7 Parts of Piston and Their Functions [Complete Guide]

![7 Parts of Piston and Their Functions [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2023/08/Parts-of-Piston-1024x539.jpg)

Introduction

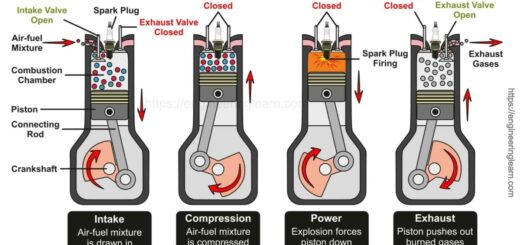

7 Parts of Piston and Their Functions [Complete Guide]: – In an internal combustion engine, a piston is perhaps one of the best parts that assist the working of the combustion cycle. The engine part is enclosed or encased in a cylinder block which uses a piston ring to give no space for gas to escape. The piston assists in the transformation or change of heat energy into mechanical work as well as the other way around. It moves up and descending inside the cylinder in order to expand and contract the air-fuel combination.

What is a Piston?

The Piston is a moving part or piece of the combustion chamber. It is responsible for changing over (converting) the energy which is released during the combustion process and converted into mechanical work. Your piston should have high reliability and flexibility, however its weight should be as low as possible. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft by means of a piston rod or connecting rod.

The piston is connected or associated with a connecting rod, which is then connected to the crankshaft. Together, the piston, connected rod, and crankshaft convert the all-over movement of the piston into the rotational movement that controls the wheels of the vehicle. It is made of hardened steel and is fixed in the piston with the assistance of circlips yet it can uninhibitedly move in the connecting rod.

Below is the process of piston which is accomplished in three ways:

- Providing heat to the gas inside the cylinder for the valuable work

- Eliminating heat from the cylinder to diminish the pressure, with the goal that the gas can undoubtedly be compressed.

- Once more apply work to the piston when it’s in its underlying or initial state, prepared to play out the cycle.

Parts of Piston

- Piston Rings

- Piston Pin

- Piston Skirt

- Piston Head

- Connecting Rod

- Piston Bearings

- Connecting Rod Bolt

Piston parts work together for the transformation of heat energy into mechanical work as well as the other way around. It moves up and downward inside the cylinder to grow and expands air fuel combination. The basic structure of the piston is a hollow cylinder, which is closed on one side, with the segments piston crown with ring belt, pin boss, and skirt.

1. Piston Rings

Piston rings are the bits of split rings that are mounted on a recess area of the piston. There are generally three piston rings in an engine. Now and again the ring can be one, contingent upon the engine type. The essential function of a piston ring is to close the combustion chamber and control lubricating oil use. The rings additionally help to convey heat away to the cylinder bore.

(A) Oil Ring

An oil ring is the piston ring located in the ring groove nearest to the crankcase. The oil ring is utilized to clear excess oil from the cylinder wall during piston movement. Excess oil is returned through ring openings to the oil repository in the engine block.

(B) Wiper Ring

The wiper ring likewise called a Napier ring, or backup compression ring, are installed beneath the compression ring.The primary reason you really want to pick to utilize a wiper ring is to prevent residue and debris from going into the housing of your sealing system. One of the main considerations while picking a wiper ring is the material that it’s made from. When picking the right material for your wiper seal thinking about natural circumstances is significant. Wiper ring provides a precise sense of finality and a reliable seal to safeguard against dirt and residue, while as yet permitting back-flow of residual oil film.

(C) Compression Ring

This is the top side ring and is closest to the combustion chamber. It is likewise called the gas or pressure ring. The ring forestalls combustion gases from leaking or spilling. Compression rings likewise assist with transferring heat from the piston to the walls of the cylinder.

2. Piston Pin / Gudgeon Pin

It tends to be fitted to the skirt of the piston and allowed to float and pivot, to restrict hub development. The Gudgeon pin should be positioned comparative with the piston so it doesn’t rub against or damage the cylinder. The Piston pin is a piston part that is otherwise called a wrist pin or Gudgeon pin. This pin is the hollow or solid shaft in the skirt segment. Piston pins are created from alloy steel to offer a decent tensile strength. It looks practically equivalent to a simple cylindrical shaft, which can be solid or hollow. The pin might be liable to high loads in alternating demands because of the oscillating motion of the piston, gas interaction, and inertial forces.

There are three kinds of piston pins out there: –

(A) Stationery/Fixed Pin

The pin attaches or joins to the bosses of the piston by means of a screw. The piston rod then pivots or turns on the pin.

(B) Semi-Floating

The pin joins or appends to the interfacing or connecting rod in the middle, and the pin ends move uninhibitedly within the piston bearing and at the bosses.

(C) Full-Floating

In this pin type, the pin isn’t attached or joined to the pin or piston connecting rod. Taking everything into account, it is secured by plugs, clips, or snap rings attached or joined to the piston bosses. The pin can then sway at the bosses as well as the rod.

3. Piston Skirt

The skirt of a piston suggests the cylindrical material mounted on the round portion of a piston. The part is typically made of cast iron because of its incredible wear resistance and self-lubricating properties. The skirt contains the grooves for mounting the piston oil ring as well as compression rings. Piston skirts are accessible in various designs to meet explicit applications.

There are two main types of piston skirts: –

(A) Shoe Skirt

The sort of piston skirt utilized for the pistons of motorcycles and a few automobiles. A part of the skirt is removed with the goal that only the back and front surfaces stay on the cylinder wall. This assists with reducing weight and limits the contact area between the cylinder wall and the piston.

(B) Full Skirt

It is otherwise called a solid skirt. The full skirt is tubular or cylindrical in shape. It is generally utilized in the engines of large automobiles.

4. Piston Head

This part of a piston is otherwise called a crown or dome, which is the top surface. The part contacts the combustion or burning gases, making it experience a very high temperature. To be sure, the piston is made with extraordinary alloys, for instance, a steel alloy that can withstand the temperature and forestall it from melting. The functional capability of the piston is to receive pressures, temperatures, and different stresses of the expanding gas. The piston head in like manner fills various purposes, for instance, creating swirl to make combustion uniform and knocking guideline.

The Piston head goes about as a heat barrier between the combustion chamber and the lower piston parts. Pistons are accessible in various types suitable for a particular type of engine. There are many factors that determine the design of a piston head, for example, the type of engine and required performance.

5. Connecting Rod

A connecting rod is one of the significant parts of a piston most time shortened as a conrod or rod. It connects or associates the piston to the engine’s crankshaft and permits the piston’s movement in the chamber. The part is designed to bear mechanical strain which is the reason it’s sufficiently durable. The piston parts are made from forging and now and again casting process. Most piston out there is made of steel as it’s suitable for superior performance engines. Aluminum is utilized when a lighter-weight piston is needed for milder engines.

The functional capability of the connecting rod is to rotate or pivot the crankshaft which produces motion that permits the engine to move. This rod contains a bored hole or opening that delivers or conveys lubricating oil to the cylinder wall as well as a wrist pin.

Connecting or Interfacing rod is of different design which incorporates milled joint, crack joint, straight and angled separation rod as well as parallel and tapered rod design.

There are various parts in a connecting rod which are mentioned below: –

(A) Small End

The smallest end of the rod comprise rod eye and piston bushing. This small end connects to the piston through a piston pin.

(B) Big End

The part is opposite or inverse to the small end of the rod. It’s connected or associated with the crankshaft.

(C) Connecting Rod Beam

Connecting rod beam is a part that is between the small and big parts of the rod. It is normally a twofold T construction and could possibly contain an oil passage to convey oil onto the cylinder.

6. Piston Bearings

The bearings are great piston parts that help the effectiveness of the movement. It’s located at the points the pivotal rotation happens. The bearings serve to reduce friction and allow smoother rotation. This eliminates the amount of energy consumption or utilization. These bearings are commonly semi-circular metal pieces that fit in the bores of these points. Shells in the big end where the rod is connected or associated with the crankshaft are part of the piston’s bearing. The part is frequently manufactured from metals like copper, silicon aluminum, and so forth. It is additionally coated to enhance hardness and empower them to withstand the load of the piston and the connecting movements.

7. Connecting Rod Bolt

One more piston part that can’t be left behind is the conrod bolt. Mounting the rod to the crankshaft is utilized. There is a rod caps and bearing at the base end of the rod bolts. A nut is then used to lock or secure the parts along with the bolt. The bolt is made using steel, yet aluminum is utilized when a lighter-weight part is needed. Nickel is likewise utilized when the stronger rod is required which is in many cases time required in heavy-duty vehicles.

The functional capability of the bolts is to secure the connecting or associating rod to the crankshaft, assisting the rod with enduring the strain brought about by the rotating crankshaft. The rod would break and influence the working of the engine parts assuming the bolt is excluded.

Conclusion

Having looked at the piston parts above, you presently know what every part looks like as well as its location on the piston assembly. The piston ought to be all around as strong as could really be possible, notwithstanding, its weight ought to be limited as far as possible because of its reciprocating mass. However, there are a few issues related to the piston in the event that not changed or replaced quickly. The problem piston develops isn’t anything nothing less than a crack. This crack happens on the top of a piston head which is known as a crown. It is normally brought about by excessive compression or over- advanced ignition timing because of combustion pressure in petroleum engines.

Piston gives a serious level of maneuverability and furthermore has less manufacturing costs because of large-scale productions. Pistons are made using either low-carbon steels or aluminum alloys. The piston is subjected to high heat and intensity, inertia, vibration, as well as friction. Carbon steel limits the effects of differential thermal expansion between the piston and chamber walls.

Image Source: – gesrepair