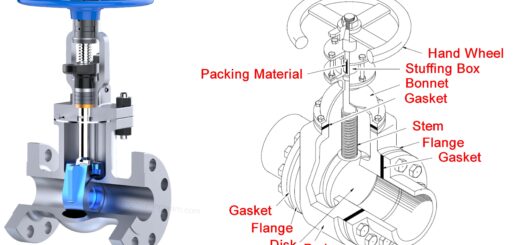

3 Types of Fits: Clearance Fit, Interference Fit, Transition Fit [Complete Guide]

![3 Types of Fits: Clearance Fit, Interference Fit, Transition Fit [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2021/11/Fits-1024x539.jpg)

Introduction

3 Types of Fits: Clearance Fit, Interference Fit, Transition Fit :- There are various types of fits in mechanical engineering which are designed in various circumstances. Three types of fits used in the products of manufacturing according to the ISO.

Different Types of Fits

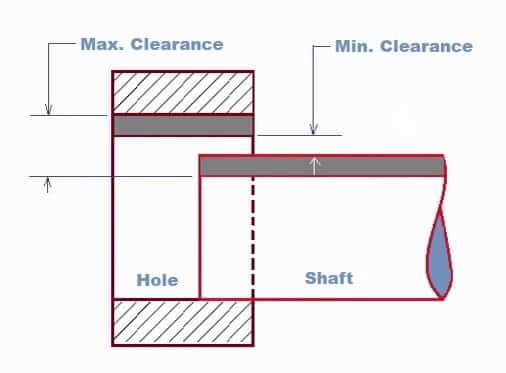

A) Clearance Fit (HOLE > SHAFT): ( Types of Fits )

Clearance fits are ideal for using when loose mating and free movement of the components are required. Thus, they are well suited for the products in which components are required to slide in and out with ease. The shaft in clearance fit are smaller than hole which gives two condition:

- Maximum clearance where the diameter of the shaft is minimum while the diameter of the hole is maximum.

- Minimum clearance where the diameter of the shaft is maximum while the diameter of the hole is minimum.

Clearance fits are divided in five different categories which are based on their clearance.

1) Loose Running Fit

Loose running fit are the clearance fit in which clearance is largest and they are well suited for the work in which accuracy is not important.

Application in engineering: Fits which is exposed to dust contamination, mechanical and thermal deformation, corrosion. Latches, pivots etc.

2) Close Running Fit

Close running fit are used for the work in which small clearance is required with regard to accuracy. These fits are good for sustaining medium pressure and speed.

Application in engineering: Sliding rods, machine tools, machine tool spindles etc.

3) Free Running Fit

Free running fit are used for the work in which movement of components with less accuracy is required. They provide space for movement with heavy plain bearing pressures, high running speeds and heave temperature fluctuations.

Application in engineering: Free running fits are used when oil lubrication is required to maintain. For example: Plain bearing fits and shaft with small rotational movement.

4) Locational Clearance Fit

Locational clearance fit are used for the works in which minimal clearance with very high accuracy is required. Assembly do not require any force and mating parts can slide and turn freely with the use of lubrication. For stationary parts they provide snug fit.

Application in engineering: Guiding of shafts, roller guides etc.

5) Sliding Fit

Sliding fit is used for the work in which small clearance is required with high accuracy. So, the parts where sliding fit are used can slide and turn freely.

Application in engineering: Sliding gears, guiding of shafts, slide valves, clutch discs, automobile assemblies, parts of machine tools etc.

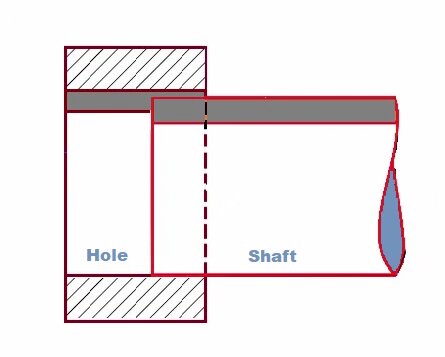

B) Transition Fit (HOLE = SHAFT): ( Types of Fits )

Transition fit falls in between interference and clearance fit and it is very well suited for accuracy work like for aligning the mating component required to join with high precision. Transition fit are also known as push or slip fit. Transition fit have high clearance as compared with interference fit. But the clearance does not provide surety of movement in joint. Therefore, depending upon the situation transition fit gives interference fit or clearance.

Transition fits are further divided into two categories:

1) Fixed Fits

Fixed fits provide small interference or small clearance and by using light force assembly.

Applications in engineering: Armatures on shafts, Driven bushes etc.

2) Similar Fits

Similar fits provide small interference or leaves small clearance and by using rubber mallet assembly is obtainable.

Applications in engineering: Gear, hubs, bearings, pulleys etc.

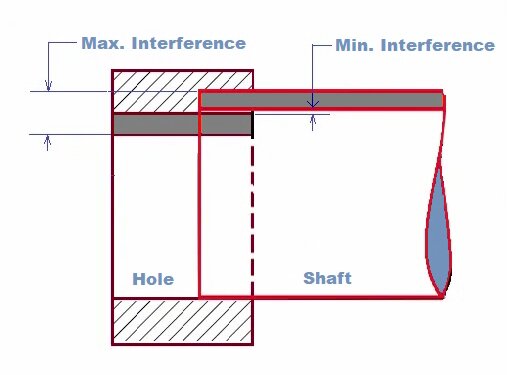

C) Interference Fit (HOLE < SHAFT): ( Types of Fits )

Interference fit are also known as friction fit or press fit and they have a fastening of two components by pushing both of them with each other. The fastening can be done by various mechanisms and need substantial force for coupling and uncoupling the components. This mechanism also find out various categories of interference fits for use. They also help in securing relative position of hub and shaft at the time of rotation also which results this type of fits excellent for transmitting the rotational power as well as speed.

In case of interference fit, the difference between the hole minimum size and shaft maximum size is maximum interference. And the difference between the hole maximum size and the shaft minimum size is the minimum interference.

Interference fits are further divided into three categories:

1) Forced Fit

They are high interference fit. In forced fit, the assembling of components need freezing the shaft and heating of the parts with hole so the disassembling results in broken parts.

Applications in engineering: Gears, shafts etc.

2) Press Fit

Press fit have minimum interference and the assembling is done by cold pressing.

Applications in engineering: Bushing, hubs, bearing etc.

3) Driving Fit

Driving fit are more important interference fit than the press fit because they require high assembling force for cold pressing and a another way is by the use of hot pressing.

Applications in engineering: Permanent mounting of gear, bushes, shafts etc.

Image Source:- extrudesign, ques10