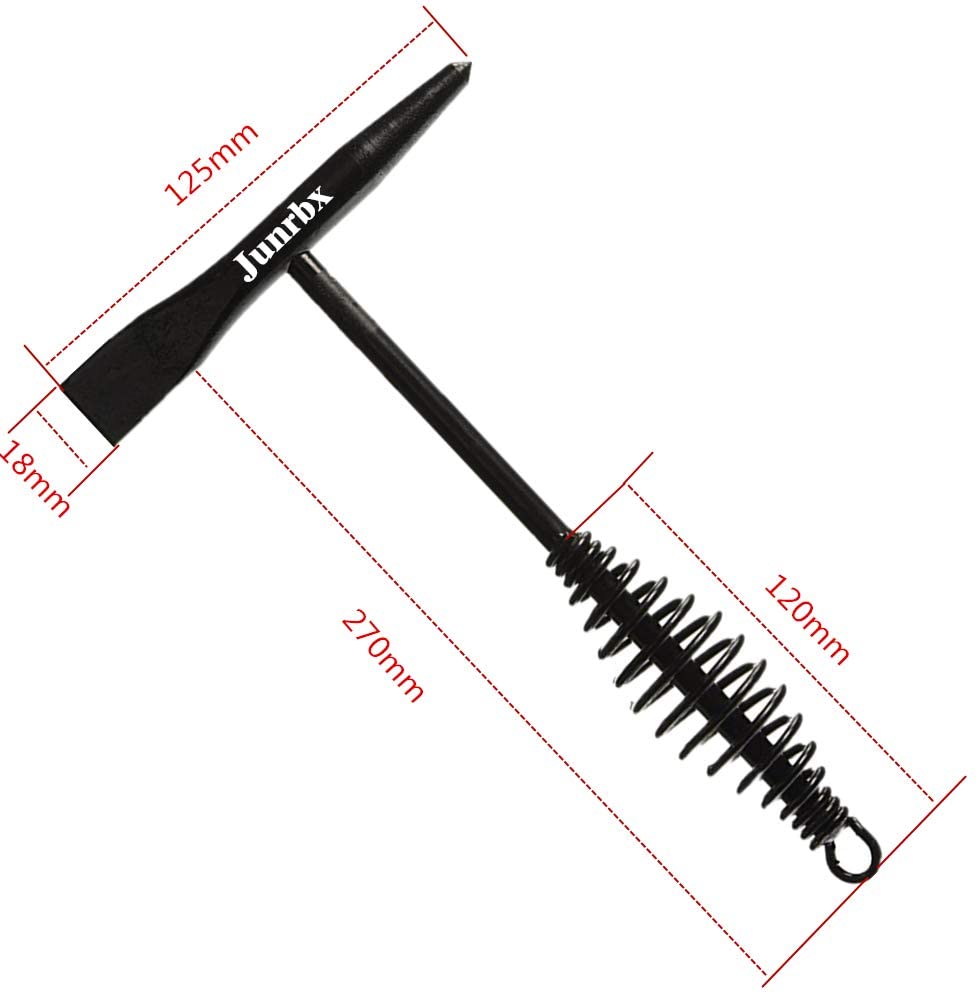

5. Chipping Hammer: ( Types of Welding Tools )

Chipping hammer is referred to as one of the renowned facet of MIG welding or stick welding which is known as the condensation of a slag as the metal seems to melts and thus form into the weld.

This slag is found having the need to be chipped away at times, for which the chipping hammer is known. These are found having a flat side along with a pointed side in order to get optimized for different kinds of slag.

These kinds of hammer might not be used overly often whereas they make the process of welding much cleaner as well as more manageable as compared to any other tool.

6. Welding Framing Jig: ( Types of Welding Tools )

A welding framing jig is referred to as that tool which is not on the same level of necessity as compared to the other items on this list whereas it is also one of the most renowned equipment to have.

The main work of a welding framing jig is to provide an apparatus for the purpose of welding at an angle of 90-degrees. In case you could use a welding magnet for this purpose then a framing jig is also found allowing for a much greater degree of support during the process of welding which allows for heavier metal pieces to be used.

Unlike the other magnets with varying electromagnetic range, it is found also allowing for various layers or the multiple components that need to be tack as well as welded together at the same time, at an angle of 90-degree.

7. Speed Square: ( Types of Welding Tools )

A speed square is referred to as the tool which you use with the most out of any of the things that are found being listed here. These are referred to as those tools which can measure almost any piece either perpendicular or another for an angle of 90-degree cut or at any other angle along with your speed square.

A speed square is known as an angular measuring device which is particularly shaped like a right triangle that allows for the multiple forms of measuring the different angles.

8. Metal Brush: ( Types of Welding Tools )

Metal brush is referred to as something that one might not think about the constant use of welding.

A metal brush is known to be the one which removes the slag as well as charring from the top of cooled welds that leaves the whole thing looking nice and clean.

Not every welding process is the one which creates slag whereas there are other ones that do require both chipping hammers as well as the metal brushes in order to do the work properly.

9. Angle Grinder: ( Types of Welding Tools )

If you are much into the welding jobs regularly, then there is an angle grinder which can be a very useful tool in order to have your toolbox perfectly ready.

These types of tools are highly essential as they have the capacity of cutting down the metal. You will find the need to cut down some of the metal stock along with a cut wheel using which you can easily cut anything by simply using the sheet metal to bar stock along with the surprising ease.

Angle grinders are the ones which are mostly found quite useful in order to prepare the metal before the welding takes place. To avoid the types of defects like porosity or cracking, you might want to clean the base metal. While this can also be done by simply using a wire brush at a particular angle grinder which can save you a lot of time.

Finally, the welding angle grinder referred to as that tool which seems to be best for cleaning up as well as for finishing the welds. Whenever there seems to be a lot of slag left over by using an angle grinder there can be one effective way by which it gets cleaned up. Other than this, in case if there is a need to polish up the metal on which you are working then an angle grinder can very easily do that.

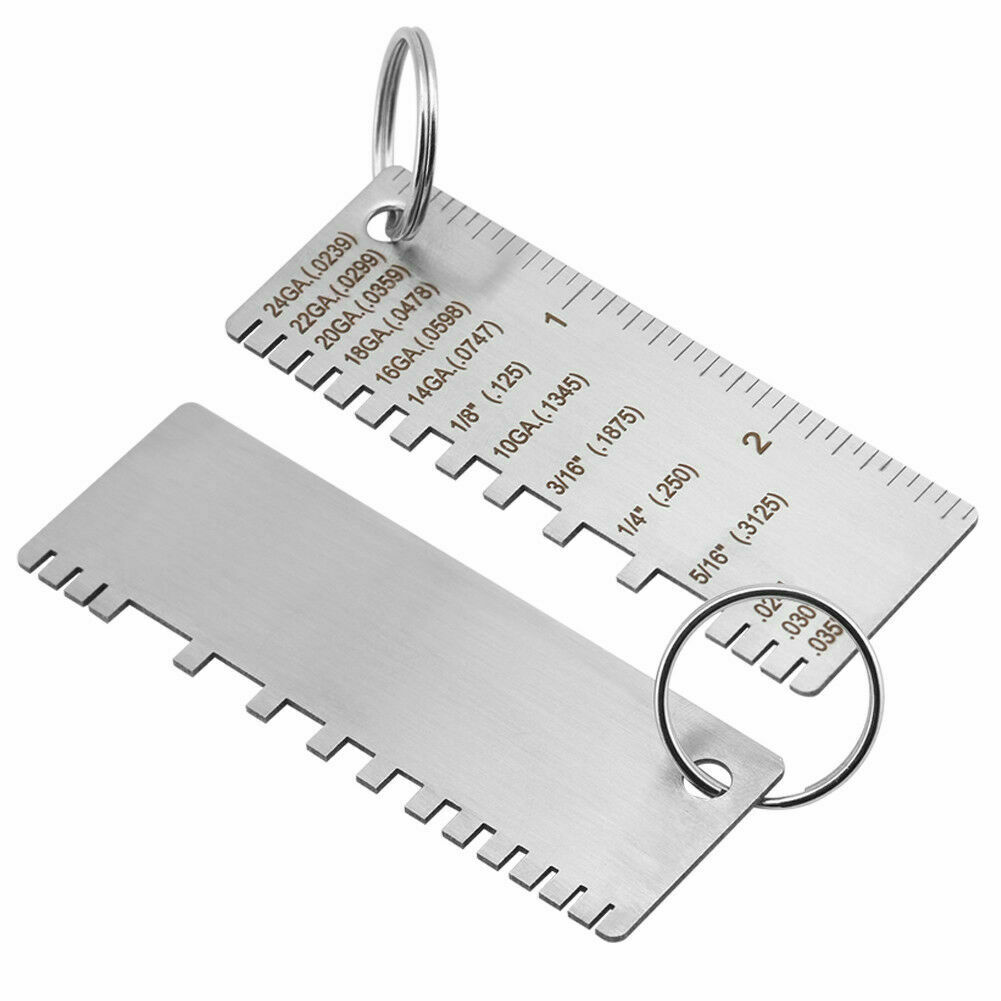

10. Sheet Metal Gauge: ( Types of Welding Tools )

In order to weld more effectively there is a need to know the thickness of the metal you are working with. A steel metal gauge is known to be a wheel along with a teeth which is found being spaced with different widths apart from the corresponding sheet metals with various standard widths. The sheet metal gauge is known to be one of the most indispensable type for the purpose of welding of any type of skill level.

If you are confident enough, and you know how thick a metal sheet on which you are working is, then you can very well determine a lot of other things about your project in general in order to execute the work in even better way. There are various professional welders which are found having a chart that merely says what all settings they should use for the purpose of thickness of sheet metal.

There can be time spans wherein it can be hard to distinguish any one piece of sheet metal from another by simply looking at it which would mean that the gauge will come in handy position constantly.

11. Soapstone: ( Types of Welding Tools )

The soapstone is usually confused with the material which is made of soap whereas it is not appropriate. Whereas its markings implement its similar consistency. You use a soapstone in order to mark or implement which is easily removed once you are done. You must think of it as a piece of chalk which is made specifically for the purpose of writing on any type of metal.

Soapstone is the one which seems to be quite superior in reference to something like the material graphite as it can withstand the higher impact of heat as well as assault of flames from torches and other welding tools as well. These are the type of tools which allows you in order to draw the complex shapes, curved lines as well as the other designs in addition to write the things which are found directly on the metal.

12. Metal File: ( Types of Welding Tools )

Metal file is referred to as that tool which is found to be quite similar to the angular grinder. The primary use of the metal file is to remove the rough edges as well as the burrs from the metal that are found being cut.

Metal files are the ones which are commonly used for the purpose of all kinds of other metalworking projects which you might have probably used them before at some point. There are the angular grinders that seem to be quite good at the rougher removal process wherein the files are found finishing as well as making the project look even better in terms of looks and finishes.

13. C-Clamp: ( Types of Welding Tools )

C clamps are referred to as that clamps which are most commonly found being similar to the letter C. These are the clamps which are found applying the pressure from the upwards as well as downward direction at the same time which seems to be endlessly very common for a wide variety of hardware projects not just keeping it limited to welding.

C clamps are the ones which are found allowing a greater amount of pressure as compared to the pinch clamps or even some of the welding clamps that are responsible for allowing for a much more solid hold on whatever you need in order to clamp properly.

14. Welding Boots: ( Types of Welding Tools )

Foot injuries are known to be one of the most common as well as least discussed work-related accidents that take place while working on such sites. There is an estimated 25 percent of all type of disability applications which seem to be resulting in terms of foot injuries on the job.

There is a need to protect your feet from the hot metal as well as the heavy equipment where you will be working while welding. Any pair of welding boots needs to be as robust as possible. Stout leather as well as steel-reinforced toes are a must. The intent of the boots is to protect your feet from getting melting metal to fall on them.

15. Welding Cart: ( Types of Welding Tools )

The welding cart is referred to as less of a tool along with various other means of moving other tools around. Air tanks are known to be quite heavy, the fans also seem to be heavy. Gas tanks are also observed to be heavy.

A welding cart is known to be the one which is found allowing you in order to move all of these things which are found being more easily as well as more efficiently available. There are some welding carts that seem to have the tool boxes which are being attached to them and seem to give a nice spot for everything else.

16. Welding Sleeves: ( Types of Welding Tools )

Welding sleeves are referred to as those tools which are found having the same category along with the welding boots in that they are vital to your safety while welding but are not commonly discussed. Welding sleeves are the ones which are known having the detachable sleeves and are also made from leather or other non-flammable and robust fabric that protects your clothes and skin from damage.

Most welding sleeves are found being attached to an apron which have their own suspenders in order to hold them in place while welding. Others are the ones which have something closer to a collar that seems to be attached to the sleeves for comfort as well as for added protection.

17. Safety Glasses: ( Types of Welding Tools )

There is not only the need of a welding helmet on for the welding time, there is also a need of reliable pair of safety glasses which are perfect for such type of welding jobs.

Safety glasses are found to be the one which is made from the durable plastic and stop sparks off of something like an angle grinder from flying into your eyes.

18. MIG Welding Nozzle Gel: ( Types of Welding Tools )

Nozzle gel is referred to as another one of those things that are critically important for the purpose of welding but often overlooked. Nozzle gel is responsible for preventing the metal nozzle of your torch from adhering to the metal you are welding.

Image Source :- stronghandtools,