What is Swaging? Types, Benefits, Process, Application & Advantages [Types of Swagers]

![What is Swaging? Types, Benefits, Process, Application & Advantages [Types of Swagers]](https://engineeringlearn.com/wp-content/uploads/2021/12/Swaging-1024x539.jpg)

What is Swaging?

What is Swaging? Types, Benefits, Process, Application, Advantages & Disadvantages [Types of Swagers] :- Basically, swaging is a type of metal forming process that is used to reduce the diameters of a cylindrical rod, wire, or tube. Unlike other metal forming methods, the process of swaging makes use of a rapid succession of hammer strikes to form the metal workpiece. This chip-less metal forming method is a really elegant and efficient way to manufacture products with very little waste of material. Swaging is a highly economic process to create point tubing, rod, and wire for redraw. Swaging can also be utilized to change the size, reduce, shape, taper, bond, or form metal parts.

Benefits of Swaging

Swaging offers a vast range of benefits to industries that choose this process of metal forming.

- Provides high finish – Since after swaging the end result includes a high surface and product finish, it can eliminate the requirement for any secondary process for finishing, hence saving both time and money.

- Speeds Assembly process – The fittings manufactured can be easily attached to a wide variety of other components which include wire cable, tubings, hoses, flexible tubings, and rods. Tubes can also be effortlessly crimped together.

- Less Material is utilized – Since the raw material is hammered, it is displaced longitudinally, unlike being chipped away and wasted.

- Saves on Labor – Since the presence of highly skilled operators is not essential, multiple machines incorporating several feeders and material handling systems can be operated just by a single operator.

- Reduces the need of having inventory – Since this process can be utilized to swage to the exact sizes, dimensions and finishes required, fewer components and tools have to be kept on-hand for operation and controls.

- Control of Wall Thickness – By utilizing a mandrel, the swaging process provides more control over wall thickness throughout the entire process.

Swaging Machine

A swaging machine is a mechanical device that is used to shape or change the dimensions and sizes of the workpiece by forcing it into a die or a series of multiple dies. This machine is further divided into two categories: tube or wire swaging or rotary swaging.

Tube swaggers are those machines that in order to change or reduce the diameter pull the item through a die r while a rotary swagger is a machine that features a series of multiple dies utilized to hammer form the workpiece. The swagged parts are typically cold worked throughout the process, although some amount of heat may be utlilized in some applications. Swaging machines can also be employed to impart internal profiles inside hollow parts.

Types of Swaging

The swaging process can be further classified as internal, external, combination or dual varieties.

- Internal swaging deals with granting a hold to the hose matter. It is generally used to enhance the flow area through tubing or hoses. As a matter of fact, this form of the swaging process can be used to increase the size of applicable items and work-pieces and plays an important role in reducing the risks of accumulation of bacteria near and around the end of any hose or tube. Internal swaging is also helpful in reducing the turbulence by providing a firm mechanical adhesiveness and bond.

- External swaging, as the name suggests, is exactly the opposite of internal swaging.

- Combination swaging is somewhat similar to external swaging, except that combination swaging, unlike external swaging welds the ends together. This process is also known to be better in terms of cost-effectiveness than external swaging. The process of combination swaging involves compressing the size of items to suit the purpose of requirements.

- The dual swaging is a type of operation that makes use of both internal as well as external swaging and it involves compressing both aspects of the workpiece by the same amount nt.

Types of Swagers

1. Stationary Swagers

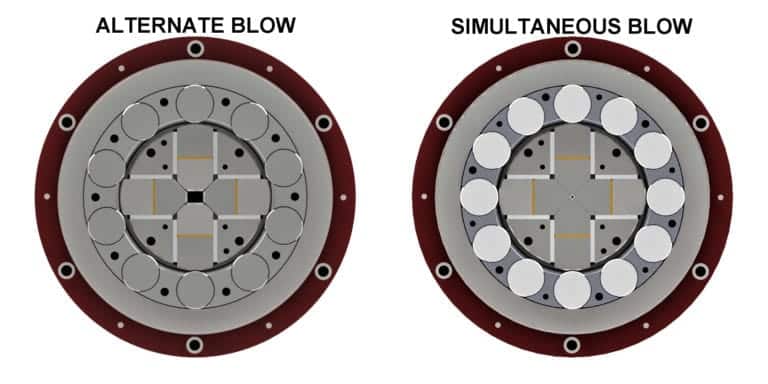

A stationary swager can be easily utilized to manufacture entire parts ranging from entry rounds, squares, or rectangles. Stationary swagers can manufacture any type of cross-section other than a perfect circle and can effortlessly perform both hot as well as cold swaging operations. During the stationary die swaging operation, the spindle assembly of the machine remains stationary and the roller cage rotates.

Generally, there are two types of stationary swagers, namely simultaneous blow and alternate blow. On a simultaneous blow stationary swager, a stationary swager can produce fluted shapes and cross-circular sections. Whereas the alternate blow stationary swager machine is capable of forming rectangular shapes, squares, and hexagonal shapes can be produced. Some examples of applications of stationary swager includes manufacturing of aerospace tube components and fluid control tubes.

2. Rotary Swagers

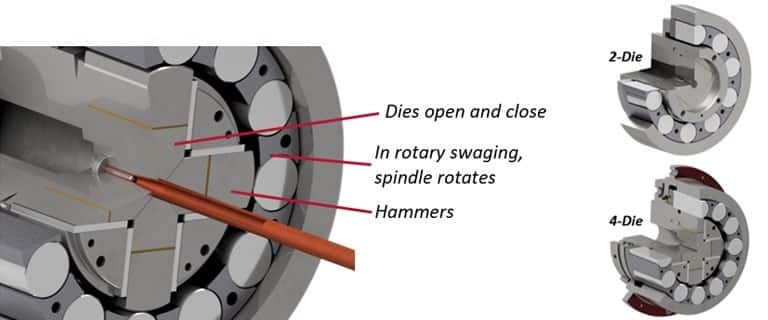

The rotary swaging machines are typically utilized for pointing, sizing, and forming metal wires, rods and tubes. In a rotary swaging machine, forming dies backed by hammer blocks revolve around the workpiece. When the spindle revolves within a rotary swaging machine revolves, a centrifugal force is produced which tossses the hammers in the outer direction and dies outwards against a sequence of numerous rollers adjoining the spindle.

Each time a hammer block strikes a diametrically opposite roller, they are driven further inward, hence causing the die halves to close and compress the metal workpiece being swaged. Rotary swagers generally have either a 2-die configuration or 4-die configuration. The swaged section of rotary swager machine is always circular. Examples of utilization of rotary swaging machine includes the manufacturing of cartridge heaters, hypodermic tubing, producing piping, armaments, and logging industry applications.

The necessary die configuration for manufacturing in rotary swagers is specific to its application. A 2-die rotary swaging machine is commonly used for the manufacturing of small parts and components and produces a better surface finish. The rotary swaging machine equipped with a 4-die configuration is applied for making pointing. This machine can make higher initial reductions on bigger parts.

3. Hydroformers

Hydro formers are in general employed for assembling certain parts, such as cables fittings, and for producing reductions between shoulders such as produced on a convoluted tubing. Hydroforming is a process which was made by making some modifications in the rotary swaging principle where wedges are employed to open the dies while the spindle rotates such that the workpiece can be inserted before and removed after the swaging process. Some general applications of hydroforming swaging operation includes ailing rigging equipment, manufacturing of architectural cable railings, and producing recreational ropes course cables.

4. Long Die Swagers

The Long die swaging machines incorporate the use of the same working principle as the rotary swaging process to manufacture long, shallow tapers for products such as furniture legs, multiple sporting goods, and some products utilized in the aerospace industry. It can be utilized for tapering tubing up to 24” in length. Long die swagers are capable of manufacturing over a wide variety of materials, including both welded as well as seamless tubing of either ferrous metals or nonferrous metals, ranging from stainless steel to aluminum. A long die swager is required only when the taper length exceeds the standard die length limits on a rotary swager.

Swaging Process

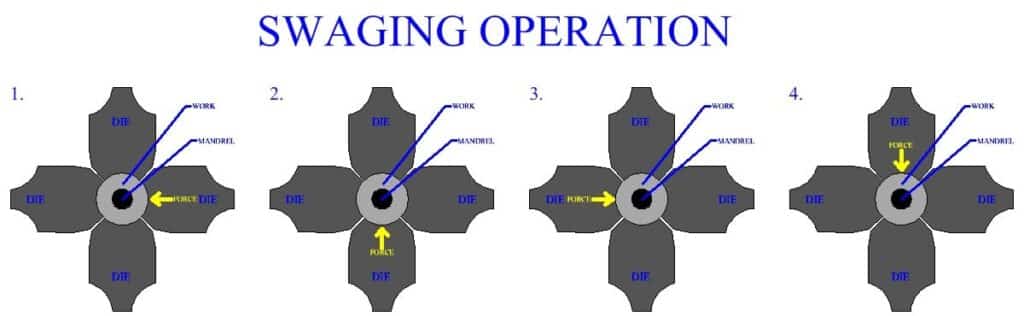

In the swaging process, the diameter of the workpiece rod or a tube is gradually reduced by forcing it through a confining die of specific dimensions. A set of reciprocation of this process through multiple dies provides radial blows to the workpiece, causing the metal to flow inward and slowly acquire the form of the die cavity at the end. The die movements can either be of in–and–out type motion or rotary type motion. The latter type of motion is typically obtained with the assistance of a set of rollers enclosed in a cage, in a configuration similar to that in a roller bearing. The workpiece clutched motionless as the dies rotate. This in turn causes the dies to hit the workpiece at a pace approximately as 10 – 20 strokes per second.

In tube swaging operation, the tube thickness and/or internal diameter of the workpiece tube can be controlled and modified by utilization of internal mandrels. For tubing of small diameters, a thin rod can be employed to function as a mandrel. Even internally shaped tubes can be effortlessly swaged by utilizing shaped mandrels.

The entire swaging process is quite versatile. The maximum diameter of workpiece which can be swaged using this operation is limited to somewhere about 150 mm and workpieces that are as small as 0.5 mm in diameter have also been swaged. The production rate through swaging can go as high as about 30 parts per minute, entirely depending upon the complexity of the part shape being manufactured and the means adopted for handling those parts.

The parts which are manufactued by swaging operation have carry tolerance in the range of somewhere around ± 0.05 mm to ± 0.5 mm and bundled with improved mechanical properties of the material. Employing the use of lubricants throughout the process helps in obtaining better work surface finish and promsies longer die life. Workpieces made from materials such as tungsten and molybdenum are swaged usually at elevated temperatures since they have low ductility at room temperature. Hot swaging is also sometimes employed in order to form long or steep tapers, and for making large reductions..

Applications

- Utilized in closing of tubes, producing tapering, clamping and steps in sections

- Manufacturing of many different section types is possible either parallel or tapered

- Tool shafts

- Punches

- Chisels

- Handles

- Exhaust pipes

- Cable assemblies

- Architectural work

Advantages

- This process can be utilized for mass production.

- The process is quite easy and it does not require the presence of any skilled operator.

- Low manufacturing cost.

- High surface finish.

- No wastage of material occurs as unlike other forming processes it does not form any chips.

- This process can be incorporated to manufacture products with high accuracy.

- Any material can be formed with the help of swaging process.

Disadvantages

- It is noisy operation.

- This process is restriced based on the diameter of rod and die.

Image Source :- thelibraryofmanufacturing, fenn-torin