22 Types of Tunnels – Uses, Advantages & Disadvantages [Explained with Details]

![22 Types of Tunnels - Uses, Advantages & Disadvantages [Explained with Details]](https://engineeringlearn.com/wp-content/uploads/2022/12/Tunnels-1024x539.jpg)

Introduction

22 Types of Tunnels – Uses, Advantages & Disadvantages [Explained with Details]: – A tunnel is a horizontal way located underground. While erosion and different forces of nature can form tunnels. There are various ways of uncovering a passage, including physical work, explosives, fast warming and cooling, burrowing hardware, or a blend of these methods. Tunnels are counterfeit submerged burrows that are worked without harming the outer layer of the earth. The passages are submerged paths utilized for the most part for transport purposes. They might be utilized to move cargo and voyagers, water, and disinfection, individually. Burrows forestall disturbance or association with surface life including traffic all through development.

What Are Tunnels Used for?

- Tunnels are utilized for the mining ores.

- They are additionally utilized for transport like road buses, trains, trams as well as canals.

- Tunnels are utilized for driving water and disinfection.

- Underground chambers, for the most part, connected with a network of interconnected tunnels as well as shafts, being much of the time utilized in those things as underground hydroelectric power plants, mineral processing plants, pumping stations, car parks, oil and water storage, water storage, water treatment plants, warehouses.

- Tunnels are likewise utilized for Light turn of events.

- Tunnels are now and again utilized for Special necessities of the military.

How Are Tunnels Built?

Tunnels were created in sorts of materials ranging from soft or delicate mud to heavy stone. The process of tunnel design or configuration depends on perspectives including, landscape conditions, groundwater circumstances, the diameter including the length of the tunnel drive, its size of the tunnel, its material support for tunnel drilling, the final application including a form of the tunnel along with the necessary risk management.

How Are Underwater Tunnels Made?

An underwater tunnel is a tunnel that is partially or entirely built underneath the sea or maybe an estuary. These are likewise utilized when constructing a bridge or running a ship interface isn’t feasible, as well as provide support or relaxation for existing bridges or ship associations.

Although short tunnels are generally road tunnels that can be utilized for mechanized, unmotorized, or even both, ventilation issues contribute to the lengthy tunnels.

Types of Tunnels

There are three types of tunneling that are commonly utilized. These are Cut and cover tunnels, bored tunnels, and immersed tube channels. The decision of what type of tunnel ought to be constructed is decided during the planning process considering the kind of soil and materials engaged in the activity.

1. Cut and Cover Tunnel: ( Types of Tunnels )

This tunneling method or technique includes utilizing excavation equipment to dig a large rectangular hole in the ground which is subsequently covered by a concrete deck. When the deck is placed, surface activities can be resumed though construction work continues underneath. It is basically utilized when the tunnel profile is shallow and the surface excavation is conceivable within an economical budget. As urban areas have limited space the tunnel is built or constructed within a near excavation line with the assistance of braced or tied back supporting walls.

2. Immersed Tube Tunnel: ( Types of Tunnels )

This tunneling process is principally utilized for underwater crossings. This undersea tunnel is composed of segments, constructed in a different areas and floated to the tunnel site to be sunk into where they are then linked together. This method is generally utilized related to different kinds of tunnels toward the end, for example, bored and cut and cover tunnels. There are three unique sorts of tunnel components built under this technique.

3. Bored Tunnel: ( Types of Tunnels )

This tunneling method or strategy involves digging a tube-like passage through the earth. It can be constructed both on the mountains and submerged bodies. This method is accomplished by utilizing Tunnel Boring Machines as explosives can trigger natural hazards on sensitive land. At present, it is the most expensive kind of tunnel making yet it additionally reduces the possibilities of rockfall.

4. Concrete Tunnels: ( Types of Tunnels )

These tube channels are utilized for double and different tubes where rectangular shapes are required for interior clearance of traffic and conformity to weight and resistance.

5. Steel Shell Tunnel: ( Types of Tunnels )

This structure comprises of thin-walled composite steel and concrete rings and provides a water barrier. The ballast concrete is set outside the shell between the structural diaphragms. The shell can be prefabricated and furthermore gives a water-tight environment. It tends to be segmented into more modest pieces where there is a limitation on casting and floating.

6. Steel-Concrete-Steel Sandwich Tunnel: ( Types of Tunnels )

Both interior and external surfaces are constructed with the help of structural steel plates. Shear connectors along with steel diaphragm plates are used between both the surfaces and loaded up with non-shrinking and self-compacting concrete.

A) Classification of Tunnel Based Upon the Usage

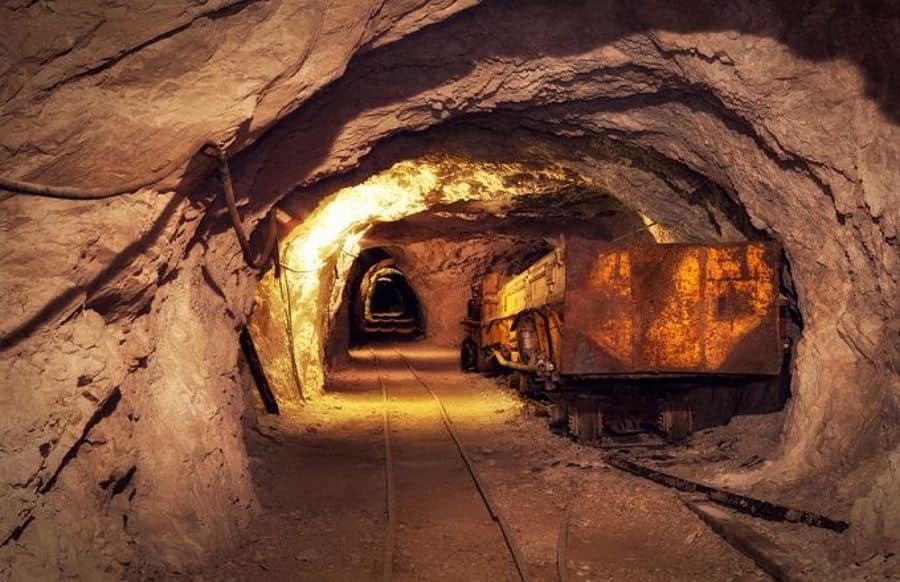

1. Mine Tunnel: ( Types of Tunnels )

It is utilized for ores, minerals, and metal extraction from the crust. They are less expensive to build in contrast to other channels. It isn’t safe since it is intended for long-lasting occupation.

2. Transportation Tunnel: ( Types of Tunnels )

It carries railways, pedestrians, the subway, etc.

3. Public Water Tunnel: ( Types of Tunnels )

It conveys or carries sewage, gas, or water for public utilization. Prior these tunnels were utilized for transporting water into densely populated regions. These were essential for reservoir conduit systems which incorporated an underground chamber and inclined bridge-like constructions by a progression of arches.

B) Classification of Tunnel Based on the Alignment

1. Off Spur Tunnel: ( Types of Tunnels )

It is built or constructed for smaller lengths to move past minor obstructions where curved can’t be permitted.

2. Slope Tunnel: ( Types of Tunnels )

A tunnel constructed in steep and narrow hills for economic and safe operations of roads and railways are known as Sloping Tunnels, This type of tunnel is also mainly used for transportation Purposes.

3. Base Tunnel: ( Types of Tunnels )

It is built or constructed in the valley along the normal or normal slope. It is otherwise called Saddle Tunnel. It is utilized for transportation by the construction and development of rail route tracks and roadways.

4. Spiral Tunnel: ( Types of Tunnels )

Spiral or Winding tunnel provided to increase the length of the tunnel to avoid steep slopes in difficult and narrow valleys. Tunnels are provided in a narrow or restricted valley in the form of loops in the interior of the mountain to increase the length of the tunnel to keep away from steep slopes.

C) Classification of Tunnel Based on the Shape

1. D Shape Tunnel: ( Types of Tunnels )

It is utilized where there is a risk of failure because of outer pressure because of loosening unstable soil or water. It is the most appropriate for subways. These kinds of tunnels rooftop likewise called segmented rooftop takes up all the load and disperses it to the straight walls.

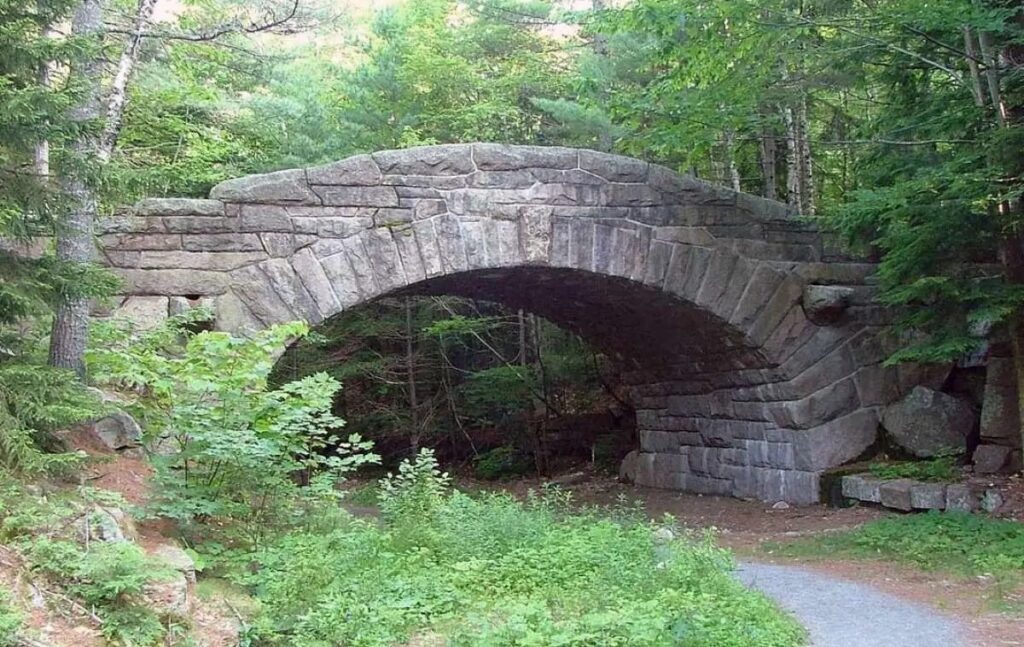

2. Horseshoe Shaped Tunnel: ( Types of Tunnels )

It has a semicircular rooftop with an arch on the sides. It has the combined benefit of a D shape and circular tunnels. By and large, it is utilized in railways. They Can endure internal and outer pressure.

3. Rectangular Shaped Tunnel: ( Types of Tunnels )

It is utilized for hard rocks. It is very expensive and utilized by pedestrians. They are for the most part suitable for pedestrian passage.

4. Circular Tunnel: ( Types of Tunnels )

It has strong resistance against outside pressure because of water. It is preferred on soft or delicate grounds. It is utilized for the transportation of oil and for laying sewage pipelines. It is the most grounded among all the shapes and economical as well.

5. Egg-Shaped Tunnel: ( Types of Tunnels )

Egg-shaped types of tunnels are the most ideal for sewage lines as it is having a self-cleaning velocity in a dry climates. Egg-shaped tunnel can resist both inside and outside pressure.

6. Saddle or Base Tunnel: ( Types of Tunnels )

These are constructed in the valleys along the regular or natural slope. They are primarily constructed for transportation purposes. Rail line tracks and roads can be constructed through these saddle tunnels. They are one of the primary kinds of passage for transportation.

7. Elliptical Tunnel: ( Types of Tunnels )

The more modest cross segment at the base keeps up with flow at the expected self-cleaning velocity, they are used in grounds contrasted differently in relation to rocks and these tunnels go about as water sewage conditions. Elliptical tunnels are challenging to construct.

D) Classification of Tunnel According to the Purpose

1. Traffic Tunnels: ( Types of Tunnels )

A traffic tunnel is typically adopted as a convenient and cost-effective alternative to provide a direct transportation link between two places isolated by inconvenient obstacles such as mountains, slopes, water bodies, or even densely populated regions in the metropolitan urban communities.

2. Conveyance Tunnels: ( Types of Tunnels )

These types of tunnels incorporate sewer tunnels, water supply tunnels, hydro-electric power tunnels, and so on.

How does a Tunnel Boring Machine Work?

A tunnel boring machine consolidates a shield and tailing support mechanisms. The front end of the shield comprises a rotating cutting wheel. In the driver’s seat, there is a chamber where the excavated soil is either blended in with slurry or left for what it’s worth.

The chamber comprises hydraulic jacks supported by the end part of the tunnel which helps in pushing the TBM forward.

When a specific distance has been excavated a new tunnel ring is constructed with the assistance of an erector. An erector is a rotating system that picks the concrete segments that are pre-casted and placed in the expected area.

Mechanisms, for example, dirt removal, slurry pipelines, control rooms, and rails are additionally installed behind the shield inside the finished part of the tunnel.

Advantages of Tunnels

- Tunnels enable rapid yet unhindered transport in large congested areas.

- Tunnels shield the system (rail line track, thruway, sewage line, oil line, respectively) under which it is built from changing weather conditions including snow, haze, etc. Thus, tunnels limit device operating costs.

- Tunnels forestall issues with surface life including traffic all through construction

- Tunnels safeguard the device from damage by bombs during the war.

- Sooner or later, tunnels have demonstrated less expensive to cross the mountain or river than open cut or bridges

- In its most heavily developed metropolitan area, underground rail or highways is the most secure decision for the accessibility of modes of transport.

- In soft rock, the tunnel construction became least expensive than that of the open-cut because of the significant amount of drops, respectively.

- Tunnels gets away from an unsafe open-cut close to the structure

- Tunnels are likewise proven economical to convey publicly owned utilities like water, power, sewers, etc.

- Except if the tunnels are equipped with a simple gradient, the transport expenses can be limited.

- The protection of tunnel construction additionally improved tremendously on account of the high-level present-day construction process.

- The reduction of distance tunnels has demonstrated to be affordable

- It diverts water for power generation and makes fast gradients in bumpy territory resulting in the high velocity of vehicles.

Disadvantages of Tunnels

- There is something else entirely to the underlying speculation of tunnel construction.

- The construction of tunnels requires skilled labor and high-level proficient oversight.

- The design of tunnels incorporates the production of sophisticated and specialized machinery.

Conclusion

The objective of tunneling is to stay away from the disturbance between surface life and traffic by an underground passage. Tunnel construction makes transportation simple and it is likewise a treatment measure against any geohazard in sensitive regions. Tunneling is a complicated process, particularly when it is being designed to mend natural hazards. It is one of the most complex constructions for any civil architect as there are geological features including, thrust zones, district, folded rock sequence, rock cover, the entrance of water, elevated degree of seismic movement, the entrance of gases, geothermal gradient, and many more.

Content Source: – civiljungle, readcivil, geo-xchange

Image Source: – waterproofmag, intechopen, mapfreglobalrisks, tunnel-online, mining, northeastmaglev, atlasobscura, ostindia, flickr, stonearchbridges, pinterest, kpstructures