Hydraulic and Pneumatic | What is Hydraulics? | What is Pneumatics? | Difference Between Hydraulic and Pneumatic

Introduction

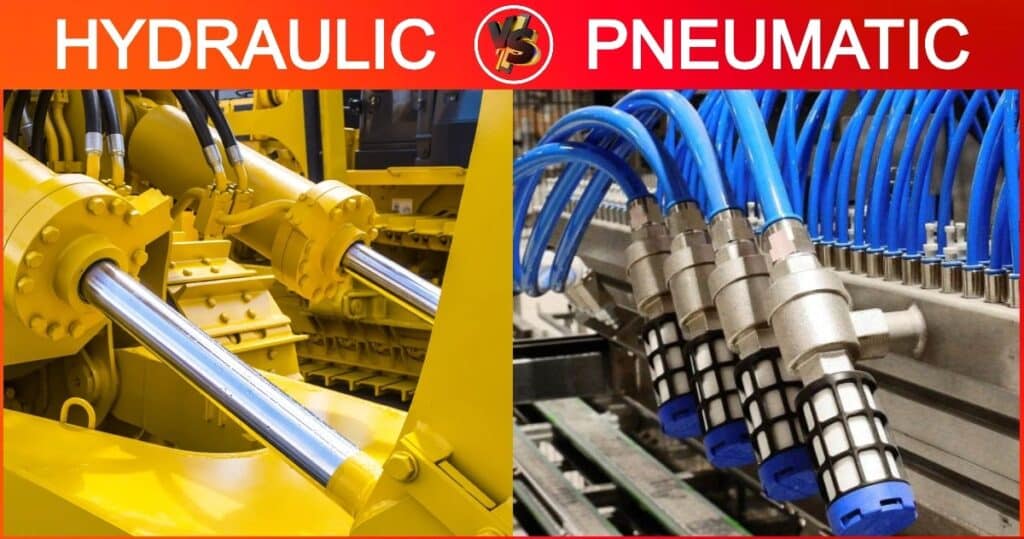

Hydraulic and Pneumatic | What is Hydraulics? | What is Pneumatics? | Difference Between Hydraulic and Pneumatic: – Pneumatic and hydraulic systems have numerous similarities. Both pneumatic and hydrodynamics are applications of fluid power. They each utilize a pump as an actuator, are controlled by valves, and use fluids to transmit mechanical energy. Pneumatic utilize an effectively compressible gas like air or different kinds of suitable unadulterated gas while hydraulic utilizes generally in-compressible fluid media like hydraulic or mineral oil, ethylene glycol, water, or high-temperature fire-resistant fluids. Neither kind of system is more well known than the other on the grounds that their applications are specific. The load or the force that you want to apply, the output speed, and energy costs decide the sort of system you really want for your application.

A) Hydraulic System

What is Hydraulics?

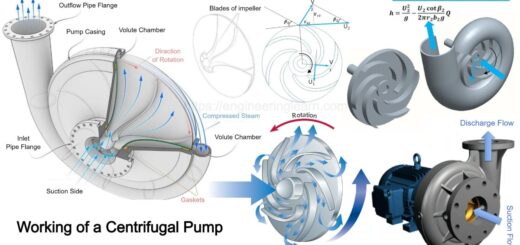

Hydraulics is utilized for the generation, control, and transmission of power utilizing pressurized liquids. It is a technology and applied science including mechanical properties and utilization of liquids. Hydraulic systems require a pump and, as pneumatic systems, utilizes valves to control the force and velocity of the actuators. The word hydraulics begins from Greek words hydor – water and aulos – pipe. The following equipment is required for a hydraulic systems: hydraulic fluid, cylinder, pistons, and valves that control the direction of flow, which is generally in one direction.

Hydraulic systems, unlike Pneumatic systems, are in many cases large and complex. The system requires more room in light of the fact that a container is required to hold fluid that flows through the system. Since the size of the system is larger, it requires more pressure; making it more costly than Pneumatic systems. Hydraulic systems are slower on the grounds that oil is viscous and requires more energy to travel through pipes. During planning and configuration, on the off chance that the production line or plant has a few pressure-driven machines, it is ideal to have a focal power unit to decrease commotion levels.

How Does a Hydraulic System Work?

Hydraulics depend on fluid power: hydraulic oil or water is utilized to transfer pressure applied at one point to another point. They can involve anything from hydraulic fluid from mineral oil to ethylene glycol to synthetic fluids to water. Because of the need to pump fluids hydraulic systems for the most part include reservoir tanks. These systems are typically more heavily built and occupy more room, however, they are additionally very strong.

Hydraulic systems range in complexity and size, however, there are a few parts essential to each system. These include a reservoir to contain the hydraulic or mineral oil utilized, pipes, a pump with a motor to push the fluid around, and valves that control the speed, bearing, and pressure of the hydraulic liquids. Furthermore, there is generally an actuator that transforms the liquid’s energy into force.

Applications of Hydraulic Systems

- Hydraulic systems are generally utilized in automation enterprises.

- In the automobile business, hydraulic systems are utilized in power brakes, power steering, suspension system, and so on.

- The missile launching system utilizes hydraulic system.

- The agricultural sector or rural sector utilizes the hydraulic systems. It is utilized in farm equipment like movers, plows, chemical and water sprayers, harvesters, and so on.

- One of the most well-known examples of hydraulic systems is jacks, lifts, cranes, and forklifts in material taking care of systems.

- It is likewise utilized in transportation frameworks like hydraulic lifts, winches, and above cable cars.

B) Pneumatic System

What is Pneumatics?

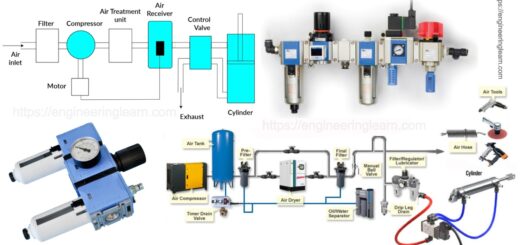

Pneumatic is a part of the engineering that utilizes compressed gas or air to affect mechanical motion based on the working standards of fluid dynamics and pressure. The field of pneumatic has changed from small handheld gadgets to large machines that serve various functions. Pneumatics systems are commonly forward by compressed air or inert gases. The system comprises of an interconnected set of parts including a gas blower, change lines, air tanks, hoses, standard chambers, and gas (environment). The compressed air is supplied by the compressor and transmitted through the movement of hoses.

The airflow is directed by manual or programmed solenoid valves and the pneumatic cylinder moves energy given by the compacted gas to mechanical energy. A halfway-found and electrically controlled blower powers chambers, air engines, and other pneumatic gadgets. Pneumatic frameworks are constrained by a basic ON/OFF switch or valve.

Most industrial pneumatic applications use pressures of around 80 to 100 pounds for each square inch (550 to 690 kPa). The compressed air is stored in beneficiary tanks before it is transmitted for use. The compressor’s ability to compress the gas is restricted by the compression proportions.

How Does a Pneumatic System Work?

Pneumatic works similarly to hydraulics, however, they use gas rather than liquid to operate, normally compressed air, which can be drawn directly from the environment around them. Air is generally filtered and moisture is taken out before it goes into the system to save internal corrosion. This utilization of a compressible, effectively obtainable medium changes the design of a pneumatic system a lot, including the addition of a compressor, something a hydraulic system doesn’t have.

A few older systems might require oil to lubricate their cylinders, which vaporizes into the mist to keep parts back from wearing. Be that as it may, newer systems use cylinders and valve seals made using materials like nitrite to avoid having to utilize lubricants.

Like water-powered(hydraulic) systems, pneumatic systems contain an air reservoir, valves, pipes or lines, and pneumatic actuators to switch energy over totally to force. A pneumatic system, nonetheless, will likewise include an air compressor to fill the system with an adequate amount of PSI to ensure the hardware capabilities.

Applications of the Pneumatic Systems

- Instruments used in the fabrication industry such as pneumatic drills, grinders, borers, riveting machines, nut runners, etc run on a pneumatic system.

- Vacuum suction cups are used for glass handling.

- Work-holding devices, clamps, and stoppers make use of a pneumatic system.

- It is additionally utilized in robotized machine tools, and numerically controlled (NC) machine apparatuses.

- Pharmaceutical, as well as the medical industry, makes wide use of pneumatic systems.

- The robotic industry makes wide use of pneumatic systems.

Difference Between Hydraulic and Pneumatic Systems

Any sort of modern-day construction or manufacturing or assembling application is most likely going to integrate one or all of three different types of power: electrical, water driven, or pneumatic.

While certain actuators and lifting devices can be simply electrical, utilizing a screw system, all things considered, you’ll utilize some type of fluid power.

Pneumatic provides fluid power through compressed air or gases. Hydraulic provides fluid power through compressed liquids, like oil or water. In picking one of the two, cost-viability, materials to be moved, accessibility of assets, and space are all factors to be considered.

#1. Strength: ( Hydraulic and Pneumatic )

Hydraulics is the most ideal choice for strength, on the grounds that the liquid medium utilized for its operation has a high mass density and is generally in-compressible. This implies that hydraulics can foster a lot more elevated levels of pressure, and can utilize that pressure to transmit the power that will drive your application. Industrial applications utilizing hydraulic power might order anything from 1,000-5,000 pounds for every square inch (psi) of pressure, while a few particular applications, for example, mining equipment or truly heavy lifting cranes can foster 10,000 psi or more.

The liquids used in pneumatic have low mass thickness and are effectively compressible. In certain conditions, gas or air can be compressed up to a few hundred psi, however, most mechanical applications depend on an operational pressure of just 80-100 psi. This implies that pneumatic systems are to a great extent unequipped for a lot bigger power presented by hydraulics, and are unsuited to the moving or lifting of heavy burdens. Compressed air is likewise dependent upon unforeseen pressure drops or fluctuations which can cause operations to become jerky or unsteady.

#2. Speed: ( Hydraulic and Pneumatic )

Compressed air has a high flow rate, which empowers the quick release of energy and rapid movement of moving parts like actuators. Pneumatic actuators can accomplish high cycle speeds and increased duty cycling, which delivers more prominent efficiency. The advantage of rapid cylinder movement is additionally enhanced by the accessibility of gear in tiny sizes, ideal for use in applications where scaling down is a priority.

Air has a much lower mass density or thickness and can flow significantly more rapidly and effectively through the pipework. One more benefit of the pneumatic system is that valves and cylinders can rapidly adjust their direction or take an alternate route by dumping their compressed air. This can be voided directly into the atmosphere and requires no further disposal.

Water and hydraulic oil have a lot more prominent resistance than air, with the viscosity of oil making it a lot more slow. Despite the fact that it will at last foster a more prominent level of force and keep up with steady pressure, it doesn’t have a similar speed as air movement and may take more time to get your system running. In case of a spillage or crisis, water-driven liquid may not be vented quickly to the climate, but rather should be rerouted back to its tank or reservoir.

#3. Hygiene: ( Hydraulic and Pneumatic )

Pneumatic systems prevail upon hydraulics in the field of hygiene, as the main thing that can leak out of your system is air. Within the system itself, the compressed air will be cleaned of oil, water or metal particles, and some other toxins, by the filtration unit. Pneumatic systems are by and large preferred by environmentally-conscious companies or those contemplating greener manufacturing practices.

You’ll likewise probably choose pneumatic on the off chance that you’re installing systems in a clean room, a drug lab, or the food and drink industry. In these conditions, there should be definitely no risk of contamination, so hydraulic systems are by and large off-limits as they might be susceptible to spillage.

Whether you choose water or oil in a hydraulic system, both of these may possibly leak out through faulty seals, valves, or worn hoses. This will contaminate your clean environment in spite of any protections you might set up. The presence of liquids may likewise welcome consumption of the equipment, with a further risk of introducing toxins. storage tanks are likewise required for the fluids, and residues must be disposed of toward the finish of the operational process.

#4. Safety: ( Hydraulic and Pneumatic )

Taking into account hydraulics and pneumatics in the industrial environment, pneumatics is without a doubt the more secure option. A leakage of compressed air won’t cause contamination, since air isn’t poisonous or corrosive, albeit different gases utilized in independent or compact hardware might be unsafe. Compressed air doesn’t, for the most part, represent a risk of fire and it will not detonate, however, the forcible escape of air through mechanical failure might cause physical injury.

Hydraulics, then again, are generally in danger of possibly dangerous risks. Indeed, even water can cause damage assuming that it’s adequately hot to scald. Other fluid media, for example, oil, ethylene glycol, plasma, and liquid fabricated materials might be corrosive or potentially toxic. The liquid media might be ignitable and require additional safety precautions, and utilized oil or fluids should ultimately be drained and securely disposed of. Hydraulic systems incorporate fewer mechanical parts, yet these might be dependent upon corrosion and potential component failures.

#5. Energy: ( Hydraulic and Pneumatic )

The two systems as a rule require an input of electrical power to drive them, and a pneumatic system needs the constant running of a compressor to provide the compressed air. The air supply can’t be recycled and requires constant replenishment so energy consumption in this respect might be high. Any air leakage will likewise waste energy in the system.

You likewise need to consider the way that pneumatic systems lose energy through heat produced by the compression process, however, there are a few measures that can be taken to make your system more energy-proficient. Luckily, the air is still free to charge, so there is a compelling reason need to expand energy in obtaining, replenishing, or disposing of byproducts.

Hydraulic fluids can utilize a similar oil or water again and again after the initial start-up. provided you have a decent filtration system and keep it appropriately maintained, a hydraulic system can be very energy-efficient in the long run. Nonetheless, electrical power is still generally required to drive the pump, and a large part of the energy consumed by the pump is wasted. This is on the grounds that the fluid medium is in constant circulation to keep up with system pressure, despite the fact that only short periods of actuation might be required to drive the application. The more viscous the fluid medium, the more energy will likewise be required to move it. Be that as it may, significant improvements are being accomplished, with technological progressions including various sorts of pumps and the potential of modulating drives.

#6. Complexity: ( Hydraulic and Pneumatic )

Hydraulic systems normally have fewer moving parts and might be effectively controlled with push buttons and simple levers. On the other hand, hydraulics rely upon complex engineering that requires a system of valves and hoses, as well as a pump powered by an outer energy source and a tank for storage of the fluid medium. It is feasible to install a centralized power unit in a manufacturing plant to control a few different hydraulic applications. The newer development is installing much better systems for overseeing velocity, pressure, and power.

Pneumatic system designs are likewise very simple, and operate at a much lower pressure, so their component parts might be produced using less expensive and less perplexing materials. Since the fluid medium isn’t corrosive or combustible, precautionary measures needn’t bother with to be worked against these safety hazards. Technological advances have increased the range of purposes for pneumatic systems, with scaling down and new materials assisting with diminishing load as well as bulk.

#7. Maintenance: ( Hydraulic and Pneumatic )

Pneumatic systems are cleaner and simpler to keep up to maintain than hydraulic ones since the fluid medium is air. A customary schedule of inspection and maintenance support is normally all that is expected to keep a pneumatic system running, for example checking the seals and ensuring there is no leakage of air. The air should be cleaned of toxins, and one of the main maintenance procedures is the cleaning and normal replacement of the filter-controller-lubricator unit.

With hydraulic systems, the main concern is corrosion. Except if you’re able to install pipes made of non-corrosive material, for example, electrified steel, standard observing will be required to assess what lines are being affected by the fluid medium. Water may cause oxidation, and oils or different media might leave deposits that will cause corrosion. Regular checks and replacements will be required for critical components like seals, hoses, and valves.

Conclusion

The flexibility of airflow, and its accuracy is used, go with pneumatic an obvious decision for such applications as medical tools, dental drills, and small-scale advanced mechanics. Pneumatic are best utilized in specific conditions where hygiene or green practices are central, however, they are for the most part unreasonable for large-scale or heavy-lifting duties. Hydraulics are great for such high-force applications and are in many cases tracked down in development or mining conditions. They give consistent force and power, despite any varieties in speed, and keep up with positional unbending nature. Despite the fact that hydraulics and pneumatic work on the same principles, the two kinds of systems have totally different attributes, highlights, and applications. For more information on pneumatic, hydraulics, or other equipment, go ahead and counsel our extra data assets.

Content Source: – nexflow, rowse

Image Source: – britannica, tameson