Alternator: Definition, Types, Working Principle, Parts, Uses, Components (Symptoms of Bad Alternator)

Definition of Alternator?

Alternator: Definition, Types, Working Principle, Parts, Uses, Components (Symptoms of Bad Alternator) :- An alternator is referred to as an electrical generator which is found converting the mechanical energy to the electrical energy in the form of an alternating current. In order to keep it cost effective and simplified, most of the alternators are found using a rotating magnetic field which is accompanied along with a stationary armature.

A linear alternator is the one which is also termed as a rotating armature along with a stationary magnetic field which is found to be used. For instance, if any AC electrical generator is found to be acting as an alternator, but the term refers to a small rotating machines driven by automotive and other internal combustion engines.

What is Working Principle of Alternator?

The working of an AC car is dependent upon the alternator which is found to be quite simple as well as less complex. It is found containing two different types of windings like a stator which includes a stationary outside winding and a rotor which is responsible for rotating the inner winding. The voltage regulator which is being supplied to the rotor winding is the result of energizing and turns it into a magnet. By using a pulley, the rotor is found to be rotated along with the engine through a drive belt.

As the magnetic field is found to be produced by the rotating rotor, it is found inducing the AC electric current in the stationary stator winding. The diodes which are found helping to convert the AC current into DC current the vehicle’s electrical system. Most commonly the voltage regulators are referred to as those which are found having built-in alternator. They are mostly found controlling the output of the voltage.

Automobile alternators are referred to as those which are relatively small as well as lightweight, which gets constructed with an aluminum outer housing. This light weighted metal is not responsible for magnetizing, this is the reason it dissipates the heat which is produced during the process and as the rotor assembly produces a magnetic field. You can also observe a vent on both the front as well as back of the alternator this is how it helps in the heat dissipation.

Conclusion of Working of Alternator

As the engine is found in a running condition, the crankshaft gets turned in the drive belt that is responsible for spinning the alternator pulley. As the alternator is found rotating, the current gets produced. This is the reason why it is said that the alternators are the ones which transfer the mechanical energy of the engine into an electrical power for the car components.

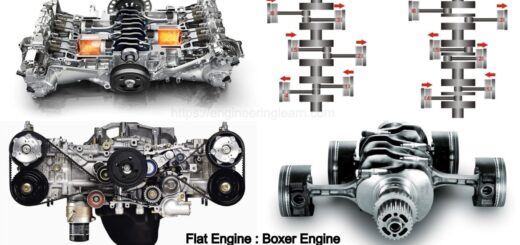

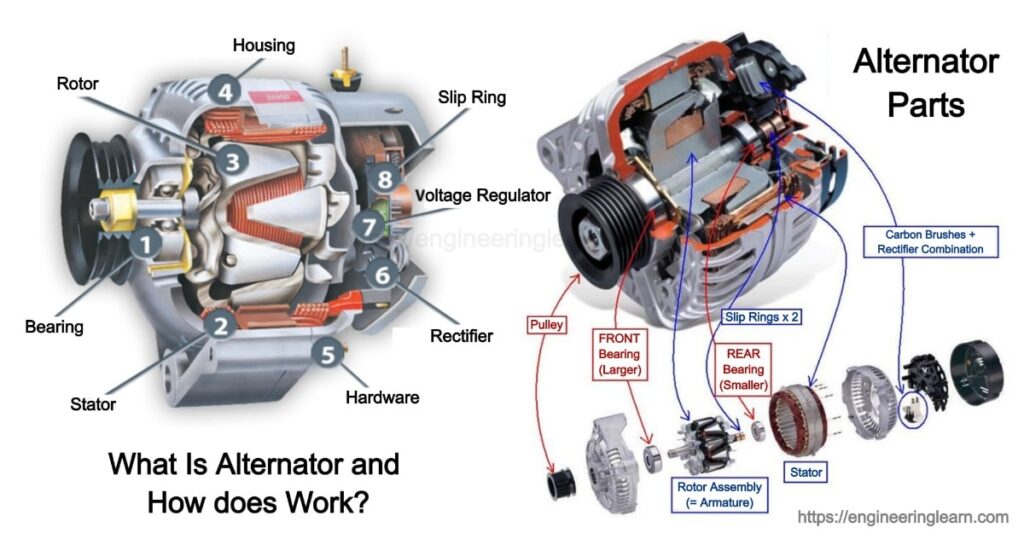

Parts of Alternator

Other than the types of alternator, you can generally find that there are three parts which are commonly known about the alternator: the stator, the rotor the diode and a voltage regulator.

1. Voltage Regulator

In order to control the charging process, the voltage regulator are found controlling the power supply from the alternator to the battery. Regulators are referred to as those which are found being designed for the purpose of work which depends on their specifications along with various different functions.

2. Rotor and Stator

A rotor and an alternator stator is referred to as that mechanical device which are known to be the group of magnets that are found being driven by the help of a belt which is responsible for creating a magnetic field inside the copper wiring.

A pulley is found connecting to the motor which is responsible for enabling the rotor in order to rotate at a consistently higher speed which is responsible for creating a magnetic field that is used as the belt. The stator is responsible for developing the electricity along with the voltage to flow into the diode mounting. The electricity which is thus created is referred to as the alternating current or AC.

3. Diode Assembly

DC is referred to as the current type which is mostly used by the car batteries and is converted into the direct current by the help of an alternator’s diode assembly (AC). The two-terminal diode assemblage is found working by allowing only unidirectional flow wherein the electricity is responsible for being generated by the stator.

4. Battery Recharge

The key feature of any alternator is found in the generation of the battery via electricity. Depending on the terrain and whether you use other electricity drain functions like the headlights or radio, it is noted that it can take about 20 to 30 minutes to get a new car battery with an un-functioned alternator. The alternator is referred to as that device which is also responsible for recharging the battery along with the usage of the car in order to make sure that the battery is comparatively good for a longer time period.

5. Alternator Functions

The alternator is a device which is known to be an essential part of any vehicle’s power system. The main function of the alternator is to convert the mechanical energy into an electrical energy, which it uses in order to charge the battery electrically. The alternator is also responsible for supplying the power to any other electrical components of the vehicle.

6. Powering Accessories

Most of the electrical systems are found consist of an alternator, whereas some of the power can be taken from the battery. One components amongst this is referred to as the electrical part of any car which is known as the alternator, and if it is suspected as not working properly, then you can use the least electricity in order to go where you can fix your alternator.

7. Mechanical Energy to Electrical Energy

The pistons which is present inside the crankshaft is the one where the combustion reaction takes place. It is noted that these are taken out of the gas tank. The crankshaft is the one which is found transmitting the explosive energy along with the combustion to an alternator-connected serpentine belt.

Whenever the pulley on the alternator is found to rotate, a magnet and a coil is the one which is found converting the mechanical energy into the electric energy and to also generate the electricity.

Different Types of Alternator

Depending on certain points like its usage, design, output power, cooling etc. the alternators are found to be categorized into various ways. Let’s scroll down to learn more about it in detail:

- Car alternators

- Diesel-electric alternators

- Marine alternators

- Brushless alternators

A) On the Basis of Its Output Power

- Single Phase Alternator which is responsible for generating one alternating voltage continuously.

- Two-Phase Alternator refers to as the winding which is found generating maximum flux in the first quarter, then the second winding is responsible for generating zero flux and the second winding which helps in generating the maximum flux and the first winding which is responsible for generating zero flux in the second quarter.

- Three Phase Alternator is referred to as that wherein the each winding voltage is found to be around 120 ° from one stage and the voltages in the other two windings. The windings are found to be linked along with a 3-phase output within the star.

B) On the Basis of Its Design

- Salient pole rotor

- Smooth cylindrical Rotor

What is Brushless Alternator?

A brushed alternator is the one which is found using a brush for the purpose of moving electricity through a generator or an alternator. The brushed alternators are responsible useful for the proper movement of the electric current, whereas, it is required to undergo a lot of maintenance. It is found that they have various movable parts that are found working together which can affect the rest of the alternators as well, even if anyone part is broken or malfunctioned.

On the other hand, a brushless alternator is found to be more suitable for longer as well as for more consistent usage due to no replacement or repair brushes and fewer internal parts are found to be damaged. There are two sets of rotors which are found to be rotating together in a brushless alternator in order to generate and transmit the electrical current. A smaller generator on the other end of the device is used by a brushless alternator in order to transfer any electrical current. This is the main and direct benefit over a brushed alternator as there is no replacement or repair brushes which can save your money and time in the long term.

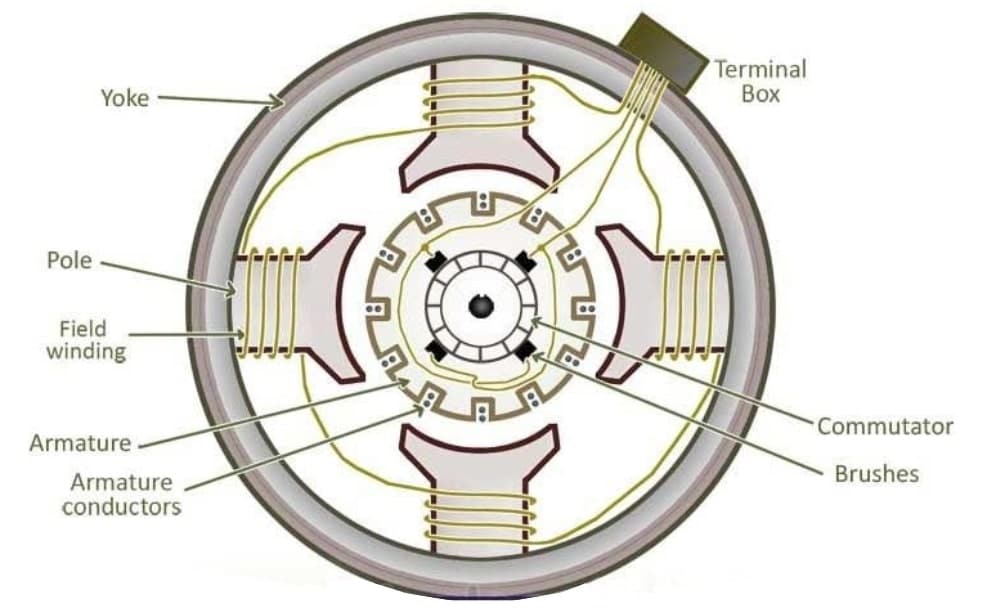

Difference Between Alternator And Generator

A generator is referred to as that mechanical instrument which is responsible for converting the mechanical power into either fuel or electricity. It is commonly found that there is a revolving rectangular coil which is responsible for the rotation around the axis in the magnetic field.

Two slip rings are found to be connected within the ends of the coil. The slip ring is responsible for absorbing the induced current of the coil which afterwards transfers it to the external load resistance R. The rotating coil is also known as the copper-made armature.

- An alternator is referred to as a machine which is responsible for converting the mechanical electricity from the primary mover into the AC, while the generator is the one which is found converting the mechanical energy into either AC or DC.

- An alternator is found having a rotating magnetic field yet a generator which is found having a rotating magnetic field for the generation of high voltage along with the stationary low voltage magnetic field.

- Input is observed being supplied by the alternator from the stator, whereas in the case of a generator, it is found to be supplied to the rotor.

- An alternator’s armature is found to be stationary whereas it is found rotating in a generator.

- The output voltage of a generator is found to be variable whereas the generator output voltage is found to be constant.

- The alternator does not charge the battery which is found to be completely dead, whereas the generator is found doing this.

- The output of the alternator is known to be more powerful as compared to the output of the generator.

Where are Alternators Used

Alternators are referred to as mechanical devices which are found producing the power for the electrical systems of all the modern vehicles. Previously, the DC generators or dynamos were responsible for this instead whereas after the development of the alternator, they got replaced with the DC dynamos since the alternators are found to be more robust as well as lightweight compared to others.

1. Uses in Car Automobile

Since the electrical system of the motor vehicles is found requiring a direct current and not the alternating current, whereas an alternator is found using it alongside a diode rectifier in order to convert the current from AC to DC. Irrespective of the need of conversion of current from AC to DC, an alternator is still found having its applications used as it lacks the complicated commutation which is present in a DC generator. This particular type of generator which is used in the vehicle is referred to as an automotive alternator.

Another use of an alternator is in the diesel-electric locomotive. The engine of this locomotive is nothing but is a type of an alternator which is mostly found to be driven by a diesel engine.

2. Uses in Marine Automobile

The alternating current is found being produced by this generator which is responsible for converting the current into DC by the use of integrated silicon diode rectifiers in order to feed all the DC traction motors. These DC traction motors helps in driving the wheel of the locomotive. The use of this machine can also be done in marine automobiles which is similar to a diesel-electric locomotive. There are designers who design the synchronous generator which are mainly used in marine as well as navy along with an appropriate adaptations to the salt-water environment.

The typical output level of a marine alternator is nearly found to be about 12 to 24 volt. Whereas, in the big marine sheep, it is found to be more than one unit which is used in order to provide massive power.

Talking about the marine system, it can be said that the energy is found being produced by the alternator which is initially rectified and is then used for the purpose of charging the engine starter battery along with the auxiliary supply battery of the marine. This is one of the most primary use of an alternator which is found being popular in the production of bulk ac power for commercial purposes. Considering the cases of thermal power plants or hydroelectric power plants or even in the nuclear power plants, alternators are the ones which are only used for the process of converting the mechanical energy into electrical energy for the purpose of supplying the power system.

Components of an Alternator

Here are some of the mentioned components of alternator which are found to be important for every human being to know about. There are also some of their additional functions to this which will make your clear about its need:

1. Rectifier

The rectifier is referred to as mechanical instrument which is mostly used in order to convert the alternating current (DC) which is produced to direct current (DC) during the process of charging.

2. Regulator

The voltage regulator is referred to as a part which is found controlling the amount of power supply which is found along with the alternator to the battery. The charging process is also controlled as it is specifically designed with numerous functions which depends on the type of work, depending on their applications too.

3. Stator

A stator is referred to as an iron ring which is found consisting of several coils of wire that are wound around it. The part of the stator is responsible for serving as the body of the alternator, which creates an electrical current when a magnetic field is made.

4. Rotor

The rotor is referred to as a part which is found spinning inside the alternator and is also responsible for rotating the pulley which drives the belt system along. It helps in acting as a spinning electromagnet.

5. Slip Rings

The slip rings are referred to as a means of obtaining direct current which are found offering power to the rotor.

6. Pulley

The pulley is referred to as a part which is found being connected to the rotor shaft and the drive belt system. Although the rotation which is obtained from the engine gets transferred by the drive belt to the pulley. The rotation thus causes the charging process.

Alternators are the ones which are found containing some functional tiny components in them. Inside any electrical device, you will simply be able to find a diode rectifier or a rectifier bridge, voltage regulator, slip rings and brushes. One can also find the rotor field winding, finger poles, field winding, stator etc.

7. Drive End Bearing

The drive end bearings is referred to as a mechanical device which helps in order to support the rotation of the rotor shaft.

Working of An Alternator

There are mostly three main elements which are known to mankind in a car charging system which are the battery, the tension controller and an alternator. In the case of a battery, the alternator is the one which is found providing electricity for all the electrical equipment of a car such as the inside and outside lighting system and the instrument panel.

Alternators are usually the ones which are found to be located near the motor front and are then driven by the help of a crankshaft which is responsible for allowing the upward as well as downward movement of the pistons into the circular motion.

There are various alternators which are found to be connected to a specific point on the engine using the brackets. One bracket is mostly found having a fixed point, whereas the other bracket is the one which can be modified in order to tighten the driving belt. Alternators are usually those mechanical devices which are responsible for generating an AC power by electromagnetism. This is the way by which the electricity is found to be transmitted into the battery and the different electrical systems work with a voltage.

Symptoms of Failing & Bad Alternator

Here is one of the most common thing that often occurs in most of the vehicles during the charging system wherein the battery icon is found to get a warming light due to the dashboard will be on while driving.

The warning light is found to be present on, whenever the ignition of the car is on, whereas it will get off as soon as the engine gets started. If the indicators are still on then this indicates that there is an issue which has not been resolved yet and this is mainly with your engine charging system.

In this type of situation you must try to refer to a professional which will be able to examine the engine, as the warning light will not be directly telling us about the problem. But it is common that the alternators are a common problem for such a sign.

In case you are having a weak charging system, then you will be able to see the dashboard lights along with the headlights which will get dim and will become brighter as soon as the engine is recharged. This is one of the major issue which can be caused due to a weak alternator, failing battery, poor battery connection or loose serpentine belt. You can also observe a sound from the alternator which is another symptom of failing the alternators. This can be caused due to a faulty bearing which can be present inside the alternator.

Most of the alternator problem include problems like worn contact rings, worn carbon brushes, or a failing voltage regulator. It is important to know that rebuilding the alternator is some most typical jobs.

Image Source :- iceeet, carthrottle,