5 Types of Spark Plugs: Working, Construction and Maintenance [Complete Details]

What is a Spark Plug?

Types of Spark Plugs: Working, Construction and Maintenance :- On the basis of how ignition takes place, engines are divided into two types- spark ignition engine and compression ignition system. The device used in spark ignition system, to ignite the compressed air fuel mixture in the spark ignition engine is called spark plug. As the name suggests, it produces an electric spark to ignite the mixture.

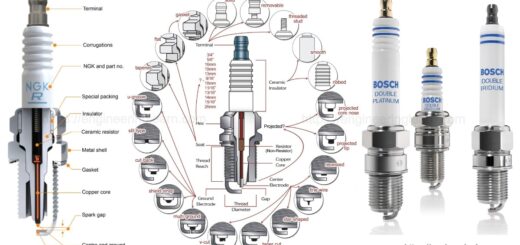

Construction of Spark Plug

Spark plug consists of broadly following parts:

1. Insulator

It is made of alumina of highest level of purity. Role of insulator is to protect and insulate the parts of spark plug from very high temperature of combustion chamber and to prevent escape of high voltage from the electrodes.

2. Terminal

It is connected to a high tension cord. High voltage current flows through this cord from the ignition system.

3. Ring, Packing Washer

It helps in keeping spark plug housing and insulator fit tightly with each other.

4. Center Shaft or Stem

It ensures the flow of high voltage current from terminal to the center electrode without significant losses.

5. Spark Plug Housing

It is an outer shell that surrounds the insulator. It supports the insulator and helps in the installation of spark plug in the engine.

6. Glass Seal

It helps in maintaining air tightness between insulator and center shaft.

7. Gasket

Threading on this helps the engine and the housing fit tightly with each other.

8. Electrode

There is a center electrode made up of special nickel alloy and with copper sealed at the center of it to increase the thermal conductivity.

9. Center Electrode

Center electrode is generally made up of a special iridium alloy. It is a rare and precious metal just like platinum and it reduces the requirement of voltage to ionize the air between the electrodes and produce spark.

10. Ground Electrode

It provides the necessary 0 volt potential for a good potential difference in order to produce electric spark.

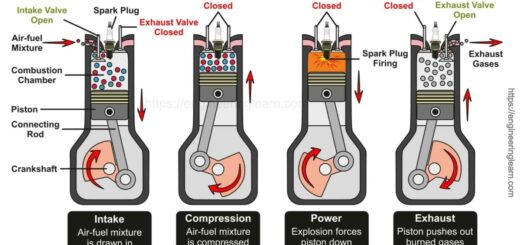

Working Principle of Spark Plugs

Spark plug is connected to an ignition coil or magneto. This ignition coil or magneto produces a very high voltage current. A very high potential difference is generated between the center electrode and ground electrode when the high voltage current flows through the coil. There is no current flow between the two electrodes initially, as there is no contact between them. But, as the voltage of the current flowing increases, there is ionization of the gases in the gap between the center and ground electrode.

When this voltage/potential difference between the two electrodes is more than the dielectric strength of the gases, the gases become completely ionized and current flows through them, producing the spark. A surge in the current flowing, also increases the temperature of the spark to as high as 60,000 K.

Types of Spark Plugs

Basically, the classification of spark plugs is done on the basis of :

i) The materials used in their construction

ii) Operating temperatures

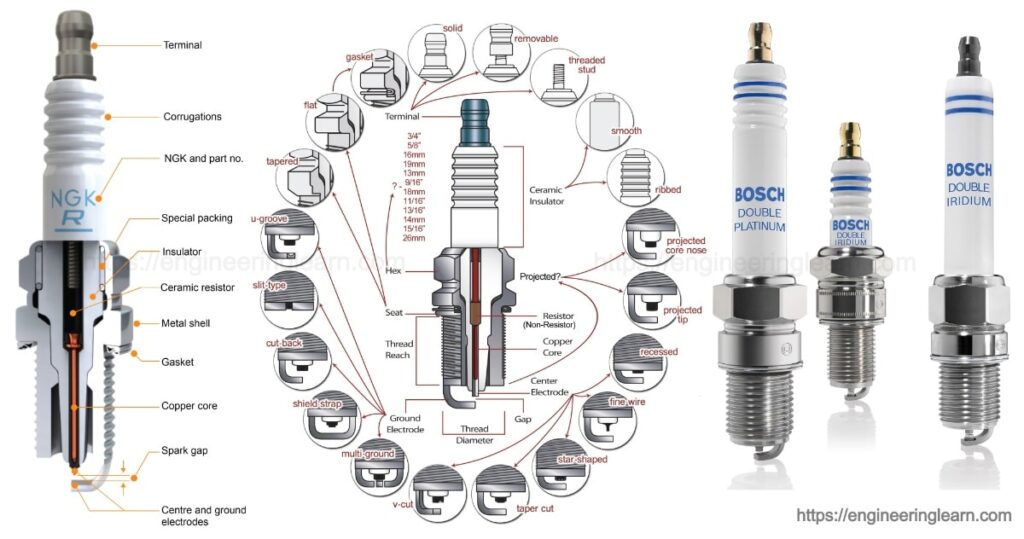

Following are the commonly used types of spark plugs on the basis of the materials used in their construction:

- Copper spark plugs

- Platinum spark plugs

- Iridium spark plugs

- Double platinum spark plugs

- Silver spark plugs

1. Copper Spark Plugs: ( Types of Spark Plugs )

The most popular spark plugs available in the market are copper spark plugs. A nickel coating is used in these spark plugs as electrode, but the core of that electrode is fitted with copper. While copper offers very high electrical conductivity and sufficient spark even in the adverse conditions from turbo chargers, it has a problem of melting down in high temperature conditions. Thus it is used along with a nickel coating. Most high performance vehicle manufacturers use this spark plug because of its efficiency.

2. Platinum Spark Plugs: ( Types of Spark Plugs )

As the name suggests, this spark plug uses platinum in its construction. The center electrode is made up of platinum. Platinum is a precious metal. This makes these spark plugs very expensive. It must be noted that platinum is harder than nickel. This increases the overall durability of the spark plug. In other spark plugs, as the center electrode experiences wear and tear with time, the gap between the electrodes increases. But in these spark plugs, the center electrode made up of platinum, does not have any such problem. These spark plugs are more resistant to carbon buildup.

3. Iridium Spark Plugs: ( Types of Spark Plugs )

When there is a requirement of high power output from the engine, iridium spark plugs are used. They offer a very efficient spark, thus ensuring complete combustion and subsequently smooth running of the engine. These spark plugs also have a longer lifespan as compared to copper spark plugs. The only drawback of these spark plugs is their very high price.

4. Double Platinum Spark Plugs: ( Types of Spark Plugs )

They are same as platinum spark plugs. The only difference is that they have both their electrodes made up of platinum, i.e. ground electrodes as well as center electrode, both are made up of platinum.

5. Silver Spark Plugs: ( Types of Spark Plugs )

As understood from the name itself, these spark plugs are made up of silver. They offer high performance and also excellent thermal conductivity. They were generally used in the European high performance vintage cars and motorcycle engines. Their only drawback is shorter lifespan and low durability.

Along with exhaust gases and walls of the engine cylinder, the spark plugs also help in dissipating the heat generated during a combustion cycle. Thus, based on amount of heat dissipation and operating temperatures, spark plugs have another classification. They can be of two types:

A) Hot Spark Plugs

They operate in range of high temperatures. The reason behind this name is that they dissipate lesser heat because of their lesser ceramic area. This keeps the electrodes and the tip hot and thus, any carbon deposits are burnt away and do not stay for long.

B) Cold Spark Plugs

High performance engines run at high temperatures by default. Thus, if we use hot spark plugs with them, they can cause pre-ignition of the fuel, i.e. the air fuel mixture will get ignited before the spark is even produced. This is because of the glowing carbon particles burnt away by the hot spark plugs.

Thus we need a spark plug which dissipates good amount of heat and operates in a lower temperature range. These spark plugs have a larger ceramic area and thus more heat is dissipated. But the drawback is that there’s carbon deposition on electrodes from time to time. Thus for optimum engine performance, correct type of spark plug should be used.

Maintenance of Spark Plugs

1. Right Choice of Spark Plugs

For a high performance engine, we need a cold spark plug. This is because; if we use a hot spark plug, there will be problems like pre-ignition. Under high temperature circumstances the electrodes can get molten off too. If we use cold spark plug with a low performance engine, it will quickly dissipate the heat, thus causing a delay in the spark. Thus the choice of spark plugs should be made on the basis of the engine performance.

2. Cleaning off the Electrodes

The sparkplug should be carefully removed from the terminal using a special wrench made for spark plugs. Then, it should be immersed and soaked in a suitable thinner liquid, like petrol, diesel or isopropyl alcohol. Then the hard crusted deposits should be removed off the spark plug electrodes using toothbrush or wire brush, in case they are hard to remove using toothbrush.

3. Maintaining a Suitable Gap Between the Electrodes

If there is too much gap between the center electrode and ground electrode, the spark will be weak. In case the gap is too small, there will be no spark at all. Thus, the user manual of the vehicle should be checked to find out the optimum gap between electrodes and the spark plug should be checked time to time to see if there is desired gap between the electrodes. A coin or a wire can be used to measure the gap. In case the gap is more than what is desired, necessary adjustments should be made very carefully. Special care is required with respect to the ground electrode, because it gets snapped off very easily on impact.

4. Cleaned of Spark Plugs

The area where the spark plug is mounted should be cleaned from time to time. Accumulation of combustion debris here can cause misalignment of spark plug. Thus it should be cleaned before mounting the spark plug.

Image Source :- pulstarpulseplugs, mechanical-engg, bosch