Indirect Fuel Injection: Working, Advantages, History & Diesel Fuel Injection [Complete Details]

What is Indirect Fuel Injection?

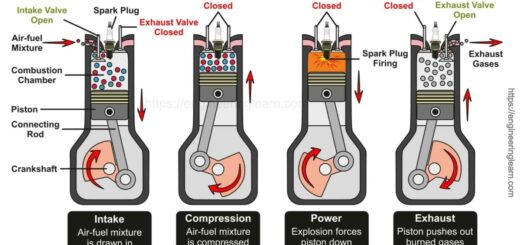

Indirect Fuel Injection: – This type of fuel injection system is employed in Petrol-engine cars wherein a fuel pump sends the fuel to the bay of the engine then it’s injected into the manifold using an injector. So, there is either a special injector for each cylinder or one or two injectors into the manifold. The fuel or air mixture is controlled by the carburetor, which is not in the least perfect by any means.

This is the main demerit which states that one carburetor supplies a four- cylinder engine which cannot give each cylinder an equivalent fuel-air mixture accurately as a number of the cylinders are distant from the carburetor as compared to others. So, the answer to the present problem is to suit twin-carburetors which are again difficult to tune correctly. Rather, various cars are being fitted with fuel-injected engines where the fuel is delivered in accurate bursts. The engine is provided in such a fashion to form it more efficient and powerful as compared to the carbureted ones as they will even be more economical and fewer poisonous.

Diesel Fuel Injection

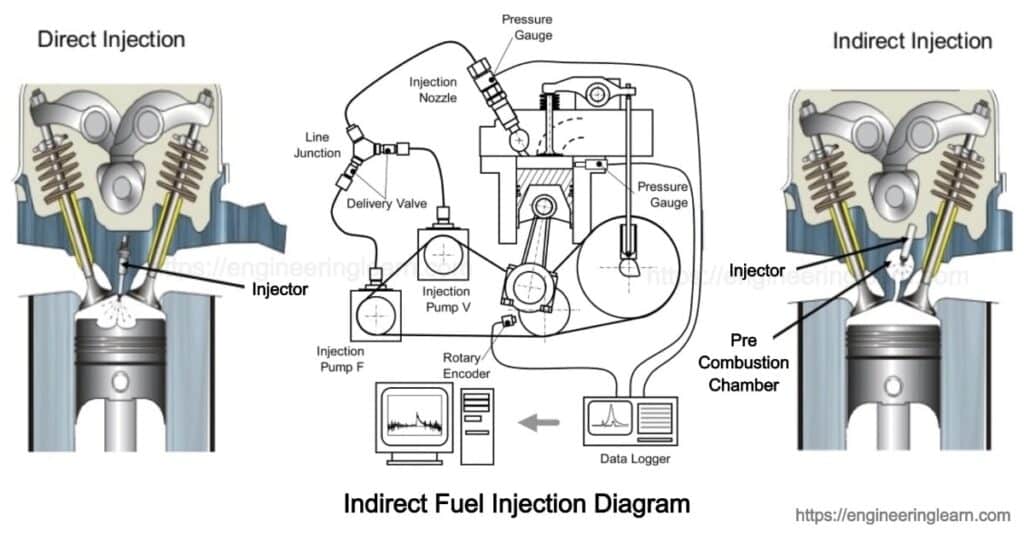

The fuel injection system which is used in a petrol engine car is always indirect where the petrol is injected into the inlet manifold or inlet port before directly moving it into the combustion chamber. This makes sure that the fuel is mixed properly with the air before it enters into the chamber.

However, there are diesel engines which use direct injection during which the diesel is injected directly into the cylinder which is crammed with the compressed gas. The injection system aside from diesel oil injection uses indirect injection during which diesel is injected into the pre-combustion chamber which is specially shaped and features a narrow passage which connects it to the top of the cylinder.

Basic injection

A special pump is present which sends the fuel struggling from the fuel tank to the engine bay where it still faces pressure and it is distributed individually to every cylinder. The fuel is squirted into either manifold or the inlet port with the assistance of an injector. This technique works like a sort of spray nozzle of a hose, which ensures the fuel beginning as a fine mist. The fuel get mixed with the air which passes through the manifold or port and therefore the fuel-air mixture enters into the combustion chamber.

There are various points of fuel injection system where the each cylinder is fed by its own injector. This becomes complex and may be expensive too. It is more common to possess single-point injection where one injector feeds the entire cylinder.

Injector

The injector refers to as those through which the fuel is sprayed and screwed either into the manifold or within the plate. It is set at an angle in such a way that the spray of the fuel is fired towards the inlet valve.

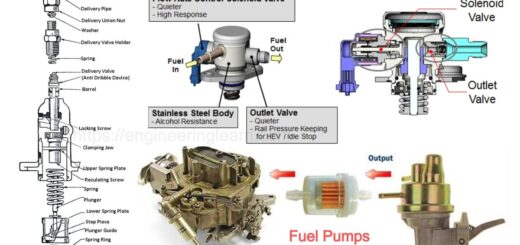

The injectors also are of two types which depends upon the injection system within the first system, there is an endless injection where the fuel is sprayed into the inlet port while the engine is running. The injector works as a nozzle spray which breaks up the fuel into a precipitation which does not control the flow of the fuel. The quantity of fuel which is sprayed, increases or decreases by a mechanical or electrical control unit which is simply like an on or off.

The other system which is common is the pulse injection system where the fuel is directly delivered in the bursts to coincide with the induction stroke of the cylinder. This injection can be controlled by injecting it continuously either mechanically or electronically.

The ancient systems were totally controlled mechanically and were often called petrol injection or (PI) whereas the fuel flow in this system is controlled by a mechanical regulator assembly. The drawback of this system is that being quite complex mechanically, it has a poor response towards backing off the throttle. Mechanical systems have been largely taken up by the electronic fuel injection (EFI).

Working of Fuel Injector

The fuel is pumped at a really high from the fuel tank to the fuel accumulator. Then, it passes to the fuel distributor, which shifts the burst of fuel to each injector, then after it is fired into the inlet port. The flow of air is controlled by the flap valve which opens to react to the accelerator pedal.

Whenever the flow of air increases, the fuel distributor increases the flow of fuel automatically to keep the fuel-air mixture balanced. A choke on the dash or on later models or a microprocessor control unit brings a special cold-start injector into operation, which injects extra fuel to make an ideal mixture. Once the engine undergoes the warm up to a specific temperature, then a thermo switch automatically cuts off the injector of the cold-start.

History of Fuel Injector

First mechanical fuel injection was used in the year 1960 and 1970 by various manufacturers on their higher-performance of sports cars. A very high-pressure electric fuel pump was mounted near the fuel tank which fuels at a pressure of 100 psi up to a fuel accumulator.

It is basically a sort of short-term reservoir which keeps the pressure of the fuel-supply constant and also irons out the pulses of fuel which come up from the pump. From the accumulator, the fuel gets passed through a paper element which feeds into the control unit of the fuel-meter which is known as the fuel distributor. This unit is then driven from the camshaft and its job is same as the name suggests. It distributes the fuel to each and every cylinder at the right time and in the accurate amount.

The amount of fuel which is injected is controlled by a flap valve which is located in the air intake of the engine. The flap is set below the control unit which rises and falls the response to airflow whenever the throttle will suck from the cylinder it will definitely increase the flow of air and the flap up rises.