Types of Lubrication System: Definition, Purpose, Application, Advantages & Disadvantages

Types of Lubrication System :- Lubrication is a process which is done in order to control the effect of friction and to decrease the level of wear and tear caused by moving surfaces. There are numerous substances that can be used to lubricate the machinery or its parts, however, the most effective amongst them are mostly Oil and Grease.

Here is a brief and general description of lubrication, which has many different aspects and applications, including the installation of a specific lubrication system and also the types of lubricant which can be used.

What is Lubrication System?

A lubrication can also be termed as a Centralized lubrication system which is defined as the accurate and precise amount of a particular lubricant which is delivered till a specific point and that to at the exact time by using the right method, while the machine is in the operational mode.

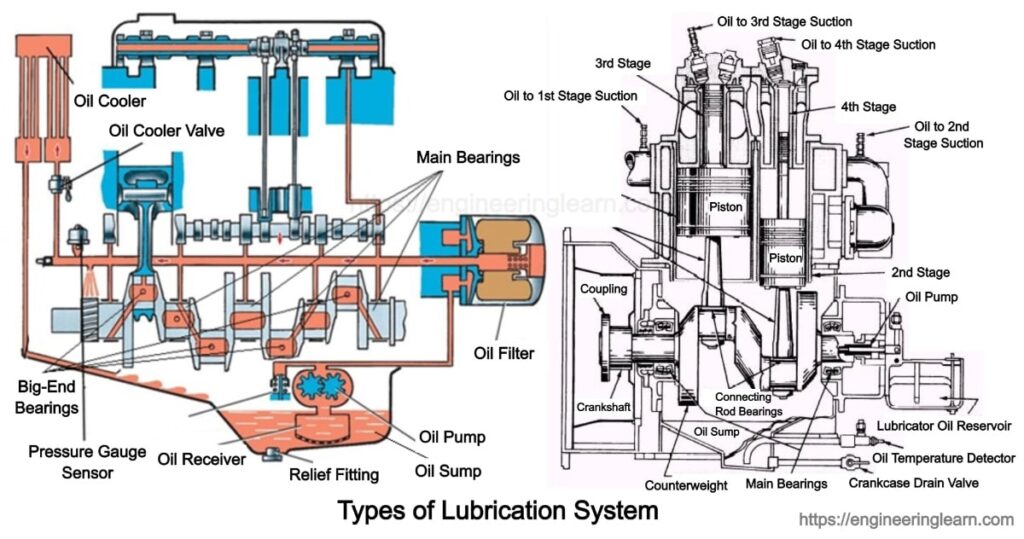

The structure of any lubricating system includes a pumping element, lubricating tank, electrical control device, dividers, distributors, and distribution lines which includes pipes and fittings.

Purpose of Lubrication Systems

The main purpose of an effective lubrication system are described below:-

- Used to reduce the friction and wear and tear amongst the components of the machinery.

- It reduces the energy and consumption of lubricant.

- Lubrication can reduce the generation of heat which can result in maintaining a consistent temperature.

- Used to reduce the noise made by the increased friction level.

- Foremost is that it reduces the damage from corrosion and also avoids the insertion of contaminants at the work site.

Moving ahead, it also makes sure about the advantages which generally increase the efficiency of the machine, improves the accuracy of the work, increases the life of the machine and reduces the maintenance and repairing cost.

Types of Lubrication System

Various types of lubrication systems have been developed in the few years and there are still upcoming, that are based on the particular requirement of the machinery and the different industrial sectors.

Below mentioned are the five main areas of lubrication systems solutions:

1. Grease Lubrication System

In this system, the greasing pumps are used to properly provide the amount of grease to the lubrication points. The main system that is used for grease lubrication is dual line and progressive system.

The Dual Line system is found having a quite modular design which is allowed for simple configuration and is also preferred for the expansion system. This system is mostly suitable for industries with large machines and multiple lubrication points like iron and steel industry, cement plants, platforms, large cranes, cargo handling equipment etc.

A developing system properly distributes the flow of grease pump into separate outlets with the help of a progressive spool arrangement. This technology allows for the quick replacement of an element without interrupting the operational work cycle. The condition is usually suitable for small, medium and large sized machines which requires a complete control of plant operations.

2. Lubrication Oil System

In case of the total loss lubrication, oil or fluid grease creates a thin film of oil which mostly protects the parts of the machinery. It is renewed quite frequently with an automated lubrication system that is done using an electric oil pump.

The main systems which is involved in the oil lubrication process is the single line system and the 33V system.

Single Line lubrication system

The Single Line lubrication system refers to an easy and effective system which offers various solutions for a variety of required applications. The system is suitable only for small machines which are being operated in a protected environment with a very few lubrication point and limitation of space, tools, woodworking machines, textiles machinery, printing machines etc.

The 33V system refers to a precise system which is used for dosing only the specific amount of oil directly to the points where the lubrication is needed. The system is suitable for all the types of small and medium sized machines like, woodworking machines, textiles machines, presses etc.

MQL (minimum quantity lubrication)

MQL (minimum quantity lubrication) is a system or can also be termed as a new technology which can be replaced with the traditional or pure oil fluid systems in a machining environment. One must know that a controlled compressed air stream can carry minimal quantity of cutting oil in an aerosol through the tool lubrication.

MQL lubrication system is found to create ultra-fine aerosol oil particles which are generated by the new and innovative vortex technology. The system is suitable for the high in demand and highly efficient near-dry machining applications which require an external and internal minimal quantity lubrication to work properly.

3. Air-Oil Lubrication System

The quantity of oil is pulled apart by the current of air in the narrow tube. Then after it gets transported in the direction of the lube point. The bearing is consistently supplied with fine droplets of oil from the outlet of the nozzle. The carrier air leaves the bearing completely oil free.

This system inculcates a controlled air-oil stream which is utilized for both cooling as well as carrying small quantities of air-oil particles to the lubricating points. The system is mostly suitable for large machines which are installed in heavy industry.

Advantage of Air-Oil Lubrication System

- It reduces abrasion and skidding

- Protects the surfaces from being corroded

- Protects the contact area from contamination

- Enhances the performance of the machine

- Higher dependability

- Less consumption of lubricant

4. Spray Lubrication System

The lubricant which is transported by the pump is conveyed along the line of a nozzle. This lubricant gets mixed with the supply of a compressed air inside the nozzle which depends upon the requirement of the site. This lubricant can then be either sprayed slowly and gradually or continuously in a properly defined quantity. Patterns of the spray and its width can be depend upon the medium, air pressure, temperature and air throttle. The amount of lubricant required can be reduced to a good distribution while spraying the lubricant.

Application of Spray Lubrication System

Spray lubrication systems is used in large gears in driers, and on toothed racks in the general mechanical system. For instance substances like grease, oil, water and emulsion are sprayed commonly. These lubrication systems are initially termed as total-loss lubrication systems. The spray system is not only suitable for reducing the effect of friction but is also used for spraying work pieces to cool or protect against corrosion. Areas with high-viscosity media can also be sprayed whose usage can be decreased to an ambient temperature being minimum at -25 °C with an optional heating system.

Advantage of Spray Lubrication System

- It is used for providing exact lubrication control

- The use of oil is reduced up to 90%

- Reduces the reject rates

- Extends the life of the tool

5. Oil Mist Lubrication System

Oil Mist lubrication is a centralized system in which the energy of a compressed gas is used to atomize the oil. The oil is then conveyed by the impact of air that too in a low pressure distribution system in order to multiple the points of application of the lubricant. The air which is compressed is passed through a venturi. The Oil is drawn off from the reservoir by the consistent flow of air which is atomized into a fine spray. The nozzle of the venturi causes the larger oil particles to return to the reservoir. The remaining mixture of the air and oil is the oil mist. Oil Mist contains oil droplets with about a diameter of 1 microns or 0.00006 inches, which can easily be conveyed through the distribution pipe with an average velocity up to 24 feet per second.

The oil particles are wetted out upon bearing surfaces by rotating it at a sufficient speed to cause adherence and form large size of the drop and as there are no moving parts in the oil mist generator, due to the system pressure being low. Therefore this is a reliable method of lubrication. This system can also be interlocked with the operation of the machine or the system of alarm in order to ensure proper working.

Purpose of Oil Mist Lubrication Systems

The main purpose of oil recirculation is to supply and provide lubrication to the bearings and gears which reduces the scope of wear and tear amongst the parts. The electric pump which is used to keep an appropriate lubricant pressure in the main line where the flow of oil is also measured and kept regulating.

Another lubricating system can be added to the previous which is mainly used for the oil refineries. The particles delivered directly to the bearings and metal surface of the machineries are to maintain a high quality and cost-effectiveness of the lubrication solution.

6. Splash Lubrication System

This type of lubrication system is mostly used in engines of the motorcycle. The technique is mostly used in lawn mowers, motors or outboard boat engines which should have an enough quantity of oil in the trough to lubricate the machine completely.

Components of Splash Lubrication System

- Crankcase: This component is used to store the oil which is then passed through the oil gallery to ensure proper lubrication.

- Oil Strainer: The oil strainer is used to filter the impurities of the oil which are present in it, in order to prevent any blockage at any part and ensure efficient working.

- Oil Pump: This is the major part of splash lubrication system as it is used to shift the fluid from the crankcase to all the other parts of the engine.

- Oil Troughs: Oil troughs are found just below the scoop of the piston in such a way that whenever the piston is in a reciprocating motion, the scoop of the piston lifts the oil from the oil troughs in such a way that the oil reaches all the parts of the piston to lubricate it effectively.

- Crankshaft: It is the part where the reciprocation motion of the piston gets converted into the rotatory motion of the crankshaft inside the cylinder of the engine. The power which is obtained from the crankshaft gets transmitted to all the parts of the vehicle.

- Scoop: The scoop is connected at the end of the piston. The scoop of piston lifts the oil from the oil troughs in such a way that the oil reaches all the parts of the piston for proper lubrication.

- Piston: The piston plays a very role in the engines. It is present inside the engine cylinder and is responsible for converting the reciprocation motion into rotatory motion of the crankshaft.

- Cam Shaft: The camshaft consists of cams which are used for operating the valves in the internal combustion engine.

- Oil Pressure Gauge: The oil pressure gauge is used to measure the amount pressure of oil in the engine cylinder.

How to Wisely Select Lubrication Systems?

Types of Lubrication System :- For selecting the best lubrication solution here are the references which are necessary and help in determining the production needs of the machinery. Scroll down to learn

- Type of lubricant like oil, grease etc.

- Types of lubrication system: total loss, air-oil, grease, recirculating oil

- Points to lubricate: number, position, type

- Gap amongst the pump and various lubrication points

- Quantity of lubricant: per single point or proportionality between the points.

- Type of supply: manual, electric, pneumatic etc.

- Management type: manual, automatic with or without electrical panel

- Particular condition: Temperature