Gate Valve Types and Parts

Introduction

Types of Gate Valve:- Gate valve is the simplest type of valve also known as the On/Off valve or Knife valve or slide valve. Gate valve is designed to operate either at the fully open or fully closed condition. When the valve is fully open or the gate is in open condition there is very negligible resistance to the flow of water and when it is in closed condition or the gate is closed it will restrict the fluid flow. They are used in both the above-ground and underground applications. As the gate valve can only work on either fully open or closed conditions so it is very bad at flow control. Now, let’s talk about different parts of the Gate valve.

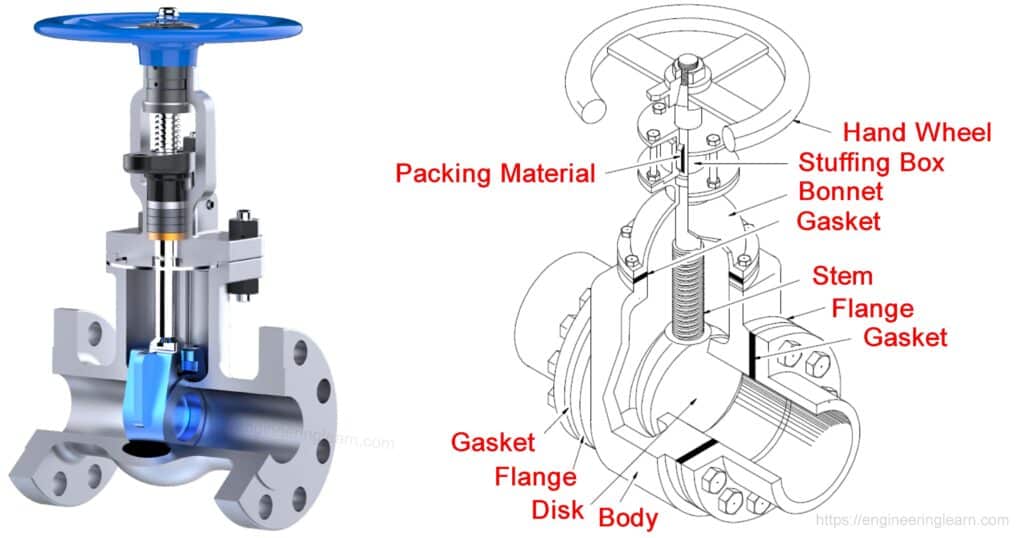

Gate Valve Parts

- The valve body is the primary part of the valve which holds everything together. Mostly it is connected to piping through flange and gasket. It is the pressure boundary of the valve.

- The valve bonnet is the second boundary of pressure. It is connected with a valve body with bolts or flange.

- The valve trim collectively stems, seat, and the disk is known as valve trim. Valve performance is dependent on seat and disk arrangement.

- The seat and disk are the most important part of the gate valve. It contains a gate-type disk and seat which fits the disk tightly.

- The stem connects the actuator and disk in the gate valve. It opens and closes the disk and seat arrangement. Two types of the stem are available one is rising which rises when we open the valve and the other is non-rising which has no vertical motion.

- Valve Actuator is a manual wheel which operates stem and disk arrangement.

Gate Valve Types

Now, we know about the basics of the gate valve and parts of the gate valve. In close condition, the fluid pressure is on the gate, and in the high-pressure condition, it causes valve failure. The Gate valve is used in many industries like pharmaceutical, Oil & Gas industry, and marine industries. Let’s talk about different types of gate valves.

1. Solid Wedge Gate Valve: ( Types of Gate Valve )

It is a very popular type of gate valve. It is useful for almost all materials. Here wedge-type disk is used and fitted on the seat. It is used for moderate pressure conditions but not useful for the high-pressure condition because it sticks due to high-pressure cause leakage. Sometimes due to thermal expansion seat does not open and gets jammed. This phenomenon is called thermal binding.

2. Parallel Disk or Split Gate Valve: ( Types of Gate Valve )

This type overcomes the problem of thermal binding due to its freedom of movement. Here two disks and seats are kept together by spring. It is used for low and medium pressure applications.

3. Flexible Wedge Gate Valve: ( Types of Gate Valve )

It consists of a small cut on the disk which fits on the seat. Due to this cut, we get leakage-free alignment between seat and disk. It is used in steam applications.

4. Non-Rising and Rising Gate Valve: ( Types of Gate Valve )

In the rising gate valve, the stem will go up when we open the gate valve and goes down on closing. In a non-rising valve, no verticle movement occurs. It is used when we have less space available.

Advantages of Gate valves

- Offers less resistance to fluid

- It can be used with slurries and viscous liquids

- Easy to maintain

Disadvantages of Gate valves

- Opening and closing is time-consuming

- Very bad at throttling

So, this is all about the Gate valve. Thank you!