5 Types of Gearbox and Their Components [Complete Guide]

What is Gearbox?

Types of Gearbox :- After the starting of a vehicle, the engine output shaft could not provide enough torque to control the weight of the vehicle. This makes it difficult to induce movement in the car at the initial stage. To overcome this difficulty a gearbox is used whose function is to supply initial high torque to move the vehicle.

At steep slopes, it is essential that the vehicle should be equipped with device that can provide a wide range of high torque; to fulfill this need a gearbox is required so that a vehicle can move upward on slope. ( Types of Reduction Gear )

Main Components of Gearbox

1. Main Shaft: ( Components of Gearbox )

Main shaft is the output shaft in a gearbox. This shaft is kept parallel to the lay shaft and in front of the clutch shaft or engine output shaft. The gears are changed using this shaft because it is connected to the gear lever

2. Clutch Shaft: ( Components of Gearbox )

This shaft is used to carry the output from the engine to the gearbox. It helps to engage and disengage the engine output.

3. Lay Shaft: ( Components of Gearbox )

The lay shaft is used to transfer the output of the engine to the main shaft by the continuous meshing of a gear on the lay shaft to the gear on the clutch shaft.

4. Gears: ( Components of Gearbox )

Gears are basically connecting circles with teeth on them. They rotate and meshes with another gear on the different shaft so as to transmit the circular motion between 2 different shafts. There are different types of gear such as –spur gear, helical gear, bevel gear and worm gear.

5. Synchromesh Shaft: ( Components of Gearbox )

They are the special devices used in modern gearbox (synchromesh gearbox) .They make the shifting of gears smooth by maintaining same speed of main shaft, lay shaft and clutch-shaft. They don’t have to slide over the shaft for the shifting of the gear.

6. Gear lever: ( Components of Gearbox )

This lever is operated by the driver to change or shift the gear. The movement of the lever is designed in a specific manner.

Types of Gearbox

A. Manual Transmission Gearbox

A manual transmission is the type of gearbox used in most of the vehicle on the road due to its low cost. It is the type of gearbox in which there are limited gear or speed ratios i.e., maximum of 6-speed and 1-reverse is there and the shifting of gears is a manual task performs by the driver by pushing or pulling the gear lever in predefined fashion. Use of clutch is necessary in Manual transmission gearbox.

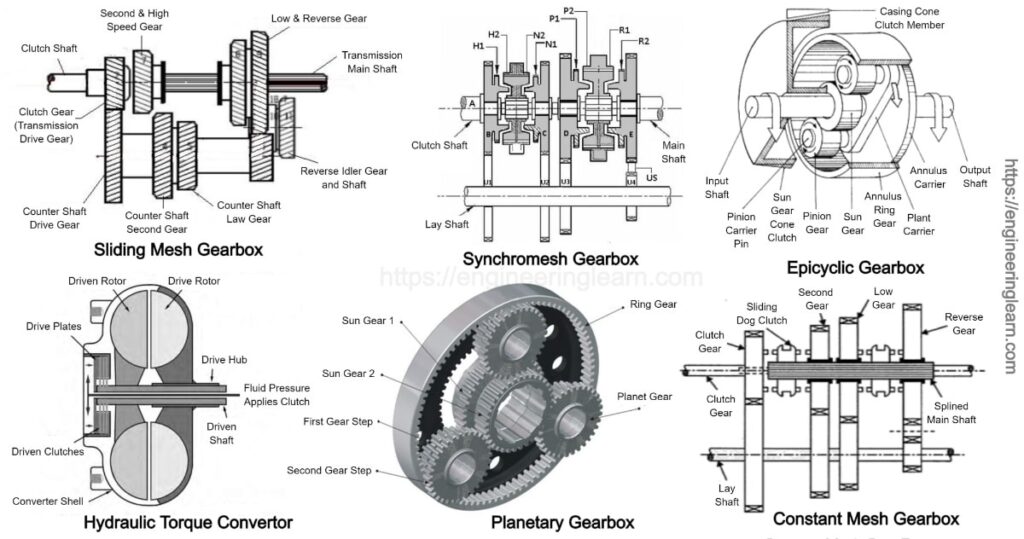

1. Sliding Mesh Gearbox: ( Types of Gearbox )

The sliding mesh gearboxes were mostly used in the olden days. In this type of gearbox the gears of main shaft and lay shaft are not in mesh. They are independent. In it, only a single gear is in continuous mesh with the gear on the clutch shaft. It rotates the lay shaft .The meshing of gears with the appropriate gear on the lay shaft occurs due to the left or right sliding of the gears of the main shaft.

First gear :- The gearbox provides maximum torque at a low speed. The smallest gear on the lay shaft is engaged with the biggest gear in main shaft. This helps in transmitting high torque.

Second gear :- In the second gear the gearbox provides low torque and high speed when compared to first gear.

Third gear :- The third gear, in the gearbox is responsible for providing low torque and high speed in comparison to the 2nd gear.

Fourth gear :- The dog shaft engages the clutch shaft and the main shaft in the fourth gear. This results in maximum rotation speed of the clutch shaft.

2. Constant Mesh Gearbox: ( Types of Gearbox )

The constant mesh gearbox is the modified version of the sliding mesh gearbox. This gearbox was created to overcome the limitations of the constant mesh gearbox. In this types of gearbox all the gears of the lay-shaft, main shaft and clutch shat are in constant mesh with each other. The shifting of gears in this type of gearbox is obtained by the sliding of dog clutches over the splined main shaft. This results in high speed or torque output.

3. Synchromesh Gearbox: ( Types of Gearbox )

In this type of gearbox, special devices known as synchromesh devices are used to provide smooth and quiet shifting of gears. These are among the latest of all the available manual gearboxes. The synchromesh devices helps in bringing the speed of all the shafts to the identical value (using frictional contact) before the meshing of the appropriate gears which causes less wear and tear to the gear.

B. Automatic Transmission Gearbox

The automatic gearbox is superior in many ways. They are generally used in modern day cars. They are expensive. The infinite gear ratios can be obtained by pressing the accelerator only. The driver can select the mode of the drive which can be- forward or reverse, park, neutral drive and sport. The selected gear sets the gear ratios along with the timing of the meshing automatically. Automatic gearbox comes only with 2 pedals as it doesn’t require clutch pedal.

1. Epicyclic Gearbox: ( Types of Gearbox )

The epicyclic gearbox uses the sun and planetary gears along with an annular ring and a carrier. The clutch shaft is connected to the sun gears which are in constant mesh with the number of planetary gear which freely rotates on their axis.

2. Hydraulic Torque Convertor: ( Types of Gearbox )

The hydraulic torque convertor gearbox consists of an impeller, a turbine, a highly compressed fluid and a stator. The stator is used for obtaining the different speed or gear ratios. This is controlled by the accelerator pedal. This impeller of the torque convertor is connected to the engine shaft the turbine is connected to the output shaft and the stator is placed in between these two to direct the flow of the fluid.

Image Source :- Sciencedirect, Theengineerspost, Elprocus