Exhaust System Types and Components [Explained with Details]

What is Exhaust System?

Exhaust System Types and Components :- An exhaust manifold is responsible for collecting the exhaust gases from the cylinder head in the engine. After this, the exhaust gases are diverted from all the cylinders of the engine using the exhaust manifold which acts as a funnel which then releases them through a single opening referred to as the front pipe. As the final step, the gases will pass through a silencer or a muffler which makes a clean system in your car and ensures its smooth running.

Types of Exhaust System

- Single Exit Exhaust

- Dual Exit Exhaust

- Opposite Dual Exhaust

- Dual Side Exhaust

- High Performance Exhaust

1. Single Exit Exhaust

The single exit pipe is one of the most common type of exhaust systems which has the single exit type. One can find these fit on the cars and trucks which are bought from the dealer. These cannot be referred to as the most efficient pipes rather they are the cheapest to manufacture as well as install. The exit of the pipe shall always be on the passenger side of the car.

2. Dual Exit Exhaust

The dual rear exit exhaust system refers to as that system which is generally installed in the sportier cars or is added to make a vehicle seem sporty in look. It gives a really deeper note to the exhaust and thus makes the sound of the engine even more powerful. This system comprises of two exhaust pipes on the opposite sides of the car. It is important to know that pipes are not bent around the wheels unlike the other ones.

3. Opposite Dual Exhaust

These types of exhausts are used there where the dual rear exhaust systems cannot bend. Opposite dual exhaust systems are installed as they work a bit differently as compared to the other exhausts. These are wrapped around the wheel with the bend to add a filtering process. These type of exhausts will be seen more on vehicles which are used for towing large loads.

4. Dual Side Exhaust

A dual side exhaust system refers to as that system which has two pipes next to each other on one side. These two pipes are used to expel gasses more efficiently as compared to the single exit pipes. The look and sound of these exhausts is similar to that of a high-performance system which offers some enhancement in the performance.

5. High Performance Exhaust

High-performance exhaust systems are comparatively more expensive which is found doing a highly efficient job of filtering out the gasses. Whereas, these are not the standard and should not be fitted to the vehicle aftermarket but in some cases the high-performance exhaust system is found increasing the efficiency of a car and also the performance of the engine.

Designing an exhaust system

1. In Motorcycles

In most of the motorcycles the exhaust system is kept visible which is sometimes chrome plated as a display feature. The aftermarket exhausts can be made from material like steel, aluminum, titanium or carbon fiber. The exhausts of a motorcycle come in various varieties which depends upon the type of engine and its intended usage. A twin cylinder in a bike is found having an independent exhaust sections which is optionally a single exhaust section known as a two-into-one.

In the past, the motorcycles came as a standard with a single exhaust muffler which lasted till the early 2000s when the noise and pollution regulations were responsible for stopping this practice and forced the companies to use the other methods in order to increase the performance of the motorcycle.

2. In Trucks

In many of the trucks most of the exhaust system deliberately kept visible which often has a vertical exhaust pipe. Most of the trucks are found having the silencer which is surrounded by a perforated metal sheet which helps to avoid anyone being burnt by touching the hot silencer. This sheet can be chrome plated just for the purpose of display feature. Parts of pipe between the engine and the silencer is mostly a flexible metal which is likewise the industrial ducting that aims to reduce the vibrations coming from the engine to the exhaust system.

There are situations wherein the large diesel exhausts pipes are kept vertical in order to blow out the hot noxious gas away from people. In this type of case, the end of the exhaust pipe is particularly found having a hinged metal flap which stops the rainwater from falling inside it. The exhaust systems of the trucks in Britain are usually out of sight below the chassis.

3. For Two Stroke Engine

The two-stroke engines are mostly used in dirt bikes which has a bulge in the exhaust pipe known as an expansion chamber that uses the pressure of the exhaust to create a pump which squeezes high amount of air and fuel into the cylinder during the intake stroke. This mechanism is used to provide the greater power and fuel efficiency.

4. Marine Engines

The exhaust pipe is used to stop the engine from overheating the engine room where the people must work to service the engine. Adding water to the exhaust pipe cools the exhaust gas and thus decreases the back-pressure at the cylinders of the engine. In any marine service the exhaust manifold is integral with a heat exchanger that allows the sea water to cool in a closed system of fresh water that circulates within the engine.

5. Outboard Motors

In the outboard motors the exhaust system is considered as a vertical passage which passes through the engine structure with an aim to reduce the water noise that blows out underwater, sometimes through the middle of the propeller.

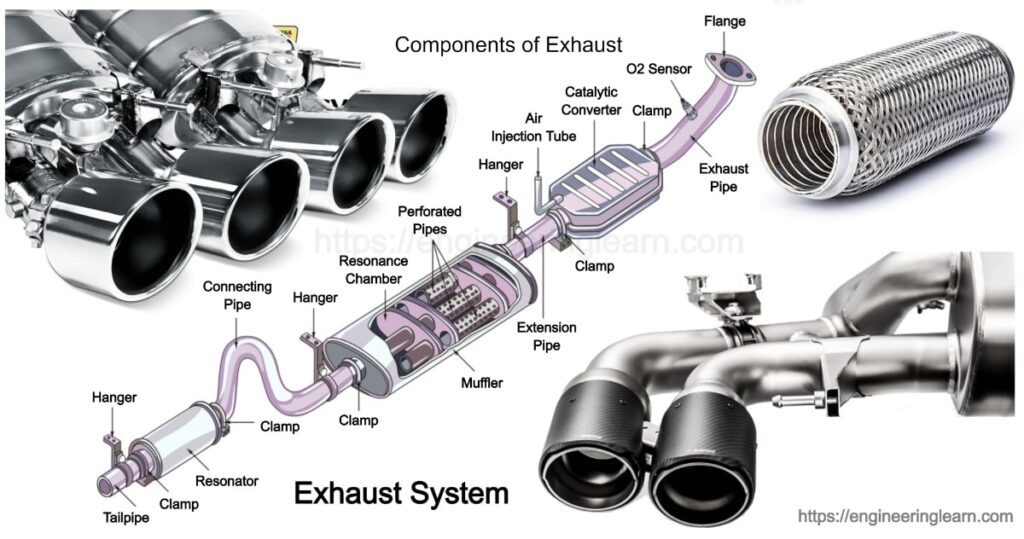

Components of Exhaust System

1. Tailpipe and Exhaust

In vehicles like trucks there are silencers is crossways under the front of the cab wherein its tailpipe blows out sideways to the offside. The side of a passenger car on which the exhaust exits under the rear bumper indicates that the market for which the vehicle was designed as most of the vehicles are found having exhausts on the right so they are furthest. The final length of the exhaust pipe is counted from its end from where the vent is opened to air.

Generally the only part of the exhaust system part on a vehicle which is visible is mostly ended with just a straight or angled cut which can include a fancy tip or can be chromed. This piece produces a final deduction in the pressure which is sometimes used to enhance the appearance of the car. The fashion was not appreciated once the customers noted that the rear end of the car, being at a low-pressure area, collected the exhaust and its acidic content ate into the chrome-plated exhaust.

(Exhaust System Types and Components)

Whenever any vehicle like bus, truck, tractor or excavator has a vertical exhaust pipe which is known as stacks or pipes and is sometimes placed at the end and has a hinged cover flap from which the gas flow blows out of the way for getting inside the exhaust pipe.

In some of the trucks the silencer is designed in a front-to-back manner, under the chassis and at the end of the tailpipe turns 90° and then finally blows downwards. This protects the stationary truck from getting a direct blast of the exhaust gas which can rise the dust when the truck is driving on a dry dusty surface.

2. Catalytic Converter

There are various systems which eliminate the catalytic converter. It slowly and gradually became the U.S. legal requirement where it became mandatory to have a catalytic converter. The converters might not be removed from the vehicle which are particularly used for off-roading. The main aim of a catalytic converter in an automobile industry is to decrease the harmful emissions of gases like hydrocarbons, carbon monoxide and nitrogen oxides into the atmosphere. These work effectively by converting the polluted exhaust components into water and carbon dioxide. There is a light-off temperature which is the effective starting point of the catalytic converters after which it works properly.

The catalytic converters can be found causing back pressure in case they are not designed for the required flow rate or in case if they are found to be clogged. In such conditions, upgrading or removing the catalytic converter can increase the power. Whereas, the catalytic converter is referred as a key component of the emission control systems of any vehicle. Thus a non-standard product can cause a vehicle to be un-road worthy. (Exhaust System Types and Components)

3. Exhaust Pipe

The piping refers to the one which is found connecting all the individual components of the exhaust system which is commonly called the exhaust pipe. If the diameter of the pipe is too small then the power at high RPM will be decreased whereas too large diameter can be responsible for reducing the torque at low RPM which might cause the exhaust to sit lower at the ground, and thus intending to increase the risk of it being hit and damaged while the car is in motion.

Talking about the cars which have two sets of exhaust pipes, a crossover pipe is commonly used to connect both the pipes. The common designs of crossover pipes include a perpendicular pipe commonly known as a H-pipe. This is named so due to its shape. The other one can be an angled pipes which can slowly merge and separate.

4. Muffler

The main role of a muffler is to decrease the effect of noise which is emitted from the engine. These are mainly installed inside the exhaust systems of any particular internal combustion engines. The series of passages and chambers is lined with a fiberglass insulation which resonates the chambers which helps the sound waves to cancel out.

5. Turbocharger

The turbocharger is that which comprises of pair of fans which aims to increase the amount of air that is entering the engine in order to add more power to the engine. This allows to deliver and operate the vehicle quite efficiently at any possible kind of altitude.

6. Lake Pipes

The name lake pipes is derived from its vast usage on the empty dry lake beds northeast of Los Angeles County, where the specialists of engine interchanged and evaluated one-piece header manifolds of varying thicknesses, temperature, humidity, elevation and climate in which they anticipated.

The lake pipes was evolved as a function of practicality. The manifolds routed a straight out from the front wheel wells giving a risk to the race driver. The lake pipes were fashioned in order to extend it from the header flange along the rocker panels, bottom-side of the vehicle, beneath the doors, thus allowing suspension tuners a lower ride and sufficient height for the ease of an engine tuners and flexibility of interchanging different exhaust manifolds without hoisting the vehicle, thus precluding having to wrench undercarriage of the vehicle.

(Exhaust System Types and Components)

The body on frame chassis designed to super leggera, unit-body and monocoque archetypes, in tandem with smog, as a bona fide performance. There was no meaningful gain in the performance to the latest vehicles. The lake pipes persisted into the 21st century as a superfluous, which was usually chrome plated with various options in order to allow the drivers to control whether the exhaust gas is routed with the standard exhaust system or through the lake pipes, which are fashioned commonly by the laker caps that is fixed by the fasteners at the end of the terminal of an exhaust tip, which serves as a cap, once the exhaust system is not in use or the signal authorities do not permit its presence.