Types of Power Hammers: Functions & Uses

What is forging Power Hammers?

Types of Power Hammers: Applications, Operation & Uses :- The power hammers are the mechanical devices which are also known as forging power hammers which depends on steam in order to create pressure. The latest version of such hammers come with either a pneumatic or an electric hammer. In the layman’s language it can be said that the hammer works when the force is applied in the opposite direction of the rapid movement wherever the object is held.

These mechanical devices uses some or the other type of pressure which is responsible for creating force. The strike is quite faster and is hit with greater force as compared to the force of a hydraulic press. Considering the size of any hydraulic press the power hammers are also quite large in size as compared to the other tools.

The higher the amount of force, the larger would be the required result. The machinery and old models can occupy more space wherever it is supposed to be placed. These are preferred in order to produce smoother as well as uniform outcomes as the sheer mass of the device receives the required vibrations and movements through weight. Here are some of the main types of hammers along with its applications. Scroll down to learn more.

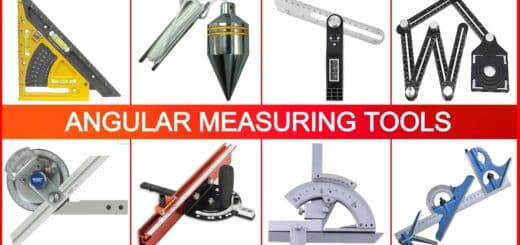

Types of Power Hammers

There are various different types of forging power hammers which are widely used in the market.

- Pneumatic Hammers

- Steam or Air Hammers

- Helve Hammers

- Hydraulic Power Hammer

- Lever-Spring Hammers

1. Pneumatic Power Hammer: ( Types of Power Hammers )

Pneumatic power hammers are quite typical form of mechanical devices which is responsible for carrying the cylinder in which the piston works. This piston is found to be connected to the main motor shaft by the help of a crank and a connecting rod mechanism. A hand lever is also involved which operates the air valve. The air valve is provided through the different cylinders. Another piston also works inside the cylinder which carries the tup at its bottom and is made to slide fixed guides. In order to make the tup move, the piston in the cylinder is moved downwards in order to create the vacuum above the piston inside the other cylinder. This is responsible for providing a suction effect on the piston due to which the tup starts lifting.

Near the end of an upward stroke of the piston, in-cylinder, the air is forced from one cylinder to another where the air is compressed due to the upward stroke of the piston. This is responsible for forcing the piston and thus moving the tup downwards with high velocity. This operation is repeated on regular basis and the required blows are obtained.

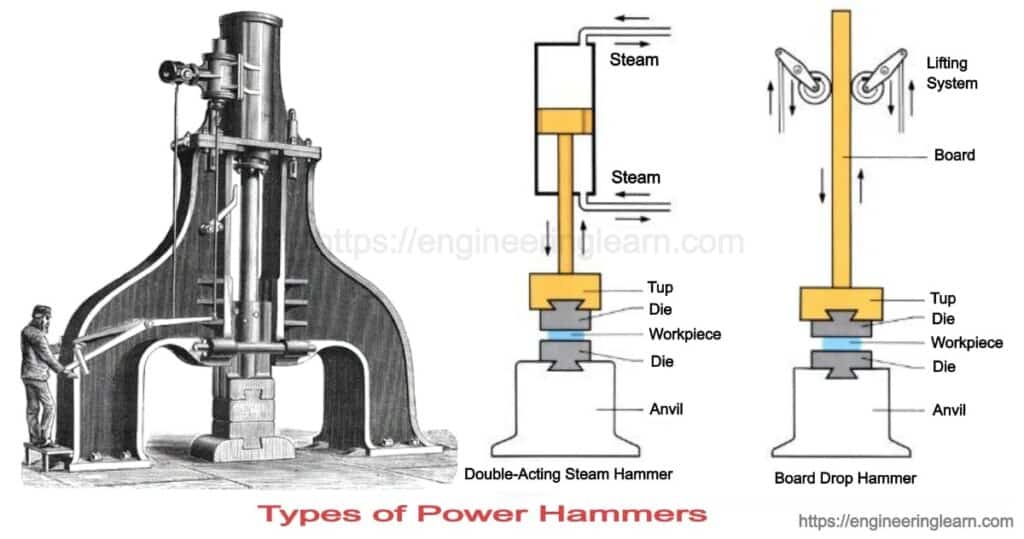

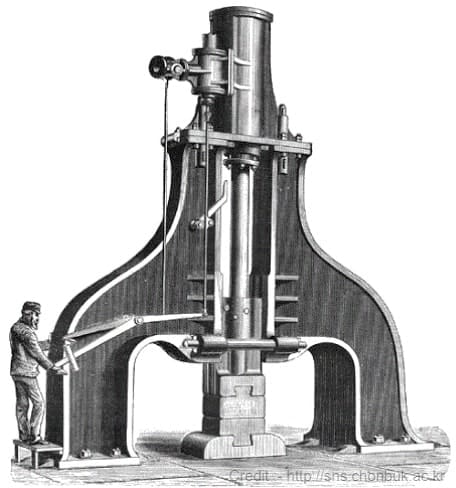

2. Steam or Air Power Hammer: ( Types of Power Hammers )

A steam-power hammer is referred to as those which can be performed by the effect of either steam or compressed air. These are the device which includes a moving ram, rod, piston, a lifting tool, a double-acting high-pressure steam cylinder, housing or frame and anvil. These are the forging power hammers wherein the steam gets entered initially and then at the bottom of the cylinder, the piston gets lifted upwards along with the other moving parts. The amount of force is considered as 3m/sec whereas the mass of the moving parts is nearly 5000kg.

Whenever the blow is required, the lever gets energized automatically where the top sliding value is opened in order to receive the steam from the above of the cylinder and the exhaust steam which remains on the bottom. Thus the required blows are obtained.

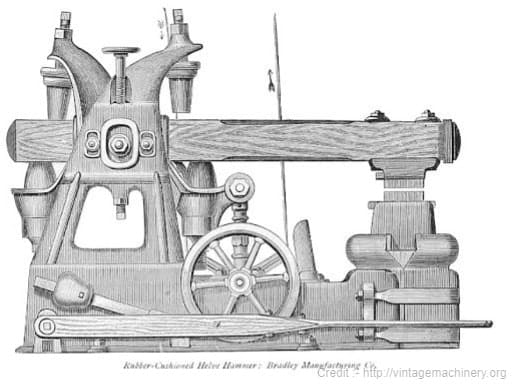

3. Helve Power Hammer: ( Types of Power Hammers )

A helve power hammer is also referred to as a trip or tilt power hammer which is a huge powered hammer. These are the types of forging power hammers wherein more than one helve hammer is installed in a forge which is also referred to as a hammer mill. These forging power hammers are normally lifted with a cam which is suddenly released to drop the force of gravity. The helve hammers are the mechanical devices which are mostly hydraulically driven by a water wheel.

Also, these are used in order to make blooms, made of iron into a more workable bar iron in the finery forges. Other than this, they are also employed in order to fabricate different articles of wrought iron, latten (brass), steel and various other metals.

4. Hydraulic Power Hammer: ( Types of Power Hammers )

The hydraulic hammers is also termed as hydraulic presses which uses 200 to 300 times higher oil pressure as compared to the atmospheric pressure in a hydraulic cylinder. The hydraulic presses are applied in heavy forgings which consists of a press and a hydraulic drive. The rate of production in hydraulic presses is observed to be faster as compared to the other hammer forgings through which the single squeezing action is completed.

The hydraulic hammer is found having low noise and vibration as in these type of devices the speed, blow pressure and die travel, is controlled automatically. The presses which can provide a force of 75000 tons are quite common these days. The hydraulic presses are used in forging industries which widely range from 1000 tons to 10,000 tons. These presses are mostly used for the production of nuts, bolts, screws and rivets.

5. Lever Spring Hammer: ( Types of Power Hammers )

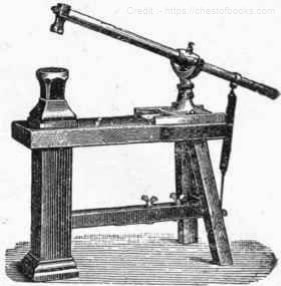

A lever-spring hammer is a quite light type of power hammer which is mostly used for small forgings. These types of hammers consist of a heavy frame with a vertical projection at its top which acts as a housing to bearing in which the laminated spring is found oscillating. There are two ends of this string wherein one end is responsible for carrying a connecting rod and the other end a vertical tup. The tup is responsible for carrying the weight and moves vertically upwards and downwards within the fixed guides.

The connecting rod is attached with an eccentric sheave at its lower end. Further the eccentric sheave is connected to the crank wheel which is responsible for operating the hammer and pressing the treadle downwards. This is what makes the sheave rotate through the crank wheel and therefore the laminated spring starts oscillating in the bearing. This continuous oscillation of the spring leads the tup to move upwards and downwards. Therefore, the required blows are provided on the job and the hand lever is operated in order to adjust the stroke of the connecting rod and the intensity of blows.

Application of Forging Power Hammer

The forging power hammers are being used since 1880s by blacksmiths. It is referred to as a type of machine tool which is used in the forging operations. Other than forging, these devices are also used to close the rivet and strike the steel tools. The design and the use of a forging power hammer is quite similar to a manual hammer which cuts and welds more accurately.

How is a Power Hammer Is Rated?

Power hammers are mostly rated by the weight of the moving parts which depends upon the parts upon which they are worked. Let’s have a look on some of these parts:

Upper Die

Upper dies is a tool which is used to cut or shape a material.

Ram

Ram is the level of force and speed which is imposed on the work piece.

Mechanical linkage Arms

Mechanical linkage arms are responsible for managing the forces and movement upon the work piece which are also referred to as joints. Arms can be built by the open chains, closed chains, or a combination of both. The most important point to note is that any specific element of the design of the hammer is dictated by the power source. To completely understand the function of a power hammer, it is really important to analyze various types of power sources along with the purposes of this tool.

Functions of Power Hammer

There are various types of power hammers that are found having different functionalities and purposes. These different hammer types and the functions are as follows:

1. Mechanical

These hammer are mostly powered with an electric motor and are found in a smaller size and a narrow structure. This is what limits the type of work which they are able to do due to the smaller opening which prevents the use of any external tool. These types of instruments are very powerful in drawing down the metal pieces and were specifically designed for re-sharpening and re-edging agricultural tools.

2. Utility

These mechanical devices are quite similar to the air hammers, other than one factor which is to provide your own compressor. These are mostly powered with three 5-HP two-stage compressors. The three motors are responsible for feeding a manifold pipe with a singular pipe in order to feed power into the hammer while it is in use. This type is not compulsory whereas, it is more complicated to put it in use as compared to a mechanical hammer.

3. Self Contained

Self- contained are the types of hammers which has its own built-in air compressor and tank. The device is quite useful type of power hammer, which is found to be universal and fits all types of hand tools in the throat, which is generally sized at about 12-14 inches (30-35 cm). The main advantage of this machine is the vibration absorption capacity as more it absorbs, it will requires less maintenance on the hammer and also less of a strain on the person who is operating the work piece.

It must be noted that the power hammers along with the specific self-contained hammers are usually not ideal for a beginner blacksmith, as they are not aware about the level of force. In case, you are looking for blacksmithing as a trade or hobby, then it is very important to familiarize yourself with a manual hammer in order to learn the usage of a power hammer. If you are skilled with a manual hammer, then it is suggested to learn to operate and use a power hammer which is an addition to anyone’s skills in forging. Once you have had a knowledge about a power hammer and its functions then it can be a good idea to review whatever a power hammer is used for, specifically in blacksmithing.

Uses of Power Hammer

Power hammers are the tools which are used mainly in the forge welding process. Other than forging, these tools are also used for closing rivets and striking steel tools. The main purpose and application of a power hammer is quite similar to a manual hammer. In order to understand the purpose of a power hammer, there is a need to understand a little more about the forging process.

Forging Process

Forge welding is referred to as a process which is used to join two pieces of metal by heating them to a high temperature in order to loosen the metal and hammering them. This was the practice which is mostly done manually, referred to as a process which is quite unique to itself. The process of forging for a power hammer is a quite simpler process wherein the metal gets heated, after which it is placed under the hammerhead of a power hammer.

Whenever it is used in forge welding, the power source of the hammer gets raised to the hammerhead in order to prepare it for striking the metal and then accelerate it onto the weld. The manual hammers like a ball or cross pin are usually a more common choice selected during forging. The power hammer is referred to as a decent choice best for a hard and accurate hit from a hammerhead.

The magnitude of force which is usually imposed through a power hammer on metal can be compared to the work of two strong labors by the help of a sledge hammer. These mechanical devices are quite powerful due to its weight which has a high level of force upon the piece being welded. Concluding about it, it can be said that it can produce an accurate weld and a high-quality metal piece.

Image Source :- Pinterest, Chonbuk, Vintagemachinery, openlearn