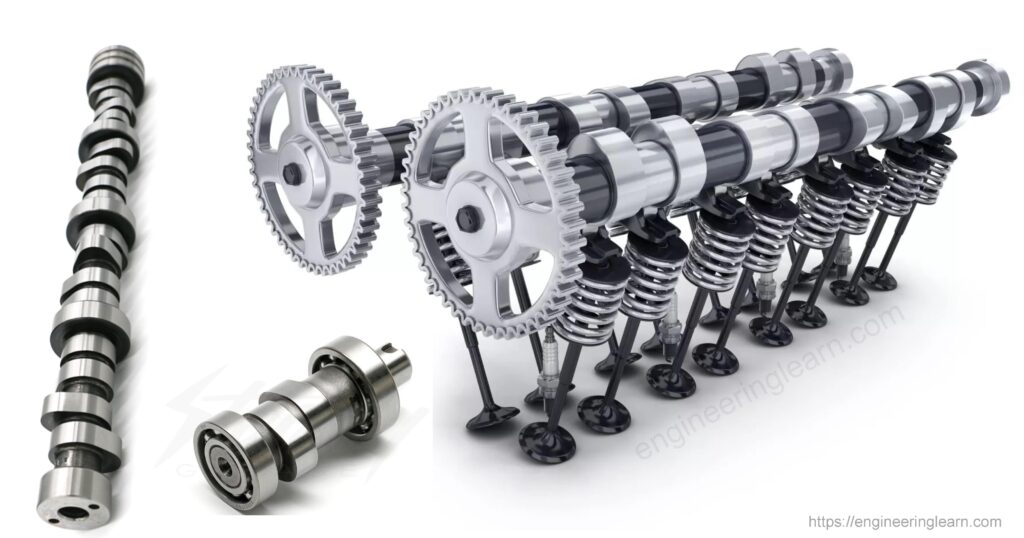

Camshaft Working and Types [Complete Details]

Camshaft Working and Types:– A Cam may be defined as a machine element with curved outline which by its motion (oscillation or rotation) provide motion to another element called the follower.

- A cam is a rotating mechanical member used for transmitting the energy to another element (follower) by direct contact. Cam of the camshaft may be reciprocating (means part of a machine moving backwards and forward in the straight line), rotating or oscillating.

- Cam mechanism are extensively used in operation of many classes of machines such as for operating valves in internal combustion engines, in primary machinery, gear cutting machines etc.

Camshaft Principal

- The camshaft uses the lobes (called cams) that are used for pushing against the valve to open them as camshaft rotates; spring on the valves return to their closed position.

Camshaft Material

- The installed camshafts are mainly constructed of modular cast iron and are induction hardened (induction hardened is surface hardening of steel & other alloy components. The part to be heat traced are placed inside a copper coil and then heated above their transformation temperature by applying to the alternating current to the coil) for preventing wear and tears. Other options are steel, stainless steel, brass and bronze.

The core production region of camshaft in the world are Detroit, Frankfurt, shanghai & Singapore.

Camshaft Working

Camshaft is the most critical and important part of internal combustion engine. Its main function is to control the valves timing, thereby allowing intake valve to open at the right time for feeding air and fuel mixture into the engine. Camshafts are basically lobes which are fitted in the engine of vehicle for giving exhaust enough time to release or escape out of combustion space.

Types of Camshaft

there are generally two types of the camshaft exist in the category; flat tappet and roller cams within these categories there are further two options are solid and hydraulic. Further there are four variation in all.

- Flat tappet cam: lobe is highly indicated at the peak lift. A flat tappet camshaft is setup where lobe and lifter ride against each other where the lifter spins on the cam lobe. the lifter must spin to the lobe to prevent destructive and unnecessary wear.

- Roller cams: nose of the roller cams are rounded which means roller is holding the valve open at higher lift for more period of time, due to which having impact in fuel/air charge demand. The lobe shape also opens the valve much faster.

Difference between solid and hydraulic camshaft

Solid lifter cams can be good option for racing engine. They usually equipped with faster lobes than hydraulic camshafts but not fast as roller camshaft. They also need shouter springs than the hydraulic cams, but not nearly as stiff as roller cams.

ADVANCING/ RETARDATION

These both processes can be done by changing the alignment of camshaft with the help of timing belt. Both processes having advantages and disadvantage too are following :

- ADVANCE CAMSHAFT:

- Open the valve sooner.

- Decrease piston to intake valve clearance.

- Decrease piston to exhaust valve clearance.

- Build low end torque.

- RETARD CAMSHAFT:

- Open the valve sooner.

- Build higher end torque (more).

- Decrease piston to intake valve clearance

- Decrease piston to exhaust valve clearance