4 Types of Oil Pump – Definition, Function, Diagram, Working Principle [Complete Guide]

![4 Types of Oil Pump - Definition, Function, Diagram, Working Principle [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2022/05/Oil-Pump-1024x539.jpg)

Definition of Oil Pump

Types of Oil Pump – Definition, Function, Diagram, Working Principle [Complete Guide] :- The oil syphon is referred to as a mechanical device that is found being used for the purpose of a motor into direct oil for the purpose of moving parts. For instance bearings, camshafts, and cylinders are found having an application to prevent the parts from wearing out. These are the types which are referred to as one of the most important components that are likely to a motor oil framework, and it should not be damaged or worn out. Otherwise, breakdown would occur.

The elements of an oil siphon in a car include:

- Under the impact of strain, oil is found being moved to the motor’s significant components.

- Simplicity of motor oil development around the motor.

- Coordinates the development of the oil through the displays to various regions.

- Aids the arrival of hot oil to the supply’s cooler oil.

- Keeps up with nonstop oil dissemination inside the motor.

Working Principle of Oil Pump

In a motor for grease, the oil syphon is unavoidable because the need to grease it up while it’s running may emerge. The oil syphon is usually a device that is powered from the driving rod and begins syphoning oil as soon as the motor is started. Oil injectors are referred to as those which are used in some motors that do not use oil, such as two-strokes.

The oil cools before passing through the galleries to the working elements of the engine before returning to the sump. Oil seems being imbued for the walls of all the different chamber seals which is found to accompany along with the space within the chamber wherein the divider along with the chamber rings. This holds the compacted air back from moving away through the chambers, which increase the overall usefulness of the engine.

Specifically, for every 1000 revolutions per minute (rpm) that can roughly take it up to 55-65 psi, oil pressure is referred to as an engine might reach 10 psi. The pressure determined on the crankshaft journal along with the bearing is observed to be quite higher as compared to the relief valve on any type of relative pump’s that can vary from 50-60 psi setting, and then can reach to near about hundreds of psi at a time.

The oil plugs are blown out due to high oil pressure in the front or main engine. When the engine is cold, high oil pressure means very high pressure, which is caused by the engine’s design.

It causes the motor parts to start to fizzle, starting with the top portion of the motor, the cam transporter heading. As a resultant these are the ones which are found making the top regions of the body run out of oil. Low tension could produce liner/cylinder nip in the event that the cylinders have crown ejects. Low oil pressure might also cause the driving rod and accompanying pole to seize.

Low oil strain can be brought about by the followings:

- Low oil pressure is referred to as that which can be caused by a ragged or broken oil syphon or a broken strain relief valve spring.

- Insufficient oil in the motor, or there isn’t any in any other way. Major bearing that are depleted.

- Break or deterrent of the oil exhibition.

Types of Oil Pump

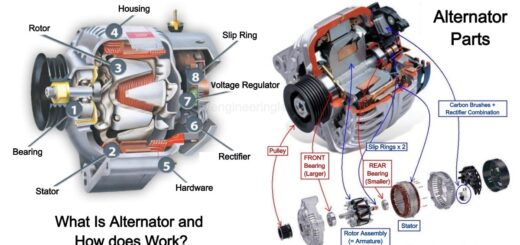

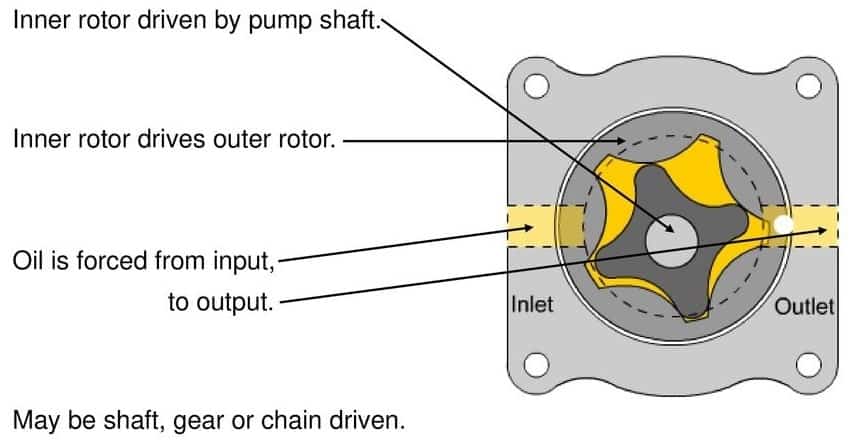

1. Rotor Oil Pump: ( Types of Oil Pump )

A rotor oil pump is referred to as a sort of oil siphon which is moreover known as a gerotor siphon. It is found containing the stuff internally where it turns from inside to outside rotor. The inward rotor features one less fold than the outer one, and it’s mounted fairly aslant of the outside rotor. This is responsible for powering up the outer rotor in order to turn the rotor to around 80% of the speed of the internal stuff.

A bellow-like pumping is found having a movement which is created for the purpose of pulling oil that can bring the input ports as well as pushing it towards the outlet port. This is known as a rotor type of oil pump which can seem to be a particularly tight tolerance to be observed being required for the purpose of optimal pumping consistency. This type of pump is found being located inside the crankcase.

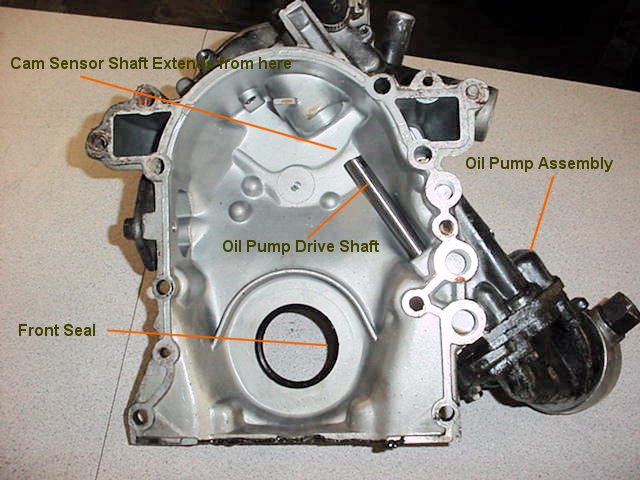

2. Front Cover Oil Pump: ( Types of Oil Pump )

The oil pump on the front cover is also referred to as an internal or exterior pump. The siphon turns at same rpm with the motor. Therefore, more tension created out of gear than a camshaft or wholesaler driven siphon. Intro page is referred to as a sort of oil siphons that can be utilized on almost all the upward cam motors which can be furthermore seen in the late model pushrod motors.

This type of condition occurs when the engine is found being cold and started first. This is responsible for slowing down the flow of oil.

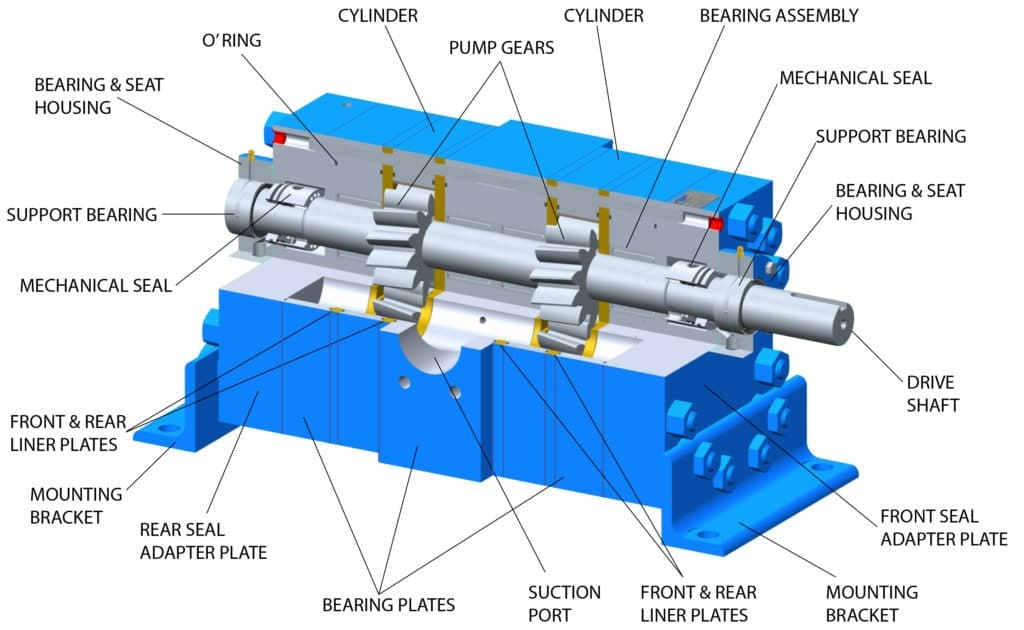

3. Twin Gear Pump: ( Types of Oil Pump )

A twin gear pump is referred to as an external pump which is referred to as that pump that can usually be known by its other name as a dual gear pump. This type of pump is referred to as the one which is found being located within the oil pan on the bottom of the engine. It pumps oil using two intermeshing gears. For instance, you must know that crankshaft, camshaft, or the distributor shafts are known to be one of the most commonly connected to the shaft that is responsible for driving the first gear.

The stuff teeth trap oil and haul it around the external stuff from the pickup tube channel to the power source.

4. Common Failure on Oil Pump: ( Types of Oil Pump )

The main function of such type of pump is to falter the oil siphon that is usually found making a sort of deep harm to the vehicle that can be most probably be at any point where the driver did not have a clue about its disappointment along with its side effects. These types of drivers are known to be the ones which are found having an issue that can happen in the motor at any moment, oil light marker on the vehicle’s dashboard turned on which ready there is an issue. The following are the disappointment side effects of an oil siphon:

Low oil pressure: This is referred to as a malfunctioning which can be a worn oil pump that is not able to pump oil along with the system very efficiently. The lower oil pressure will result in causing a potentially engine damage. Although, as indicated earlier in this post, there are various indicators of low oil pressure.

The motor will be at ordinary temperature when the siphon is in great condition as the progression of oil is steady. Whenever the progression of the motor oil is found being considered slow or stop, the parts are kept on being greased up by hot oil which isn’t permitted to stream.

Uses of Different Types of Industrial Pumps in Oil and Gas Industry

In the oil and gas business, various types of industrial pumps are used for fluid transmission. Pumps used in the oil and gas industry can be divided into six groups based on their design and construction:

- Centrifugal pumps

- Reciprocating plunger pumps

- Progressive Cavity pumps

- Gear Pumps

- Diaphragm pumps

- Metering pumps

1. Centrifugal Pumps

The most prevalent type of pump utilised in the oil and gas business is centrifugal pumps. Centrifugal pumps employ centrifugal force to draw fluid into the pump’s intake and force it through the discharge portion. Discharge flow control valves regulate the pump’s flow. Single stage radiating siphons are basically utilized for moving low-consistency liquids that require high stream rates. These pumps are found being ordinarily utilized as a component of a bigger siphon that are found including the network as well as various other radiating siphons.

2. Reciprocating Plunger Pumps

Usually the oil as well gas businesses are known to be the ones that are accompanied along with the plunger pumps and are thus the most common industrial pumps. Plunger pumps pressurise fluid in an enclosed cylinder to a pipe system using the reciprocating motion of plungers and pistons. Un-clogger siphons require more incessant support than diffusive siphons because of the plan of the moving parts. They additionally have a noisier activity than outward siphons.

3. Progressive Cavity Pumps

It directs the moment of the liquid by using various techniques like the advancement, siphon, or through an arrangement of little, fixed shape, discrete pits, as its rotor which is found being turned regularly. Moderate hole siphons are the ones which are found being used highly in most of the highly thick applications or in the events that are found mixing the siphoned liquid isn’t wanted.

The framework pressure is found having the stream rate which remains quite basically in order to maintain a consistent given speed. At higher tensions, stream slippage is normal. A help valve is a significant element of any ever-evolving pit siphon release channelling framework since it keeps the siphon and funnelling framework from over-compressing.

4. Diaphragm Pumps

Diaphragm pumps are termed to be one of the most adaptable kinds of oil and siphons in the business and move liquid through certain removal with a valve and stomach. There are various functioning guidelines of such type of siphon. One amongst this is that an abatement in terms of the volume is found causing an expansion in terms of the tension in vacuum as well as the other way around.

In oil refineries there are observed some of the diaphragm pumps which are ideally installed for the purpose of high-volume fluid transfer activities. They are found requiring a very less maintenance in terms of cost and are also compared with the positive displacement pumps as they are found having fewer moving.

On the drawback, stomach siphons are vulnerable to ‘winks’ – low-pressure conditions inside the framework that log jam siphoning activities. There can be similar type of explanation for this, you must know that they are the ones that does not be appropriate for the purpose of being ceased or for being a significant distance for siphoning the tasks as they are for the most part and do not meet the high-pressure conditions as per requirement.

5. Gear Pumps

A gear pump is found having an application of pumping the fluid by the purpose of displacing it by the use of meshing of gears. Gear pumps are found having application of transferring various industrial fluids as most of the gear pumps are found having most prevalent forms for the purpose of positive displacement in the pumps.

External gear pumps, which use two external spur gears, and timing gears, which drive the internal gear set, are the two basic varieties. External gear pumps are referred to as the ones which are found pumping all types of non-lubricating fluids as the internal gears are observed not being touched. The internal mating gear is driven by a shaft-driven driving gear in internal gear pumps. Positive displacement is also termed as a fixed displacement which is found having a gear pump attached to it for the same amount of fluid every time they turn.

Gear pumps are typically utilised for clean fluids since the pushed fluid passes between the close gear tolerances. A relief valve is an important part of the discharge piping system because it protects the pump and the piping from being over-pressurized.

6. Metering Pumps

A metering siphon ships a particular measure of fluid in a foreordained measure of time, bringing about a precise stream rate. Metering is the conveyance of liquids at accurate, controllable stream rates. The expression “metering siphon” alludes to the application or capacity of the siphon instead of the particular sort of siphon. Simplex responding siphons with a pressed unclogger or stomach fluid end make up most of metering siphons. As the siphoned liquid are the ones which are found being fixed inside the stomach, for the fluid finish in terms of stomach is being liked. There seem to be no breaks of siphoned fluid into the air.

Image Source :- slideplayer, vortexbuicks, northern, faiauto, hemmings