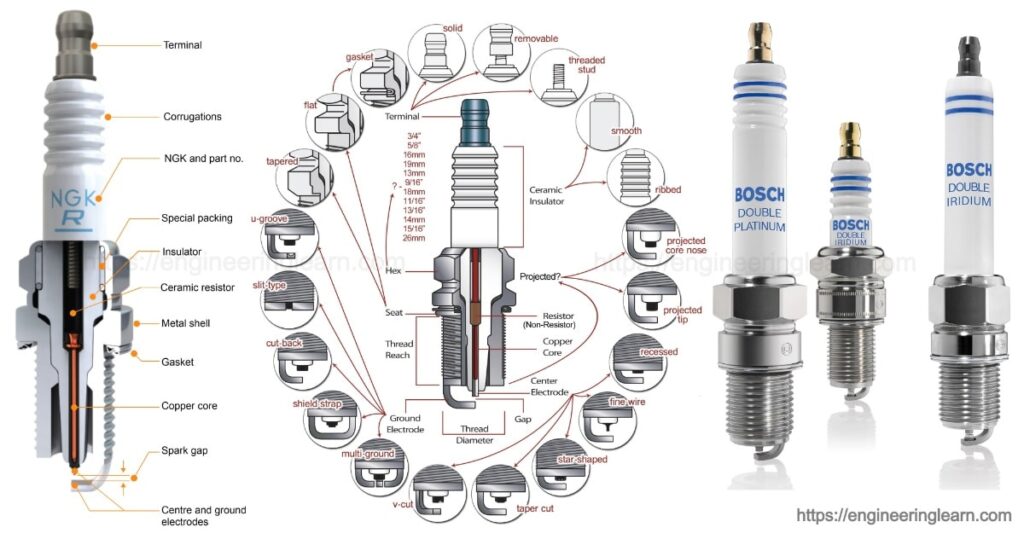

Spark Plug Parts [Explained with Details]

Spark Plug Parts :- A spark plug refers to as a simple mechanical device which is tasked with a couple of different devices but does a critical job. The main role of a spark plug is that it creates a kind of lightning between the combustion chamber or the cylinder head of an engine. The amount of electrical energy transmitted by a spark plugs is very high which is responsible for creating a spark within a controlled level of the combustion chamber.

Thermal Performance of A Spark Plugs

Whenever a spark plug initiates the spark in order to create combustion, the spark usually does not sustain it. However, it helps in transmitting the heat out from the combustion chamber into the water jacket of the cylinder head.

The spark plug is able to dissipate the heat from the combustion chamber and is defined by the spark plug as the heat range. The temperature of the firing end of the spark plug should mandatorily be at a very high level in order to prevent fouling whereas the low temperature prevents pre-ignition. This is also referred to as thermal performance by the manufacturers of the plug. The thermal performance or the heat range of the spark plug, are not interconnected in terms if the amount of energy which has been transferred from the ignition system via spark plug. The heat range is the area in which the spark plug only functions thermally.

Spark Plug Parts

When it comes to construct a spark plug then it may not be seem to be as simple as one might wonder. In fact, they are the most accurate pieces of equipment. Here are some of the most important parts which are used in the construction of a spark plug, knowing which is very important for a person who is indulged in these devices. Scroll down to learn more:

1. Ribs

The ribs are used to provide extra protection against the secondary voltage or spark flashover which is also found improving the grip of a rubber spark plug which is boot against the body of the plug. The shape in which the ribs are designed functions in order to improve the insulation of the electricity and also prevents the electrical energy from leaking along with the surface of the insulator from the terminal to the metal case. As long will be the path more electricity will be encountered with resistance along the surface of the plug even if there is presence of dirt and moisture.

2. Insulator

The body of the insulator is molded using ceramic aluminum oxide. For manufacturing ribs of a spark plugs, a very high-pressure and dry molding system is preferred. Once the insulator is molded, it is fired to an exceeding temperature which brings steel to its melting point. This process helps in determining the dielectric strength, thermal conductivity and resistance to shock. It is made using aluminum oxide ceramic and the outer surface of the plug is ribbed to provide grip for the boot of the plugs and to simultaneously add protection from crossfire.

3. Hex

The hex stands for the hexagon which provides the point of contact for a socket wrench. The size of the hex is usually kept uniform in the industry which is generally related to the thread size of the spark plugs.

4. Plating

The steel shell is mostly plated to enhance its durability and to also provide safety from rust and corrosion. Once the steel shell is fabricated to an exact tolerance with the help of an extrusion process, machined from the billets of the steel.

5. Gasket

There are two types of spark plugs, one are those which use gaskets while the others are the ones without gasket. The gasket is used in the plugs in order to provide a smooth surface and to fulfil the sealing purpose. Whereas, the spark plugs which are without gasket, use a tapered seat shell which completely seals the tolerance which is incorporated in the plug.

6. Threads

The threads of the spark plugs are usually not cut they are just simply cut. This is done to meet the necessities which are set forward by the International Standards Association (ISA).

Hot Spark Plug vs Cold

Cold spark plugs usually have a short path of the heat flow. In a result, this spark plug transfers the heat faster. In addition to this the short insulator available on the cold spark plugs has a small surface area which does not let the heat get absorbed massively.

Whereas, on the other hand, the hot spark plugs features a long insulator as well as a long path of heat transfer which results in a very slow rate of heat transfer to the cylinder head that surround it and the water jacket as well.

What is the Spark Plug Voltage?

When the spark plugs is attached with the high voltage which are generated by an ignition coil the electricity starts flowing from the coil. A voltage difference is made to develop amongst the center of the electrode and the ground electrode of the plug. As there is a gap present in the plug which is coupled with the air-fuel mixture, which is made to act as an insulator between the gap. This does not let the spark plugs fire immediately.

In case the voltage rises up to 20,000 volts, the gap between the spark plug can break and lead to firing it immediately. If the plug is removed from the head of the cylinder and grounded properly to fire then you might observe a definitive click. In case the condition is different than this then a spark can also be observed.

Inside the combustion chamber, high heat is created by the plug which helps in a small fireball between the gaps. The fireball or combustion expands due to which the cylinder experiences a complete combustion.

The voltage in a spark plug can range from nearly 20,000 to more than 1, 00,000 voltage.

Image Source :- pulstarpulseplugs, mechanical-engg, bosch