What is Crane? Types of Cranes and Their Uses in Construction [with Pictures & Names]

![What is Crane? Types of Cranes and Their Uses in Construction [with Pictures & Names]](https://engineeringlearn.com/wp-content/uploads/2022/08/Crane-1024x539.jpg)

Introduction

What is Crane? Types of Cranes and Their Uses in Construction [with Pictures & Names]: – It’s astounding to see the various kinds of machinery and heavy equipment in operation when you enter a building site. A crane with its boom or mast raised in the air while transporting or lifting a load is frequently the first thing you notice.

Whether you’re new to the business, or a carefully prepared veteran, there’s a decent opportunity that you’ve experienced crane hardware that you haven’t seen, or you’ve heard a crane term that you’re curious about.

In this article, we want to assist you with laying out a base-level comprehension of the various sorts of cranes, how they’re utilized, and the way that they contrast from one another. This content will make you deeply learn more about the cranes. Scroll down to learn more:

Static Cranes v/s Mobile Cranes

Cranes can be divided into two primary categories: Static cranes and mobile cranes. Static cranes hoist and transport loads along fixed paths and are permanent or semi-permanent structures fixed to the ground or building. A mobile crane is transportable from job site to job site and is mounted on treads or wheels.

Portable cranes are not confined to a proper way like a static crane. A few portable cranes are fit for a “pick and convey” capability, where they plainly get a heap and convey it to an alternate area by means of its tracks or wheels. A few versatile cranes require the utilization of outriggers, stabilizers, or even nearby get together.

Different Types of Cranes

A) Static Cranes

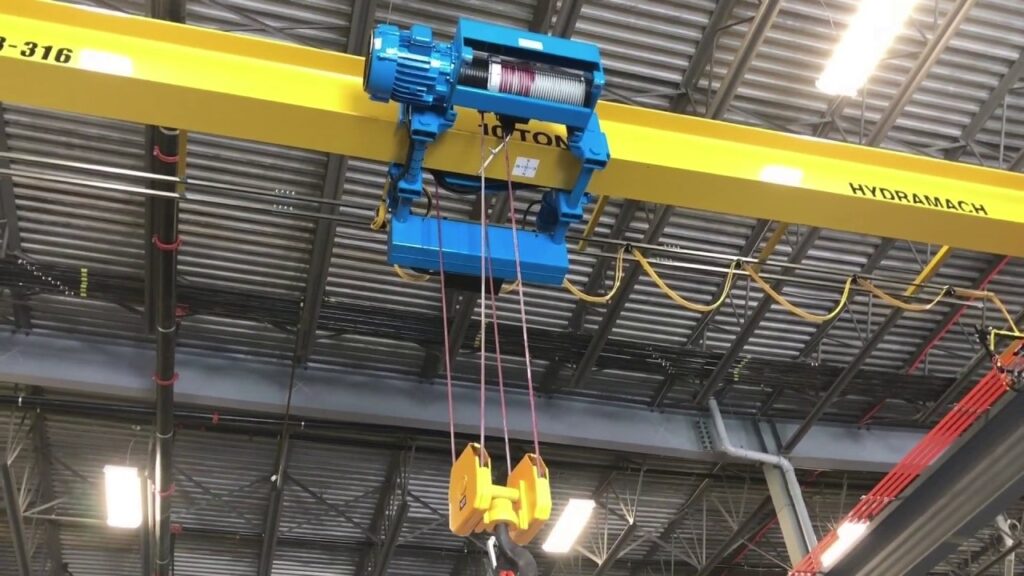

A static crane is a stationary or semi-fixed structure that is fastened to the ground or a building and can only move in one direction. An overhead bridge and a hoist that move side to side along a bridge beam are the basic parts of an overhead crane. The overhead bridge moves back and forth along a runway.

1. Overhead Cranes: ( Types of Cranes )

A horizontal beam known as the bridge is moved up and down a runway on an overhead crane by a track or rail. To lift and lower items across a rectangular bay, a trolley and hoist move side to side along the bridge. These cranes have different load limitations ranging from.25 to 400 tonnes and are used to promote safety and efficiency within a warehouse or facility.

The fundamental method for distinguishing an above crane is that it’s precisely exact thing it seems like, above the shaft drops evenly all over the place a runway over an office or building site along a proper way.

When built for repetitive process use at plants or construction sites, overhead cranes are typically permanent fixtures. Bridge cranes are the overhead cranes that are most frequently mentioned, although there are other types as well, such as:

- Bridge crane

- Gantry crane

- Monorail crane

- Jib crane

- Workstation crane

2. Tower Cranes: ( Types of Cranes )

Tower cranes are referred to as those cranes which are usually found in the city horizons, and which are found being utilized for the purpose of constructing tall designs like high rises. The fundamental parts of a pinnacle crane are an upward tower otherwise called a pole and an outstretched jib.

The jib travels along the trolley and hook block and can turn 360 degrees around the mast (this motion is called slewing). These cranes are frequently put together by smaller, portable cranes.

There are three different types of tower cranes:

- Hammerhead cranes

- Luffing tower cranes

- Self-erecting tower cranes

(i) Hammerhead Tower Crane

On a hammerhead tower crane, the jib pivots 360 degrees evenly around the pole at a proper level with the design looking like a topsy turvy “L.”

This kind of tower crane can do racking, which is when the trolley moves the weight along the jib horizontally without changing its level.

Hammerhead tower cranes are sometimes referred to as “A-frame” tower cranes or flat-topped/topless tower cranes. The presence of metal work (with a “A”-like shape) above the crane linking the jib to the counter jib distinguishes an A-frame from a topless tower crane.

The reason for a level top crane is to be utilized in circumstances with low head-room or where various cranes may slew under or over each other. Before, the disadvantage to level top cranes was their failure to lift equivalent abilities to that of A-outline crane.

(ii) Luffing Tower Cranes

Luffing Tower Cranes are one of the many types of cranes used in construction. A luffing-jib crane is another name for a luffing tower crane. The jib is latticed and may be lifted and lowered, an action known as “luffing,” and its construction is comparable to a hammerhead tower crane.

These cranes can Lift more weights than hammerhead cranes have more jib motion;

are more costly due to its smaller slewing radius, are especially suitable for work in crowded situations and/or with several cranes.

(iii) Self-Erecting Tower Cranes (SETC)

Self-raising pinnacle cranes incorporate a flat jib and pole mounted to a counterweight and can crease and unfurl for destroying and erection on location.

SETCs are generally pertinent to conditions where:

• Development requires a tight fit between structures

• Very weighty lifts are not needed

• There is regular erection, destroying, and transportation of hardware

3. Level-Luffing Cranes: ( Types of Cranes )

A rotating, latticed jib attached to a vertical mast that slews and slides inward and outward from the base makes up a level-luffing crane.

The mechanism for keeping the hook level while moving the jib up and down is the inward and outward jib movement specific to these cranes. Due of this, these cranes are very helpful when safely lifting and transferring goods that are close to the ground.

The jib itself slides inside and outward to move into place for lifting and lowering the load rather than a trolley and hook block moving along it. These cranes are frequently employed in shipbuilding, loading freight, and construction.

B) Mobile Cranes

Portable cranes comprise of an outstretched blast frequently alluded to as a cross section or adaptive blast mounted to a truck or other versatile design that movements through tracks or tires. The blast can pivot up to 360 degrees and reach out to differing lengths relying upon the kind and size of the crane. These kinds of cranes are not limited to a proper way and can move all through a building site or potentially between locales.

The legality of a mobile crane for use on public roads will depend on its type. This is how some sources define a mobile crane, whereas others define it as any crane mounted to a mobile vehicle with an engine.

1. Crawler Cranes: ( Types of Cranes )

Crawler cranes, likewise alluded to as grid cranes, blast cross section cranes, grid crawlers, adaptive crawlers, and so forth – are the biggest of the versatile cranes. These are substantial cranes that use “tank-like” tracks to move all through a building site and can lift more than 2500 tons.

Of all mobile cranes, crawler cranes have the greatest lifting capacity and need the most on-site assembly. Onsite assembly may consist of: Depending on the size of the crane and the weight of the goods it is meant to lift,

- Connecting the tracks

- Gathering the grid blast

- Expansion of stabilizers

Crawler cranes don’t need the utilization of outriggers as the tracks give sufficient soundness. Because of their broad on location gathering, enormous size, and tracks, crawler cranes are not street legitimate.

A telescoping boom or a lattice boom may be used by crawler cranes. When compared to those who use telescopic booms, those who use lattice booms can move heavier capacities at greater heights and farther distances.

2. Rough Terrain Cranes: ( Types of Cranes )

Harsh territory cranes, otherwise called “RT” cranes, are a kind of versatile crane planned explicitly for “going mud romping” in testing conditions that might incorporate mud, snow, and so on.

For pick and carry activities up to 165 tonnes, rough terrain cranes with four tyres and a telescopic boom are used. They are useful for moving through and lifting in limited spaces because of their small frame. When a crawler crane is appropriate but has a lower load capacity or requires manoeuvring in limited locations, RT cranes are frequently used.

Since RT cranes are mounted on an underside with tires, they are handily set up and moved from one site to another, yet are not street legitimate. These cranes are worked from a taxi, which turns over the underside couple with the blast’s development. Their on location gathering necessities incorporate settling the crane for lifting with the utilization of outriggers.

3. All-Terrain Cranes: ( Types of Cranes )

An all-terrain crane is a particular kind of mobile truck crane that can move both on and off-road surfaces, including at high speeds on the highway. These cranes have anywhere from 4 to 18 tyres, similar to a giant truck, depending on the size of the crane.

An adaptive blast mounted onto the bed of the truck is utilized to lift and move loads. Off-road cranes can lift considerably more than an unpleasant territory crane can at limits as much as 1200 tons yet are less fit for exploring in outrageous conditions or in bound regions.

A cab that rotates over the truck bed in unison with the movement of the boom controls all-terrain cranes. The crane needs some on-site assembly since outriggers steady it and counterweights keep it balanced.

4. Truck Cranes: ( Types of Cranes )

The terms truck crane, blast endlessly truck mounted crane (TMC), are utilized conversely. Truck cranes are a sort of portable crane made of a blast mounted to a truck bed and are, in this manner, street lawful. Truck cranes are more modest, less adaptable, and utilized for lifting lighter burdens (load limit cutoff of around 45 tons).

5. Carry Deck Cranes: ( Types of Cranes )

A carry deck crane comprises of a compact, flat platform with four wheels and a spinning, telescopic boom. These cranes typically hoist loads weighing between 4 and 10 tonnes and employ outriggers. These cranes, as their name implies, transport materials across a site by lifting and loading them onto the deck.