V Engine: Introduction, Types, Working, Application, Advantages [with History]

Introduction of V Engine

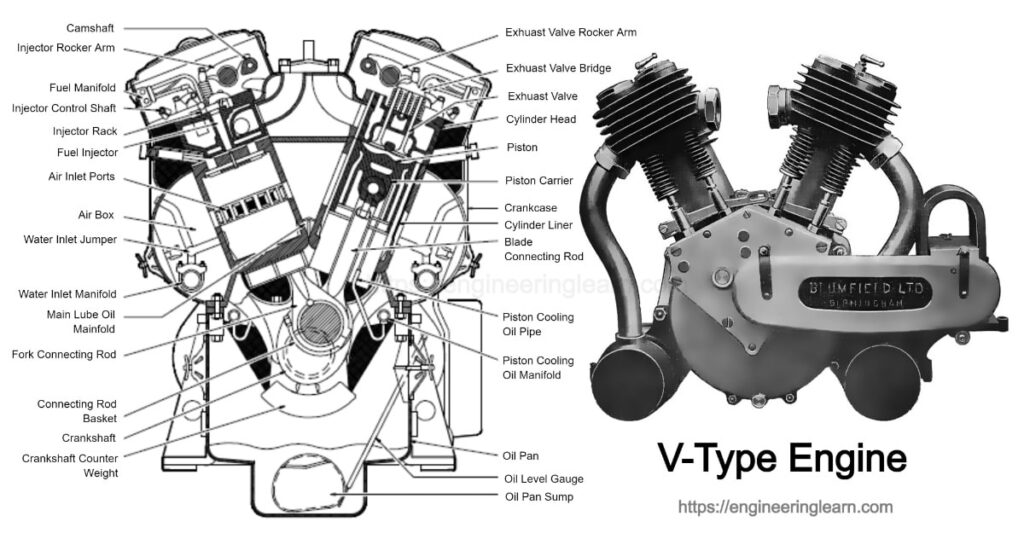

V Engine :- V types engine is also termed as a Vee engine which has a common configuration for internal combustion engines. The configuration of a V engine consists of two cylinder banks having the same number of cylinders in each and every bank which are inter connected to a common crankshaft. The cylinder banks are particularly arranged at an angle to each other in order to form a V shape from the banks whenever viewed from the front of an engine. ( Types of Engines )

The V engines are found having a shorter length as compared to any other engines and specifically compared to inline engines whereas the trade-off is of a larger width. The most common layout of an automobile engine is a V6, V8 or V12 engine which have six, eight or twelve cylinders respectively.

History of V Type Engine

The first V engine or a two-cylinder or V-twin, was designed by much known person Wilhelm Maybach which was used in the 1889 by Daimler Stahlradwagen automobile.

After the V engines were found, the first V8 engine was produced in the year 1903, which was designed by Léon Levavasseur and was used in racing boats and airplanes. The first V12 engines were produced by Putney Motor Works in London which was also used in racing boats. The first V6 engine which reached the production soon appeared after the year 1908, by a German based company to be used as a generator for electric railway engines.

Therefore, it was not until the year 1950 that the V6 engines were used in the series production of the automobiles. The first V6 engine was used at an angle of 60 degree to separate the crankpins for each cylinder in order to minimise the vibration issues which were experienced by the earlier attempts for producing V6 engines.

If it comes to a comparison then it must be said that the V engines are found with a quite shorter length but at the same time are found being quite wider. This is the effect which increases the number of cylinders in the engine, the difference of length between a V-twin and straight-twin engines might not be that significant whereas the V8 engines have a significantly smaller length as compared to the straight engines.

Specification of a V Type Engine

The V-angle or the included angle in between the banks of the cylinder varies significantly amongst the engines. There are various engines which have used a V-angle of almost 180 degrees which is same as that of a flat engine. These are the engines which are found in Ferrari V12 engines. On the other end of the scale, the V-4 engines and the VR6 engines use a small angle of 10 degrees only which includes a single cylinder head which is used by both banks of cylinders.

The engine balance of a V12 engine is same as that of a perfectly primary or secondary balance. The engine balance for V cylinders depends on the factors like the firing interval, crankshaft counterweights and presence of balancer shafts.

The V-type engine is found having two rows of cylinders which usually form an angle of 60° or 90° within the two banks. V-8 engines has eight cylinders usually having 90° angle, whereas there are various small six-cylinder aviation engines which usually have horizontally opposed cylinders. The particular placement of a camshaft is mostly overhead which is termed as overhead cam (OHC) or dual overhead cam (DOHC).

The compartment for the camshaft drive includes a gear, chain, or a belt within the front or rear end of the block or a cover plate. A belt which is toothed is usually used to ensure an accurate or responsive control of the valve train. The bell housing is formed near the rear cylinder block which encloses the flywheel and provides attachment for a transmitting housing. The water jackets are formed all over the cylinders with a suitably cored and connecting passage in order to circulate the flow of coolant.

V engine Working and Design

The design of the cylinder block gets affected if the location of the valves of the four-stroke-cycle engine is changed or deflected by the convenience of the ports of the cylinder in the two-stroke type. An overhead-valve engine was largely replaced by the L-head type as its valves are entirely present in the cylinder head. The block of cylinder of the engine is extended only to one side of the bores of the cylinder which has the valve seats and passages for the inlet and outlet together along with the valve guides which are formed in the extension of this block.

After this the cylinder head becomes a water-jacket cover which provides the threaded locations to the spark plugs with its underside profiled in such a way that the combustion chamber of a desired size and shape is formed above the bore of the cylinder. The shape of the space forming combustion chamber changes when the piston is at its closest approach to the head of the cylinder and its volume contained in relation to the piston which is displaced in reference to the volume which is extremely important and effects its performance.

The V engine is a next generation compact engine design which places the cylinders at a particular angle instead of a straight line with respect to each other. The angle amongst the cylinders varies mostly from 60 to 90 degrees. This angle forms a V shape between the cylinders, due to which the engine is known as V type engines.

Mostly the V-type engine is made with an even number of cylinders. For instance, the cylinders are in a multiple of 2 such as 4, 6, 8 or 12 and so on. This design considerably helps in reducing the height, length & weight of the engine as compared to any other engine design with an equal number of cylinders.

Applications of V Type Engine

The V engines on the other end are found having a complex design and therefore, carry quite high cost of manufacturing as compared to the other engines of the similar capacity. The 2-cylinder used is also known as the V-Twin. These are used by the manufacturers to typically employ them for high-end sports like bikes and cruisers. Whereas, on the other hand, high end super-bikes use V-4 design. V engine designs are most used in vehicles with engine capacity above 3.0 litre. The engine houses its camshaft in the head of the cylinder which is known as the Overhead Camshaft (SOHC or DOHC).

Most of the passenger cars like family sedans, SUVs and sports-cars are mostly found having V type engines only. Some of the cars with include V type engines are Toyota Camry, Mercedes Benz E 400 Cabriolet, C63 S AMG, E 63 AMG, G 63 AMG, GL 63 AMG, some of the BMW 5 series, 6 series & 7 series models and Ferrari 458 Special, Spider, 488 GTS, California T models.

Popular SUV cars with V type engine are: Toyota Land Cruiser, Land Rover Discovery-4, Range rover, and Audi Q5, Q7 etc. which are all high in demand in India.

Advantages of V Type Engine

- Smallest of all the eight-cylinder engines.

- The lower position of the bonnet helps in better aerodynamics.

- Increases the primary balance & reduces vibrations

- The smoother operation for high-speed performance

- Compactness makes it suitable for high-end sports-cars

Difference Between V ENGINE and INLINE ENGINE

Inline engines are also known as I engine due to the vertical placement of the cylinders, an inline engine arranges the pistons in such a way that they are kept straight facing the sky. The layout of an inline cylinder is most popular in all the rest four-cylinder engines, which are mostly prominent on compact sedans and crossovers. They engines can also accommodate odd numbers of cylinders.

A V-type engine has got its name from the slant or V-shaped placement of the cylinders, instead of standing vertically in a row. The pistons is kept leaning away from each other in order to form a valley-like separation. This layout on engines with six, eight, or ten cylinders is easily visible.

If you consider a particular V type engine, it has 12 cylinders set in a V with an angle of 60° and consists of a large part of technologies which are used on engines like TDI V6 and V8 Audi car. Including the petrol engines like 5.0 liters V10 TFSI and 6.0 liters W12, the V12 TDI is fit at the top of the range.

Designs of Various V Type Engine

This design was prepared in the year 2006 and was made available to all the huge companies of cars by the year 2010. The luxury car maker company like Audi has attempted to modify the angle of 90° to about 60° to achieve the best of an engine. A huge part of the technology is used on the V12 as a source of the V10, which is fit to the R10.The V12 is set with a B.S. injection system which has a common rail pressure of the injection which varies up to 2000 bar which is quite similar to the ones used in Audi R10. The V12 is found having characteristics like:

- Excellent Performance.

- Less power consumption

- Less Fuel consumption

- Less Noise and vibration

- Low earth

- V12 engine design, at an angle of 60°

- Electrically 5934 [cm3]

- Bore Stroke X [mm] 83×91.4

- Ratio of compression 16:1

- Air Circuit Turbocharging

- Maximum power 500 [CP] speed [rpm] 3750

- Maximum torque 1000 [Nm] speed [rpm] 1750-3250

The emission control standards tells that the crankshaft of the engine is wrought alloy steel which is highly resistance. In order to reduce the torsional vibration of the crankshaft, it has been provided with a shock absorber viscous. In order to increase the resistance to fatigue which has been opted for the solution with the crankpin journal tariff. So mainly there are two pistons, which oppose but still are connected via the con rod on the same trunnion crankpin. The design of the engine block was based on the experience gained with the V6 engines and V8 TDI. To get an increased rigidity, the engine block is poured cast lamellar graphite. Also the oil sump is made of aluminum in order to reduce the total mass of the engine.

Clamping and Injection System in a V Engine

The head of the cylinder contains the clamping system known as swirl. This system is designed in order to create the crescent of air in the cylinders in order to obtain the mixture of air and fuel more homogenous and complete. Also there is a filtration system which is set at the cylinder head gas of the housing. The injection system works with high pressure of injection which moves up to 2000 bar.

This mostly contains two ramps of fuel and two of injection pump, one for each row of 6 cylinders. This injection system is mostly divided into two circuits which are each controlled individually. The inlet pathway from where the air enters is also made up of two independent circuits. This is done as they contain an air filter, earth sensor of air and a cooling radiator of compressed air. Both the circuits are joined through the throttle before the blanking plugs.

There are systems like distribution system, oil pump and pumps of the high pressure injection which are driven with a chain. The crankshaft is responsible for causing an intermediate wheel. This causes the shaft of the exhaust camshaft. The shafts of the exhaust camshaft, by means of a gear train, located on the opposite side of the engine, causes the inlet camshafts. The head of the cylinder contains the camshafts, valves, the injectors, the glow plugs and a part of the pier of the inlet manifold. The camshafts are the tubular trouser which are responsible for giving them high rigidity.

More About V Type Engines

Every row uses a turbocharger in a 6-cylinder engine. The wind turbines are cooled with water and its geometry is adjusted with an electric actuator which minimizes the loss of heat and the exhaust manifolds are composed of two layers of the isolated metal amongst them with the air. In order to decrease the flow of turbulence of air at the inlet of the compressor, which is equipped with a trimmer of the flow. This is also done to reduce the noise which occurs due to flow of air once the compressor is fit with a shock absorber.

The gases are filtered and introduced again into the intake manifold. The oil vapours passes through the separator which possibly has the role of a filter and separates the liquid by oil to oil vapours. Depending on the temperature of the engine, the oil vapours which are introduced in the engine is due to an electrical resistor. The electronic control system of an engine uses a two injection computer which is connected to each other in a master slave. This concept is helpful in independent controlling of injection at each row of 6 cylinders.

The injectors are also provided with additional 8 holes of flow which improves the pulverization of the fuel in the combustion chamber. The injection is divided and is made according to the mode of operation of the engine. For a greater efficiency of the piston, it is provided with the radial channels which circulate the engine oil. The post-treatment system of the exhaust gas is again divided into two circuits. Therefore, the gallery for evacuating each row of 6 cylinder contains an oxidized catalytic converter and a particle filter.

All the relevant experiments were carried out between the years 1980-1986 which have shown too high values for vibrations and noises being produced by the V engine. It was tried to control using the types of rubber shock absorbers in order to reduce vibrations which were transmitted from the engine to the chassis. There were only three models which were found giving better results.