Types of Fuel Pumps: Mechanical, Electric & High Pressure Fuel Pump

What is a Fuel Pump?

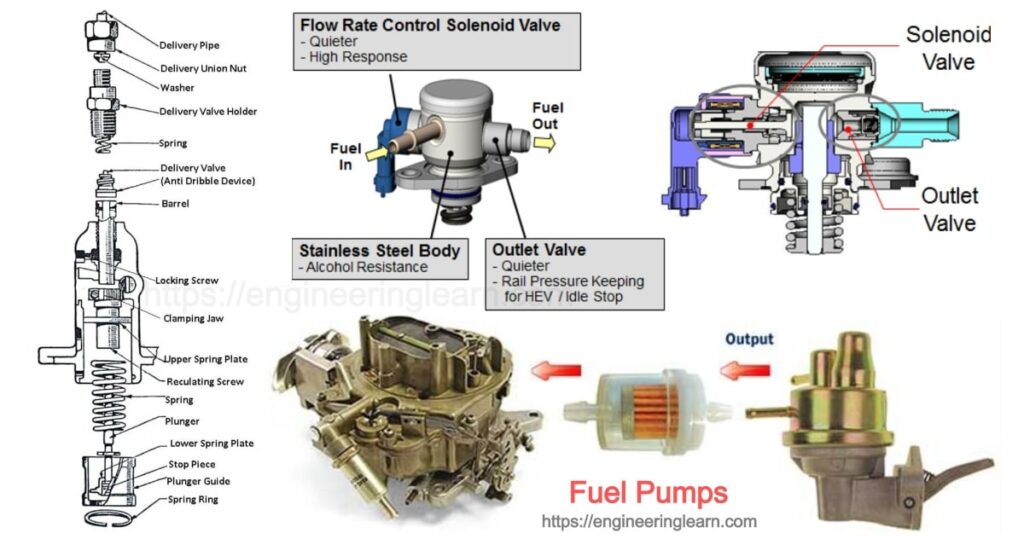

Types of Fuel Pumps: Mechanical, Electric & High Pressure Fuel Pump :- Fuel pump is fluid handling pump which transfers the fuel from fuel tank to the engine. It is generally used in the internal combustion engines. In the spark ignition engines, the fuel pump supplies the fuel from the tank to the fuel bowl and from there the carburetor mixes the fuel with air and send it to the combustion chamber of the engine.

In combustion ignition engines the fuel pump directly supplies the fuel to the combustion chamber at very high pressure. At the time of combustion, in combustion ignition engines, the combustion chamber is already filled with the highly pressurized air. Thus, the fuel pump needs to supply the fuel to the combustion chamber at the pressure more than that of combustion chamber and ignition takes place.

Types of Fuel Pumps

There are basically three types of fuel pump available in the market, each of them is discussed below: –

1. Mechanical Fuel Pump: ( Types of Fuel Pumps )

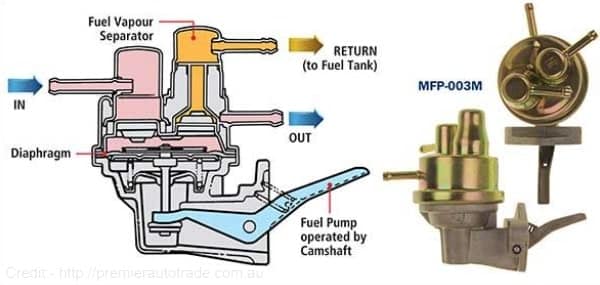

These are basically low-pressure type of fuel pumps, sometimes also used for high pressure, whose main work is to transfer the fuel from tank to the fuel bowl of the spark ignition engine. The mechanical fuel pump consists of two kind of pumps; i.e.; diaphragm type fuel pump and plunger type fuel pump.

A) Diaphragm Type Fuel Pump

The diaphragm type fuel pump is basically a positive displacement pump which sucks the fuel by expanding and contracting motion of the diaphragm. The pump body consists of inlet and outlet check valves, which are the one-way valves. As the diaphragm contracts, the pressure inside the pump become lower than the atmospheric pressure and the fuel gets sucked through the inlet valve. And, as the diaphragm expands, the fuel inside the pump pushed out through the outlet valve. The expansion and contraction motion of the diaphragm is controlled by a lever actuated by an eccentric cam motion. This eccentric cam is connected to the crankshaft of the engine through proper gearing arrangement.

B) Plunger Type Fuel Pump

The plunger type fuel pump is also a positive displacement pump which sucks and delivers the fuel by the help of reciprocating motion of the plunger. The plunger is enclosed inside a cylinder and one side of the plunger is connected with a push rod which further connects the camshaft. The valves are mounted on the end of the cylinder. As the plunger moves backward the fuel gets sucked into the cylinder and with the forward motion of the plunger fuel gets delivers out of the cylinder.

Although, the pressure of the fuel supplied from the mechanical pumps are constant but it requires proper maintenance because of lots of moving parts. These pumps are become obsolete now days because the vehicles are changed their injection system from carburetor to the fuel injection system.

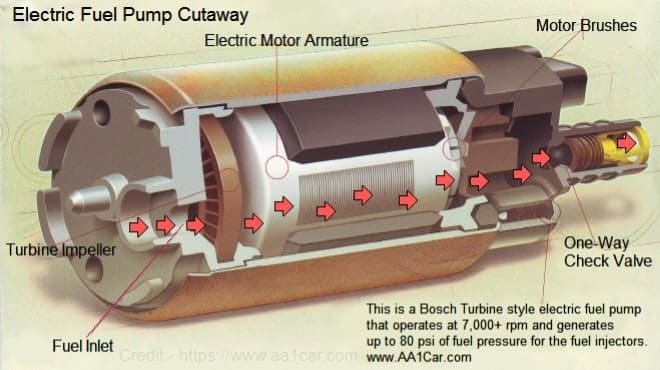

2. Electric Fuel Pump: ( Types of Fuel Pumps )

These kinds of pumps are generally used in fuel injection system, which are the essential part of the modern motor vehicles. It creates the high pressure to deliver the fuel out of the pump. This high pressure may cause the fuel to ignite inside the pump itself and be a reason of explosion. Thus, for safety purpose the electric fuel pump is kept far from the engine and more specifically, it should be kept inside the fuel tank.

The current to operate the fuel pump is supplied by the battery of the vehicle. An electronic control unit (ECU) is also available there which properly controls the output pressure and volume of the fuel and in addition, it also meters the incoming fuel from the tank. The ECU helps the vehicle to save fuel and hence gives better mileage and power. The Picture shows the configuration of electric fuel pump.

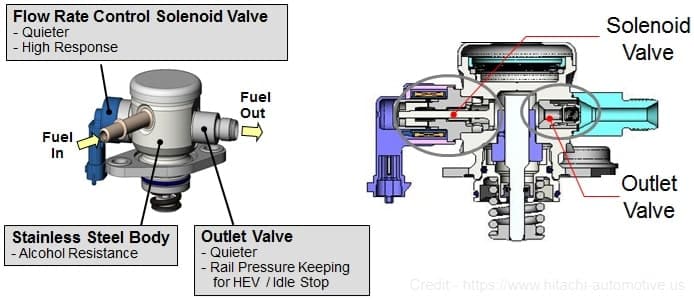

3. High Pressure Fuel Pump: ( Types of Fuel Pumps )

These pumps are generally used for the direct injection of fuel into the combustion chamber, specifically, in combustion ignition engines. These types of pumps work above 200 Pascals. To handle such a high pressure, these pump systems are made complex and sturdy. The general high pressure pump system having flow rails, metering units, distributing units etc., helps the pump to supply the fuel into the combustion chamber without any wastage or over fueling.

Working

The port and helix type high pressure fuel pump, is the most commonly used pump for combustion ignition engines. This pump is more or less similar to the radial piston pump except instead of piston it uses plunger without sealings. As, the plunger moves backward the fuel gets sucked and the forward motion of plunger delivers the fuel at very high pressure. It consists of combination of upper and lower helixes which help the plunger to get the forward motion, the backward motion is provided by the spring mounted at the top dead center of the plunger. The amount of fuel is metered by the rack and pinion arrangement, that rotates the plunger and increase or decrease the suction volume of fuel according to the need. Instead of valves, this type of fuel pump uses inlet outlet ports which are on the opposite side walls of the pump cylinder.

The high-pressure fuel pump has the following sub category, which is the centrifugal turbo pump and axial turbo pump. Apart from the port and helix type fuel pump there is another high-pressure fuel pump, i.e.; turbopump. These pumps are combination of rotodynamic pumps and driving gas turbine. These pumps are mainly used to pump the high propellants in to the combustion chamber of huge engines of rockets and spacecrafts. There are two kinds of turbopumps used for the purpose.

Difference between Centrifugal Pump and Axial Flow Pump

Centrifugal pump, which increases the pressure by throwing fluid outward through its blades at high speed, and the another one is Axial flow pump which includes an alternate arrangement of rotating and static aerodynamic blades to increase the pressure of the propellant.

The Picture depicts the centrifugal turbopump and axial turbopump. The centrifugal turbopump is far more powerful and can easily handle high density fuels but requires large space area, whereas, the axial turbopump have small space area but can handle low density fluids for the moderate pressure rise.

Image Source :- jasoceania, gapgeophysics, hitachi-automotive, aa1car