Types of Deluge Valve: Definition, Operation, Application, Advantages & Disadvantages

Definition of Deluge Valve

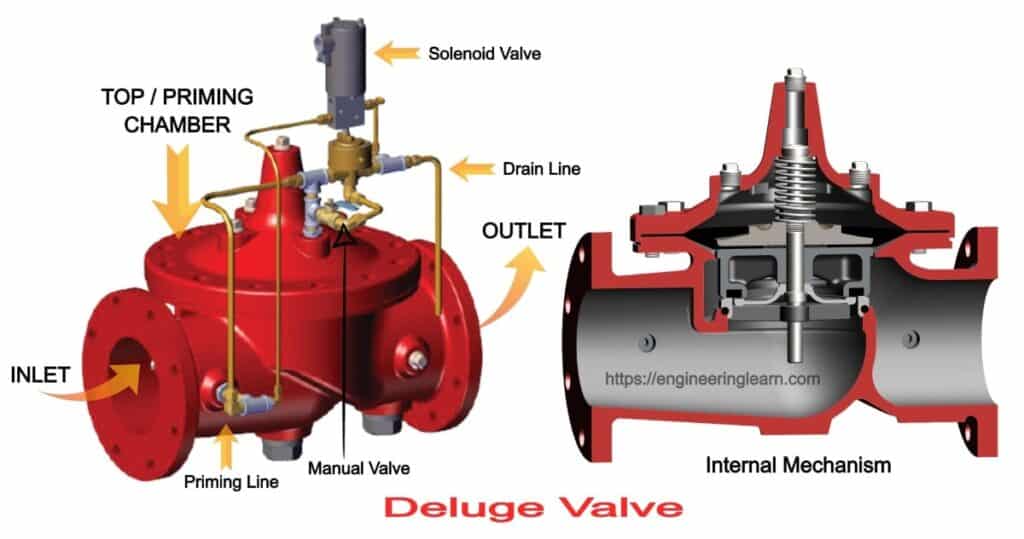

Types of Deluge Valve: Definition, Operation, Application, Advantages & Disadvantages :- Deluge Valves are used in situations when massive amounts of water must be applied quickly, and are therefore frequently seen in fire protection systems. Therefore, the proper functioning of deluge valves is very essential. Deluge systems distribute massive amounts of water across a big area in a short amount of time. They’re frequently used in fixed fire protection systems with an empty pipe system until the deluge valve distributes pressurized water from open nozzles or sprinklers. In a spray system, a deluge valve is used to quickly apply water. Deluge valves are used to safeguard locations such as power transformers, storage tanks, conveyors, and other industrial applications. They also protect aircraft hangers from flammable liquid fires with the addition of a foaming agent. ( Types of Valves )

Operation of Deluge Valve

For systems with competent detection systems and open nozzle pipelines, the deluge valve is suitable. The deluge valve keeps water out of the piping system until it’s needed. Pressure provided to the control chamber through a restricted priming line keeps the deluge valve closed. The water pressure is supplied through the deluge valve control chamber via a check valve and the normally closed release device in the set position.

The valve seal disc is pressed down by the pressure trapped in the valve chamber, sealing the valve and keeping the pipe dry. When the pressure from the automated release device or the manual release is released during a test or a fire, the deluge valve opens, allowing the input supply water to flow through the valve into the system pipe and the alarm devices.

Types of Deluge Valve

1. Basic Type Deluge Valve

This type of deluge valve is required regardless of release system. They have those components which needed by all installation like main drain valve, drip check valve, priming connection, pressure gauge and emergency release valve.

2. Dry Pilot Trim or Pneumatic Release Type Deluge Valve

This type of deluge valve need a pilot line of a closed sprinkler which is containing air under pressure for their operation. They need regulated dry air supply through main supply point with restricted orifice. With the top of positive drain actuator pilot line is directly connected and the bottom of the positive drain actuator are connected to top chamber of deluge valve.

Whenever the pressure of air reduces because any release device detect fire then diaphragm of positive drain actuator lifted and let the water drain which results to reduction of water pressure from the deluge valve’s top chamber and when pressure reaches to 50 percent of pressure being supplied in top chamber then the deluge valves get opened.

The positive drain will not let the deluge valve to get closed until the positive drain actuator is set manually.

3. Wet Pilot Trim or Hydraulic Release Type Deluge Valve

A pilot line of closed sprinkler is used for the operation of wet pilot trim which contains pressurized water which is supplied through upstream side of deluge valve with restricted orifice. All release lines are connected to common release line. Water pressure of the deluge valve’s top chamber reaches to 50 percent of the pressure which is supplied due to release of any release devices.

4. Electric Release Trim Type Deluge Valve

For actuating deluge valve electrically, there is a solenoid valve is provided for draining of water from deluge valve’s top chamber. For activating an electric alarm there is a pressure switch provided which help in shutting down desired equipment or for giving tripped indication to the panel.

With these there are two pressure switches are provided for monitoring fire condition and low air pressure when they are used in dry pilot air-line.

5. Test and Alarm Trim with Sprinkler Alarm

The trim was supplied to the sprinkler alarm bell and on actuation of deluge valve the alarm bells. For testing the normal operation of sprinkler alarm bell a test valve is provided.

Deluge valves are provided with remote or local resetting features.

A) Deluge Valves with Local Resetting

Generally local manual resetting option is required in standard deluge valves; an operator is required to be present physically at the valve location for resetting the valve. Actuation of the deluge valve may be hydraulic, pneumatic and electric or any combination of them like electro – hydraulic or electro – pneumatic.

B) Deluge Valves with Remote Resetting

Deluge valves with remote resetting is a new concept and the actuation provided may be remote, manual or automatically but when the resetting is manually provided it is not compulsory that an operator can reset valve only from remote location which in return is time saving and overcome the requirement of employing an operator at that dangerous environment of post fire and reduce the accidental closure risk.

Applications of Deluge Valves

Deluge valves are commonly used for oil as well as gas and power generation and are also used for various of applications:

- In transformers of power plants.

- Tunnels with spray system.

- Pulp and paper industries.

- In painting areas of car industries.

- LNG.

- Foam systems.

- Hangars.

- Tank farms.

Advantages of Deluge Valves

- Deluge valves are less expensive.

- They use water for extinguishing.

Disadvantages of Deluge Valves

- They are liable to damage sensitive equipment.

- They require long clean up time as compared to powder and gas system.

- Deluge valves requires large water reservoir for their operation.

Image Source :- processindustryforum