Slotting Machine: Definition, Parts, Types, Operation, Application, Advantages & Disadvantages

What is a Slotting Machine?

Slotting Machine: Definition, Parts, Types, Operation, Application, Advantages & Disadvantages :- Slotting machines are the reciprocating machine tools which are generally used to produce slots or keyways in the flat or cylindrical surface. It is similar to the vertical shaping machine in which the tool reciprocates in vertical direction. Both slotting machine and vertical shaper operates on the same principle such that ram holding the tool reciprocates and by this motion tool machine away the work-piece in forward direction only, whereas the backward direction is ideal and no machining action takes place during this motion.

Moreover, the ram of vertical shaper can swivel to certain angle with respect to horizontal axis and not more than 5o with respect to vertical axis, but this swivel movement is not possible in slotting machine.

The tool used in slotter machine is basically a single point tool cutting tool generally made of high speed steel (HSS) or tool steel with carbide insert tip. The slotting machine is used to machine grooves, keyways, slots of various shapes, internal and external gear cutting etc. processes. A slotter can be useful in any type of machining where the vertical tool movement is required and considered advantageous for the purpose.

Operation of Slotting Machine

The slotter machine works on the principle “work-piece remains stationary and tool reciprocates” and “The machining will occur only in forward motion whereas the backward motion is ideal”. The reciprocation of the tool along with the ram works on the quick return motion mechanism (QRMM). As the name says, the QRMM is a mechanism through which the returning motion, backward movement, of the tool is quicker than that of forward motion.

The QRMM gets power from the main high power electric motor through gear or pulley assembly. The feed, during the cutting operation, is given to the work table through pawl & ratchet mechanism.

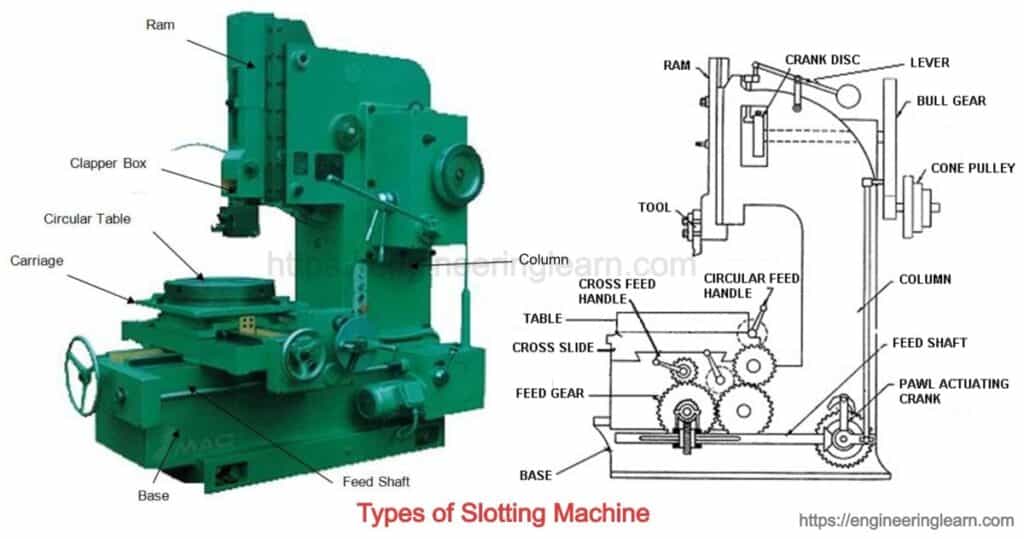

Parts of Slotting Machine

The parts of a slotting machines are described below;

1. Base

The base is the sturdy part of the machine which takes up all the cutting forces, vibrations and entire load of the machine. It is made from cast iron.

2. Column

The right rigid vertical part of the machine is the column. It houses the reciprocation and feed mechanisms. Apart from this it also bears the machining loads during the machining operation.

3. Ram

Ram provides the reciprocation motion to the tool. Ram reciprocates in the guide ways made in front of the column. The ram also consists of a tool post, where the cutting tool is made to be fixed.

4. Work Table

The work table is the place where the machining operation takes place. The work-piece is made to fix on the work table so that the tool can perform the machining operation accurately. The table can be either magnetic type or manual slotted type. The shape of table can be circular or rectangular. The table has only one sliding motion, either in X-direction or in Y-direction, and mounted over the cross slide.

5. Saddle-Table & Cross Slide

he saddle-table fits over the base of the machine with the help of guide ways. It provides the motion in Z-direction. The cross slide is mounted upon the saddle and have another in-plane motion apart from the table motion.

6. Reciprocating Mechanism

There are basically two type of reciprocating mechanism used in the slotting machine; mechanical mechanism and electrical mechanism. The mechanical mechanism is of two types, Whitworth’s QRMM, and the hydraulic drive mechanism. The QRMM is combination of different links which transfers and modifies the motion and power given to them. The hydraulic drive operates on the pressure of fluid, and hence, this drive gives more accurate and effective control over the ram motion.

The electrical mechanism consists of variable speed reversible motor drive. The electrical mechanism is the best amongst all the aforementioned three kind of drive because it gives more accurate and controlled movement of ram compared to the rest two.

7. Feed Mechanism

In a slotting machine the feed is generally given by hand by giving different movement to the work table. But, the power feed (automatic feed) is also available in the slotting machine. The automatic feed consists of pawl and ratchet mechanism.

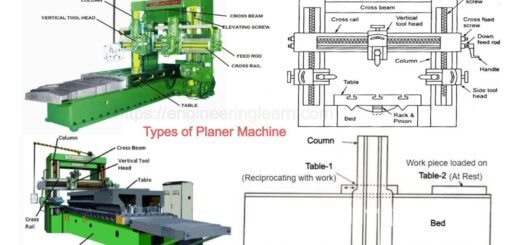

Types of Slotting Machine

1. Puncher Type Slotting Machine

It is a rigid and heavy duty slotting machine which is design to removing a large volume of metal from castings and forgings. The stroke length of the puncher slotting machine is quite large so that it can cover a wide area of the work piece to be machined.

2. Tool Room Type Slotting Machine

This is a light weight slotting machine is generally used in tool room for the training and tool designing purpose. It operates at high speed and gives accurate and good surface finish.

3. Production Type Slotting Machine

It is a heavy duty slotting machine used for the heavy duty machining operation. It is generally used for the general production work.

4. Keyway Type Slotting Machine

It is a special purpose machine which is used to produce the special keyways in the work piece.

Application of Slotting Machines

- It is generally used to cut keys, slots, grooves of various shape and size. It is advantageous to the applications where the vertical tool movement is necessary for the manufacturing process.

- It is used to create inside keyways, splines etc., over cylindrical, concave or convex surfaces.

- It is also used for machining and manufacturing of internal and external gears.

- Enlargement and finishing of noncircular holes.

- Machining of internal flat surfaces.

Advantages of Slotting Machines

- Low initial cost

- Low maintenance cost

- Accurate in surface finish

- Light weight and durable

- Single point cutting tool makes the tool cost cheaper

- High machining efficiency

Disadvantages of Slotting Machines

- Skilled labour is required to operate the machine

- The design of machine is rigid.