Differential Gearbox: Definition, Types, Components, Functions, Materials, Principle, Working Process & Advantages

Differential Gearbox Introduction:

Differential Gearbox: Definition, Types, Components, Functions, Materials, Principle, Working Process & Advantages: – Differential gears form a group of gears that transfer power from the engine to the wheels while enabling them to rotate at varying speeds. With back tire drive, the differential is between the rear wheels, which are associated or connected with the transmission by the driveshaft. The differential has no impact when the vehicle is moving straight. The effect happens when the vehicle is trying to make a turn, bringing about the wheel moving at an alternate speed.

What is a Gearbox?

The gearbox is a component that empowers the torque to change or changes the rpm speed of the engine. The input shaft interfaces with the engine on one side, and the gearbox on the other end. The output shaft delivers a specific torque or force given by the different gear proportions present in the gearbox.

What is a Differential Gearbox?

The differential gearbox is one of the essential components of any car, if we talk as per auto mechanics, gear arrangement that permits power from the engine to be transmitted to several driving wheels, dividing the force equally between them yet permitting them to follow ways of various lengths, as while turning a corner or navigating an uneven road. Gearboxes are utilized in almost every industry right from power to marine and furthermore include agriculture, automotive, aviation, shipping, and so on.

There are various kinds of gearboxes accessible for different purposes. These gearboxes are constructed from different materials relying upon their end use and the kind of industry they are being utilized in. The product has various industrial applications for providing high torque and smooth speed reduction. These gearboxes are likewise manufactured keeping specific specifications, which will likewise fluctuate contingent upon the application.

Different Types of Differentials

- Conventional type.

- Non-slip or self-locking type.

- Double reduction type.

1. Conventional Type

Conventional type differential delivers a similar torque to each rear wheel. Assuming that any of the wheels slips because of any reason the wheel doesn’t rotate and the vehicle doesn’t move.

2. Non-slip or Self-Locking Type

Non-slip or self-locking type differential overcomes this disadvantage. Its construction is like that of a conventional type differential. Be that as it may, two sets of clutch plates are provided additionally. Likewise, the closures of planet shaft cage.

3. Double Reduction Type

Double or twofold type differential gives further speed reduction by extra gear. This kind of differential is utilized in heavy-duty automobiles which require larger gear reduction between wheels and engines.

Purpose of Differential Gearbox

Exactly when a vehicle is taking a turn on the curve of the road, external wheels ought to travel a more prominent distance when compared to internal wheels. Presently suppose in the event that a vehicle has a solid rear axle with next to no special mechanism, there is a more prominent possibility of wheel skidding. To stay away it is important to install some mechanism that reduces the speed of the inward speed and increase the speed of the external wheel so that speed of both wheels matches with one another very much like a vehicle is going straight forward, such devices are called a differential. Differential gear helps both wheels.

- To prevent wear of tires always prefer the differential gear to rotate at a different speed.

- To rotate the internal wheel less distance contrasted with an external wheel.

Functions of Differential Gearbox

At the point when a four-wheeler takes a turn, the external wheel turns faster than the internal wheel. Consequently, there is relative movement between the inward and external wheels. There is a transmission of power from the engine to drive wheels. Be that as it may, while taking a turn both the drive wheels don’t need the same power, for instance, while taking a right turn, the outer wheel requires more power than an inward wheel. Aside from permitting the drive wheels to run at various rpms, the differential gearbox is likewise utilized for speed reduction while transmitting the torque.

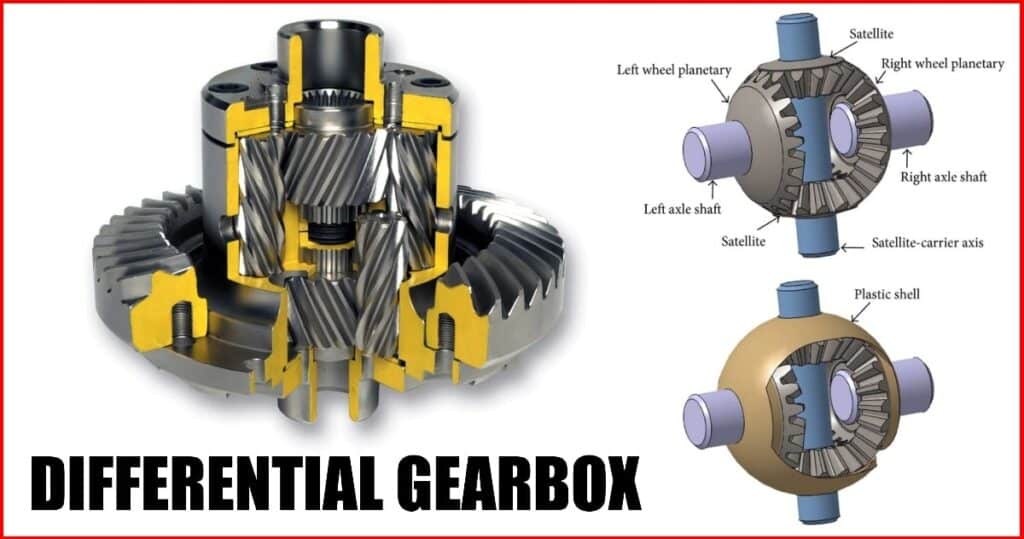

Principle of Differential Gearbox

If a vehicle travels in a straight line, the two back wheels turn precisely at a comparable speed, and there is no relative movement between them. In any case, when the vehicle takes a turn the outer wheel travels a longer radius than the inner wheel for example there is relative movement between the two rear wheels. The external wheel turns at a faster speed and covers a larger distance than the internal wheel. The inner wheel makes a larger angle than the external wheel. In this way, the vehicle negotiates the turn safely.

What is the Need for a Differential Gearbox?

At the point when a vehicle travels in a straight line, the two rear wheels turn out and about precisely at a similar speed and there is no relative movement between the two rear wheels. Be that as it may, when a vehicle takes a turn the external wheel travels on a longer radius than the internal wheel. The external wheel turns faster than the internal wheel for example there is relative movement between the two rear wheels.

In the event that two rear wheels are rigidly fixed to a rear axle, the internal wheel will slip, which will cause rapid tire wear, steering difficulties, and poor road holding. In this manner, there should be some device, which will divide the input torque of the transmission system between two rear axles. Differential fills this need or purpose.

Materials Used in the Differential Gearbox

Gearboxes are constructed from a variety of materials. A portion of the popularly utilized materials are mentioned below: –

The ratio of a bevel gearbox can be determined by dividing the quantity of teeth in the larger gear by the number of teeth in the more modest one. These gearboxes generate the varying levels of torque and can likewise be customized to suit individual requirements.

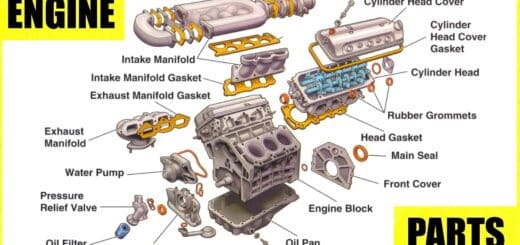

Components of Differential Gearbox

- Drive pinion or Bevel pinion

- Ring gear or Crown wheel

- Differential case

- Differential side gear or Sun gears

- Differential pinions (or) Planet gears

- Axle shafts or half shafts

- Pinion shaft or Cross pin

Below is the description that shows the basic parts of the type of differential used in different vehicles: –

On the inner ends of each axle, a smaller bevel gear called differential side stuff is mounted. Two bevel gears are assembled to work both driving and driven shafts at an angle of 90°. Two-wheel axles and differential side gears are mounted with a differential case. The differential case has a bearing that rotates two axle shafts. Then, at that point, the two pinion gears and their supporting shaft, called pinion shafts, are fitted into the differential case. Then, at that point, the pinion shaft meshes with the two differential side gears connected to the internal ends of the axle shafts.

If we talk about the differential case the ring gear is dashed or bolted. The ring gear rotates the differential case. At last, the drive pinion is mounted. The drive pinion is collected with the differential housing called differential case. The driver shaft is connected or associated with the drive pinion by a universal joint and it meshes with the ring gear. Thus, the drive pinion is rotated when the drive shaft turns. In this manner, the ring gear is rotated.

What is the Location of the Differential Gearbox?

In Front-engine front-wheel-drive layout – the differential is located at the front close to the gearbox.

In the Back engine rear wheel drive layout – In this, the differential is located at the back close to the gearbox.

Four wheels drive layout – In this case, the differential is located at the front as well as rear

Front engine rear-wheel-drive layout – it is located at the rear in between two half shafts.

Working Process of Differential Gearbox

A) When Running Straight

When the power comes from the propeller shaft to the slant pinion which drives the crown wheel it enables vehicles to move in a straight line. Then, at that point, it is carried to the differential cage wherein a bunch of planet pinions and sun gears are located. From the sun gear, it is transmitted to the road or street wheels through axle half shafts. For this present circumstance, the crown wheel, differential enclosure, planet pinions, and sun gears all turn as a single unit and there is no general movement between the sun gear and planet pinion. The planet pinions don’t rotate about their own axis. The road wheels, half shafts, and sun wheels offer a similar resistance from being turned and the differential gearing doesn’t operate. Both the road wheels turn at a similar speed.

B) When Taking a Turn

Right when the vehicle feels free to go ahead, the internal wheel encounters resistance and will overall rotate in the other direction. Because of this the planet pinions start rotating about their own axis and around the sun gear and transmit more rotary movement to the external side sun gear. With the goal that the outer sun gear rotates quicker than the inner sun gear. Thusly the outer road wheel runs faster than the inner road wheel and covers a more distance.

Advantages of Differential Gearbox

- It is safe or impenetrable to EM (Electromagnetic) obstacles as differential signs are transmitted on balanced lines.

- Differential gearbox helps in limiting electronic crosstalk.

- Both driving wheels can turn in a similar direction at a similar speed.

- Both driving wheels can rotate in a similar direction at various speeds.

- Both driving wheels can turn the other way at a similar speed.

- Both driving wheels can turn the other way at an alternate speed

When should you Replace the Differential Gearbox?

Gearbox and Differential failures for the most part don’t happen coincidentally. These drive train parts to a great extent fail after some time, and hence identifying the start of these mechanical issues and remedying them before they take the vehicle off-road could set aside both time and cash.

The most common indicators that could recommend the gearbox, is defective are mentioned below: –

- Error codes and warning lights appear on the dashboard in the cabin while driving.

- A bump or juddering noise when it is an early sign of changing gears.

- If a clicking or knocking noise is coming then it suggests the gearbox is defective.

- Vehicle shudders under acceleration.

- If you notice any strong burning smell coming from around the gearbox then it indicates the gearbox is defective and you need to replace it.

- Trouble in finding the gates for the gears can demonstrate a developed issue with the gearbox.

Conclusion

The differential gearbox is situated in the center of the drive axle, where its functional capability is to ensure that the two wheels can turn at various speed and velocities and speeds while driving through curves, while in any case having the very same propulsive power. The torque of the motor is constantly divided in a decent proportion. Internal combustion engines operate at different measures of power and torque. In the event that the gearbox was missing, the car would slow down from a standstill or when a specific measure of resistance is offered to the vehicle. The engine actually runs at a high speed when compared with the wheels.

Image Source: – id-workz, researchgate