What is Beam? 25 Types of Beams in Construction [Explained with Complete Details]

![What is Beam? 25 Types of Beams in Construction [Explained with Complete Details]](https://engineeringlearn.com/wp-content/uploads/2023/01/Beams-1024x539.jpg)

What is a Beam?

What is Beam? 25 Types of Beams in Construction [Explained with Complete Details]: – The beam is a primary part used to resist the applied load. By and large, Beam is utilized to resist the shear force, vertical load, and bending moment. A Beam is a horizontal component that is imposed on endpoints between walls, columns, points of support, foundations, and so on. In the past beams were square, timber, metals, or stone combination of wood and metal for instance filth beams. Beams are utilized to convey vertical load.

A Beam is a flexible part that can resist compression and tension force. For instance, in reinforcement, steel has ability to resist tension. While concrete is used to resist the compression force. There is different types of beams, in light of shape, in view of geometry, in light of supports, and in view of equilibrium condition. Beam structures are a significant type of structural component that construction experts and a few types of engineers must be familiar with. These structural designs play a prominent role in how weight is transferred and guarantee that a building’s foundation is immovably planted in the ground.

What is Beam Structure?

A beam structure, at times essentially referred to as a beam, is a type of structure utilized in construction and development as well as engineering to provide a safe and productive load path that effectively distributes the weight all through the foundation of a building. These beams support the heap or load by resisting being bent under the load’s pressure. Beams resist this force in a horizontal manner as the force is applied to the axis.

By and large, the load distribution pattern incorporates a slab, beam, column, and foundation. This implies that the beam is embedded underneath the foundation and column to provide more comprehensive support all through the structure.

Why it’s Important to Understand Beam Structure?

Understanding beam structure is fundamental in construction and development as well as structural engineering in light of the fact that these beams are a primary way by which the building bears its weight. Beams ensure that there is a steady load path at the foundation of the structure so that the heaviness of the building’s rooftops, ceilings, and floors are appropriately supported. In construction and development, engineer experts should comprehend the type of beam that is generally suitable for a structure and how to effectively install beams to ensure the structure is built can withstand its own force.

Different Types of Beams

There are various types of the beam in view of their shapes, support, construction and development, etc. beams are utilized in the construction and development of structural designs. These are horizontal underlying components that support vertical loads, shear forces, and bending moments. The types of the beam as per different factors is given underneath:

A) Based on Construction Material

1. Timber Beam: ( Types of Beams )

The timber beam is by and large utilized in the wooden rooftop construction and development. They are utilized in combination with columns and posts which support beams in the wooden frame structure. The timber beam runs horizontally between two posts on the two sides of the wooden truss.

They are additionally used to support floor slabs in old houses made of timber materials. Timber is area of strength for durable building material on the off chance that proper treatment and care are taken.

2. Reinforced Concrete Beam: ( Types of Beams )

Reinforced concrete beams are the significant structural element of a building that are designed to convey transverse external loads.

This loadable causes bending moment, shear forces, and at times torsion across their length. As we realize that concrete is strong in compression and extremely feeble in tension. Thusly, to counteract and balance these deformities Steel reinforcement is utilized to take up tensile stresses in reinforced concrete beams.

3. Steel Beam: ( Types of Beams )

Steel Beams are manufactured from molten steel poured into molds and carried out in different shapes like Beams. Steel beams are durable and strong, high-strength material compared to other construction materials.

Steel beams are utilized in various types of construction and development like building, workshops, steel rooftop trusses, bridges, ropeway, and so on.

4. Composite Beam: ( Types of Beams )

A structural component that is made by utilizing two unique materials combined together to go about as a unit. An example in building construction and development, there is steel and concrete composite beam utilized.

B) Based on Loads & Supports

1. Fixed Beam: ( Types of Beams )

These are the sorts of beams where both ends are fixed and the rotational movement is restrained or limited. Also, the type of Beam which has no freedom to rotate at ends is a Fixed Beam. The End Connections of beams are provided with reinforcements to restrict the end rotation or tilting.

2. Simply Supported Beam: ( Types of Beams )

A simply supported beam is one of the significant and simple types of beam. It is the sort of beam where one end is the roller and the opposite end is pinned. The simply supported beam is the least complex structure element in light of the fact that both ends rest on support. In this sort of beam, one end is free to turn or rotate and does have not any ability to resist the moment.

3. Overhanging Beam: ( Types of Beams )

The overhanging beam is one like a simply supported beam, however, it’s one end overhand or extended from support to some distance. By and large, each end of the beam is supported by the segment. On account of an overhanging beam, one end of a beam is supported by a column and the opposite end is overhung without support.

Overhanging beams generally used to make shades or balconies, can differ from 40-120 cm in common residential buildings.

4. Double Overhanging Beam: ( Types of Beams )

As its name suggests it is a twofold overhanging portion on both the closures of the beam. In this kind of beam, the two ends of the beam are overhanging beyond the supports is known as double-over hanging beam. There is a difference between overhanging beam and double over hanging beam. In over hanging beam one side is overhanging while in the twofold overhanging both sides is overhanging beyond the supports.

5. Cantilever Beam: ( Types of Beams )

A cantilever beam can be characterized as a beam that is fixed at one and free at the opposite end. At the end of the day, Beam is fixed toward one side and the opposite end is extended beyond to hang free in the air. In these sorts of beams, the load coming on it transfers to the support where it can manage with the moment of force and shear stress.

The cantilever beam’s free end is the ability to move when the load is applied yet no rotation or interpretation will occur toward the end fixed end (end in the concrete). It is for the most part utilized in car parking areas, construction and development of bridges, towers, and so on.

6. Continuous Beam: ( Types of Beams )

A Beam that has more than at least two support is known as a continuous beam. It is like a simply supported beam. A beam is known as a continuous beam when it is simply supported at the two closures with intermediate support as well.

These kinds of beams have more than one span. A continuous beam is most commonly utilized in bridge construction and development. A beam of this kind has multiple supports along its length.

7. Trussed Beam: ( Types of Beams )

At the point, when the beam is reinforced with a truss, it is known as a trussed beam. Such beams are used by and large for making workshop sheds, and warehouse sheds, where there is a prerequisite for a long span and open space.

C) Based on Shape of Cross Section

1. Rectangular Beam: ( Types of Beams )

The rectangular beam is those which have a cross-segment rectangular shape. These sorts of beams by and large experience tension at the base and compression at the top. Therefore, greater reinforcement is provided at the bottom beam contrasted with the top portion of the beam.

Rectangular beams are the most well-known kinds of beams utilized in building construction from small house construction to high-rise building construction and development.

2. T–Beam: ( Types of Beams )

The beam has a cross-sectional shape like “T” which is known as a T-Beam. This beam is for the most part projected solidly with the slab. Thus, the slab goes acts as a part, an integral part of the beam, and bends in the longitudinal direction of the beam. The beam portion is known as a rib for T-the bar. The bar segment underneath the flange is known as the web. T-beam permits us to select a larger span contrasted with the rectangular span in light of the fact that the deflection of the beam is enormously diminished.

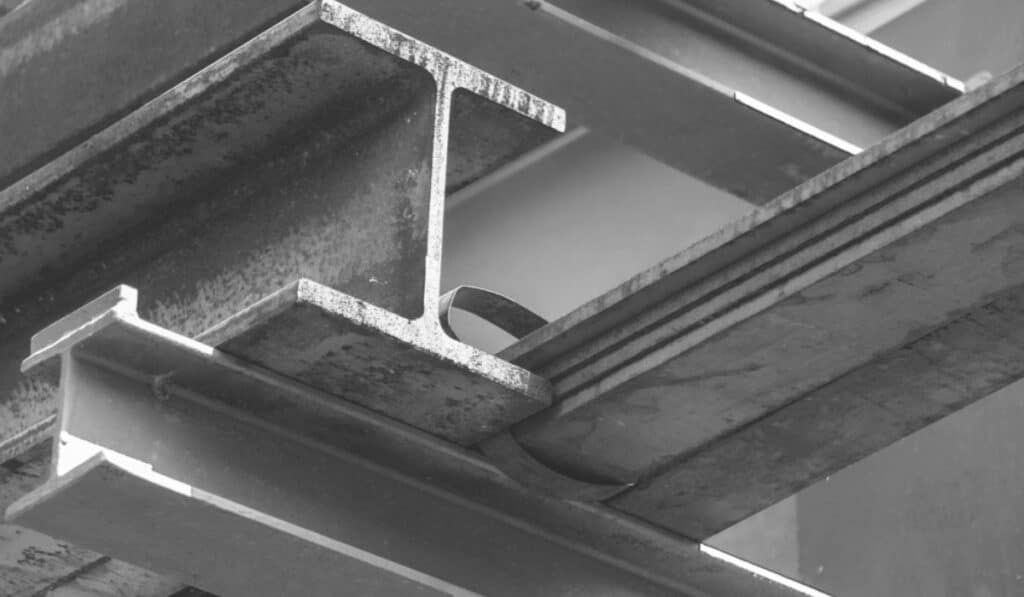

3. I –Beam: ( Types of Beams )

I – Beam is a basic method, the beam has shaped like the letters in order “I”. Likewise, it is a structural member looking like an “I”, meaning a central web with a crossbar at the top and bottom. I – Beam may be made of steel, cement, or fiberglass. I-Beam is for the most part utilized in the construction of manufacturing plants, multi-story buildings, and so on.

4. L –Beam: ( Types of Beams )

L – beam which is provided at the corner or around the border of the slab is called L-Beam. These sorts of beams are by and large found at the corners of building structures on which the rooftop/slab isn’t projected out of the beam, corners around the flight of stairs, lift openings, and so on.

5. C-Beam: ( Types of Beams )

The beam has a C cross segment. This sort of beam is otherwise called a channel beam or parallel flange channel (PFC). In c – beam there are two flanges and a solitary web.

This beam isn’t generally utilized in construction as regular beams on the grounds that the bending axis of c – beam isn’t centered on the breadth of the flanges. On the off chance that a load is applied on top, the beam will tend to twist away from the web.

D) Based on Geometry

1. Straight Beam: ( Types of Beams )

Straight beams are those which have a straight profile along the length. Most of the buildings are made with a straight beam.

2. Curved Beam: ( Types of Beams )

The beam that has a curved shape or profile is known as a curved beam. This sort of beam is utilized in curved places or a curved shape is required then this kind of beam ought to be used. There are two sorts of curved beams initially are the beams with small initial curvature, while the second is beams with a large initial curves, but there is no unmistakable conspicuous contrast in the definition of the first and second segments.

E) Based on Equilibrium Conditions

1. Statically Determinate Beam: ( Types of Beams )

If the forces applied on the beam can be resolved or found out by applying static equilibrium equations, then it is called a statically determinate beam. Likewise, we can say that in a statically determinate beam number or quantities of unknown forces are equivalent to the number of equations. Statically determinate structural designs are most commonly utilized in bridges, chiefly because of the way that temperature changes can induce large stresses in the bridge.

2. Statically Indeterminate Beam: ( Types of Beams )

On the off chance that the forces applied on the beam can be resolved or found out by applying static equilibrium equations, then it is known as a statically indeterminate beam. In kinds of a beam, the number of questions surpasses the number of equations, then the structure is statically vague. At the point when we provide more support to structure than expected for static stability, it makes structure indeterminate.

F) Based on Construction Methods

1. Cast In-situ Concrete Beam: ( Types of Beams )

The cast in situ concrete beam is constructed on the site. In this kind of beam, the new or fresh concrete is prepared on-site and poured in the shape or shuttering of beam for heavy construction the ready mix concrete is poured in shuttering of the beam after that it is permitted to solidify then the load would be imposed.

2. Lintel Beam: ( Types of Beams )

Lintel beams are for the most part provided on the top of the entryway, window, and ventilation frame. It has primary function is to confine the load that can act on the entryway and window frame. It conveys the load from the upper part to the sidewall on which it is upheld. The lintel beam is one of the fundamental components of the beam.

3. Precast Concrete Beam: ( Types of Beams )

The Precast beams are those which are projected or manufactured in a plant and away from the structure in an extremely controlled climate, and ideal conditions are provided for castings to ensure the maximum strength of the beam. The precast beam is manufactured or produced more suitable than on site construction and furthermore, the nature of the precast concrete beam is more noteworthy than that prepared on site.

The various sorts or shapes of the beam are manufactured in industrial facilities for example T – beam, H – beam, L-beam, C-beam, etc. They are cast at plants and relieved in an extremely controlled manner with a high-quality check. These precast beams are then transported to construction to utilize.

4. Pre-stressed Concrete Beam: ( Types of Beams )

As its name suggests they are pre-stressed prior to casting the beam. Concrete beam formwork is set up with tension wire in it and hydraulic jacks are utilized to give pretension before casting. Just prior to concreting in the beam, tension wire is stressed according to the requirement with help of a hydraulic jack. After that concrete is filled into it and cured. This casted beam is known as a prestressed concrete beam.

As we realize that concrete is strong in compression however weak in tension. There is a constant affords to decrease the tension force on the concrete members. Therefore, the concrete beam is prestressed with the goal that it will remain under compression more than in tension.

5. Post Tensioned Concrete Beam: ( Types of Beams )

The post-tensioned cement or concrete beam is manufactured on the site. Post-tensioning tendons are for the most part internal but it tends to be external. The benefit of post tensioned concrete beam is it doesn’t require a large number of ports which is required for per-tensioned concrete beam.

Conclusion

Understanding beams requires information on statics of engineering and designing and major material science. This understanding permits construction and development as well as engineering experts to identify the loads that will influence the beam and choose the right size, shape, and material for the needed beam effectively. Choosing some unacceptable kind of beam can bring about the structure not being adequately steady to endure its own load and could be detrimental with regards to the building’s life span and security.

Content Source: – civiconcepts, indeed

Image Source: – mainemtpostbeam, northern-weldarc, viriform, istockphoto, misfitsarchitecture, quora, steeltrussco, housing, c-beams, ansys, gharpedia, researchgate