What is Lintel? 13 Types of Lintels, Functions, Advantages & Disadvantages [Explained with Details]

![What is Lintel? 13 Types of Lintels, Functions, Advantages & Disadvantages [Explained with Details]](https://engineeringlearn.com/wp-content/uploads/2022/12/Lintels-1024x539.jpg)

Introduction

What is Lintel? 13 Types of Lintels, Functions, Advantages & Disadvantages [Explained with Details]: – A lintel is an inescapable part of buildings. At the point when we need to make an opening like entryways and windows in the building, we use lintel over the opening as a straightforward solution. Despite the fact that lintel construction is simple and is commonly utilized.

What is Lintel?

A lintel is one kind of beam which is used to support the above wall or partition material when openings like doors or entryways, windows, etc are important to provide a building structure. The essential function of the lintel is to take loads originating from the high wall and transfer its help to the side walls.

The lintel beam for the most part ends in the masonry wall to pass the weight conveyed by them onto the masonry walls, and its width is equivalent to the wall width. The lintel can similarly be used as an enlivening compositional component.

Functions of Lintel

- The lintel is a beam put over openings like windows, entryways, and different openings to sustain the load from the structure over the building.

- The lintel is responsible for the structure’s stability.The lintel likewise serves another crucial purpose.

- The lintel beam disseminates the applied weight from the superstructure to the side walls.

- The lintel’s purpose is to safeguard the doors and windows from the elements.

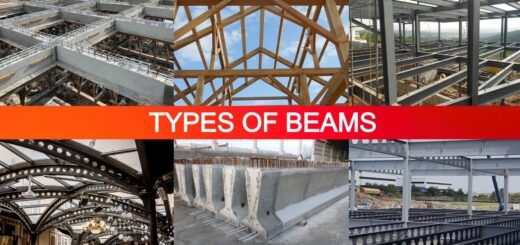

Types of Lintels

1. Timber Lintel: ( Types of Lintels )

Timber lintel is the most common Lintel used. They’re actually utilized in hilly or sloping locations where timber planks are in plenty. They are, in any case, getting rid of a range of more current structures. They can’t endure high loads, especially bending strains. The designer chooses to sandwich the beam board in mild steel plates with huge windows or gaps from top to bottom. They become more durable or sturdy and enduring accordingly.

The steel bolts hold the timber lintel beam in place, which is more costly, less durable, and inclined to fire. The most serious downside of a timber lintel is its vulnerability to fire. It is fragile and less durable. It requires sufficient ventilation. Any other way, the rot will destroy the beam.

2. Stone Lintels: ( Types of Lintels )

These are suggested exclusively where the stone is accessible in abundance and the structure is made of stone masonry. The stone lintels may likewise be utilized in buildings that comprise of stone-facing. Stone lintels are made of slabs of stones of adequate length without imperfections either in a single pieces or a blend of additional pieces. Stone, being of poor tensile length, can’t endure the cross-over stresses. Thus stone lintels ought to never be utilized for an opening surpassing a 1-meter span except if furnished with alleviating curves above, any other way, they would require unusually profound lintel.

It is hard to obtain the slabs of stones of adequate length and depth, liberated from imperfections or flaws. Also, the stone lintels end up being expensive as they require a good deal for quarrying, transportation to a worksite, dressing, and special handling on the site because of their weight.

3. Brick Lintels: ( Types of Lintels )

These are utilized to traverse little openings (short of one meter) with light loading. They for the most part comprise bricks that are normally laid on end and sometimes on the edge.

The brick lintel is constructed over temporary wood support known a turning piece. Bricks with frogs are more suitable and reasonable for the construction of lintels as they form juggles when bounded and thus have more shear resistance toward the end joints. The structure formed by utilizing frog bricks is named ‘joggled brick lintel’. Bricks ought to be hard, well-burnt, free from imperfections like knots, cracks, and defects, and with sharp and square edges. The depth of the brick lintels, which varies with the size of opening and presence of brickwork, ought to be a multiple block courses.

4. Wooden Lintel: ( Types of Lintels )

Wooden lintels may either comprise a solitary piece of timber or built-up segments of at least two pieces held together by bolts at reasonable stretches. These built-up lintels are for the most part utilized for larger spans. The wooden lintels are placed, with the proper bearing at the ends, to traverse across the openings. Afterward, the masonry is constructed over it. Wooden lintels are comparatively weak, therefore, easing or releasing arches of brick or stone are provided over them. The space between the lintel and the arch is loaded up with a brick or stone core.

Wooden lintels ought to be made of sound and hard timber, similar to teak, rosewood, or sal. In any case, they are probably going to be obliterated by fire and decay or may bend under a heavy load. The amount of bearing of lintel ends ought to be adequate (generally 15 to 20 cm). This horizontal structure ought to rest on mortar to offer firm and uniform support to the structure.

5. Concrete Lintels: ( Types of Lintels )

These days, the most commonly utilized types of lintels are concrete lintels which are made of concrete cement. They are of two sorts.

- Plain Concrete Lintel

- Reinforced Concrete Lintel

A) Plain Concrete Lintel

These are prepared with plain concrete beams. They are devoid of any steel bars; subsequently, they are not useful for heavy loads. They are made for just a span of up to one meter.

Concrete areas of strength for their compression however weak in tension. Subsequently, these lintels are not utilized for a more drawn-out range.

B) Reinforced Concrete Lintel

RCC lintels are constructed usually with a substantial blend having proportions 1:2:4 (1 concrete: 2 sand: 4 broken stone aggregate, by volume), supported with mild steel bars.

The plain concrete is unsuitable for lintels as it is similarly powerless in tension. Consequently, lintels are normally strengthened by utilizing mild steel bars or another type of support. The amount of reinforcement relies on factors, in particular the width of the opening, the span of the lintel, and the total load to be conveyed by the lintel.

Types of RCC Lintels

RCC lintels may be either pre-cast or cast in-situ:

A) Pre-Cast RCC Lintels

Pre-cast RCC lintels are preferred for small spans up to 2 meters or somewhere in the vicinity. They are cast in wooden molds and restored well ahead of time. Pre-cast lintels turn out to be reasonable as a comparable shape can be used to set up different lintels. Besides, the utilization of pre-cast RCC lintels guarantees speedy construction as it doesn’t require additional time for curing or eliminating props. Nonetheless, while laying a pre-cast lintel, exceptional consideration ought to be practiced to see that the marked face is on the top or upper side.

All pre-cast lintels are set apart with tar or paint at the top in the wake of pouring cement in the mold to distinguish it from the base. This is essential since supposing that the faces are reversed in position or the reinforcement is reversed, there will be a structural failure, jeopardizing the structure.

B) Cast-in-Situ Concrete Lintels

For larger spans, the lintels ought to be cast in situ. For cast-in-situ RCC lintels, erection of centering, placing of support or reinforcement, and concreting is done as usual. The closures of the bars are hooked to build the grip or bond between them and the concrete.

6. Reinforced Brick Lintels: ( Types of Lintels )

These are utilized to span small openings (less than one meter) with light loading. They by and large comprise bricks that are typically laid on end and occasionally on the edge. The brick lintel is constructed over temporary wood support (for example going about as centering) known as a turning piece. Bricks with frogs are more suitable for the construction of lintels as they form juggles when limited and thus have more shear resistance toward the end joints (more noteworthy strength).

The structure formed by utilizing frog blocks is named ‘joggled brick lintel’. Bricks ought to be hard, well-burnt, free from deformities like lumps, cracks, and defects, and with sharp and square edges. The profundity of the block lintels, which fluctuates with the size of the opening and the presence of brickwork, ought to be different from block courses. Door frames and window frames ought to be fixed with a setback of 2.5 cm from the outside essence of the wall.

7. Standard Cavity Steel Lintel: ( Types of Lintels )

This is the most commonly utilized in construction. The average size range would be around 98 mm comprising of blocks or bricks. They are the forerunners in the construction world for their load-bearing capacity. They are exceptionally intended to convey the heavy stone workloads. They are known for their solidarity and soundness. In opposition to the conviction, they are not difficult to install and have an appealing exciting finish as well. One more great element is its strength even with thermal changes. Thermal efficiency is a significant factor to consider for areas exposed to outrageous temperature varieties.

8. Steel Lintels: ( Types of Lintels )

These lintels, comprising of rolled steel joists implanted in concrete, are utilized over large openings, especially when they have a support a heavy load of solid walls in the position, for example, shop-fronts, and bay windows. These are sometimes called bressummers. In some cases, lintels, comprising of steel angles or direct segments in concrete, are utilized for small spans and light loading, especially when there is no space above to oblige an arch or for making a relieving arch. Being very costly, these are confined to special cases only.

9. Wide Inner Leaf Steel Lintels: ( Types of Lintels )

These types of stones accompany the exceptional additional feature of having an inward leaf that can hold the extra block work that necessities support. These types of lintels are known for supporting block work up to a length of around 160 mm. They are quite popular in the masonry field. They are accessible in various lengths with different additions in various size ranges.

10. Wide Outer Leaf Steel Lintels: ( Types of Lintels )

This type of lintel accompanies an outer leaf. The benefit they have is that they support stone on the outer leaf. Stone is more extensive than brickwork. Combined lintels can uphold the additional width which is accomplished by utilizing stone. It is very easily installed and can likewise be detached when not needed. This outer leaf is exceptionally designed when the external stone is utilized.

11. Short Outer Leaf Steel Lintels: ( Types of Lintels )

They have an outer leaf with a range of around 75mm and are specially designed to support stonework and not brickwork, unlike their other counterparts. Reconstructed stonework at building construction sites is normally supported by this sort of lintel. The most extreme overall strength length begins with the size scope of 600 mm and at times, upwards, offering that genuinely necessary additional length. The galvanized completion further improves the robustness of the end product. These kinds of lintels are popularly known to support concrete floor loads and point loads, making it very important in the masonry field.

12. Cavity Lintels: ( Types of Lintels )

Cavity lintels are designed, as the name demonstrates, to fit into the cavity of an outside wall and can be utilized to span both entryway or window openings. The wedge shape assists with carrying any water in the cavity to the outside as opposed to allowing it to penetrate inside. Among all lintels, reinforced concrete lintels are most widely utilized these days to span openings. This is on the grounds that different materials have become outdated because of numerous downsides. For example, the wooden ones are inclined to decay, the stone ones are expensive and may have defects, and the steel segments are wasteful and become loose when exposed to the sun, and furthermore not free from corrosion.

13. Specialist Lintels Catnic: ( Types of Lintels )

Most applications won’t require anything besides a concrete lintel or standard steel. Be that as it may, there are different types of opening that could require a specialist lintel. These are accessible in the market as catnic lintel, named after its assembling organization.

These kinds of lintels incorporate corrosion-resistant coating and thermal insulation so that less heat is lost through these undeniable breaks in the wall structure. Catnic lintels accommodate a wide assortment of purposes, including under-eave, pit wall, Corner, timber frame, and rock solid or extreme load lintels.

Advantages of Lintel

- They look less complex and are not difficult to assemble.

- The Excessive load isn’t applied over the ending supports of lintels. Consequently, they are not required to be constructed so firmly.

- Centering of the lintel is simple, and frameworks are likewise inexpensive

- They can bear a high amount of load in the event that the load is coming consistently.

- They are fragile and look simple.

Disadvantages of Lintel

- The lintel will deform by sagging in the center in light of the fact that the underside is under tension and the topside is under compression.

- The limited weight that can be held up.

- The Wight of each piece

Conclusion

A lintel is a significant part of a Building’s structure. It is the upper part of any window, entryway, or opening (like arched walkways). Its fundamental purpose is connected with carrying loads and transferring them adequately to not cause any damage to the overall building structure. These are the various varieties of lintels and their characteristics. All lintels have distinct features, and the type of lintel is chosen by the type of building, its design, and the region where it is taking place.