What is Lathe Machine? Types of Lathe Machine & Their Uses [Complete Guide]

![What is Lathe Machine? Types of Lathe Machine & Their Uses [Complete Guide]](https://engineeringlearn.com/wp-content/uploads/2021/10/Lathe-Machine-1024x539.jpg)

Introduction of Lathe Machine

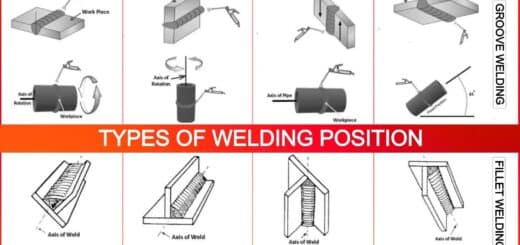

Types of Lathe Machine and Their Uses [Complete Guide] :- Lathe machines are used in shaping different work-pieces by removing metal from the surface of the work piece in order to get desired size and shape. Lathe machines are employed in wide range of applications such as wood turning, metal working, thermal spraying, glass working, metal spinning and parts reclamation. There are many different operations which can be performed using lathe machines such as cutting, sanding, drilling, knurling. The type of lathe machine required completely depends upon the requirement and material which is being shaped. ( Operation of Lathe Machine )

Types of Lathe Machine

1. Turret Lathe Machine: ( Types of Lathe Machine )

Turret Lathes are also known as capstan lathe machine. These machines are used for duplicated parts of high volume. Various operations performed by the turret lathes are facing, turning, reaming and boring. They have hexagonal turret which is mounted on saddle instead of tailstock. In this hexagonal turret various tools can be fixed which results in carrying out multiple operations on work piece. After every operation the turret is rotated and this leads to mass production of interchangeable parts using a single machine.

They are well suited for the sequential operations to be performed on work piece. The use of single machine for various operations can save time as well as reduces error. They are very effective for mass production of huge quantity of parts and they are the enhanced version of engine lathe machines. Turret lathe also contain three tool posts but they need huge floor space in comparison to other lathe machines. They are generally used for huge jobs and the major advantage of using turret lathe is that they can be operated by even the less skilled operators. ( Types of Lathe Cutting Tools )

2. Speed Lathe Machine: ( Types of Lathe Machine )

It is also known as Wood Lathe and works at high speed. Speed Lathe is generally used in metal polishing, spinning and wood turning. They consist of high speed spindle which is used for making items such as baseball bats, bowls and various furniture parts. This lathe machine is simpler in comparison to other types of lathe machines. It contain tailstock, headstock and tool turret but does not have feed mechanism therefore the feed is operated manually. The speed of speed lathe machines is in between the range of 1200 rpm to 3600 rpm.

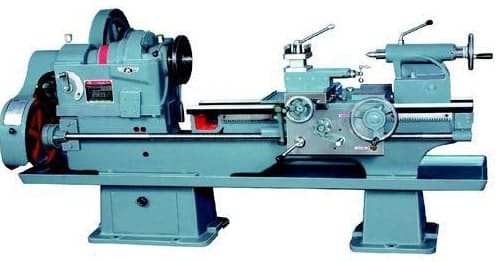

3. Engine Lathe Machine: ( Types of Lathe Machine )

Engine lathe machines were used in steam engine in 19th and 20th century but nowadays they are powered with individual motor drives. They are well suited for the manufacturing operations of various of metals. Engine lathe can perform operations such as facing, turning, knurling, threading and grooving. Engine lathe machines consists of saddle, bed, tailstocks and headstock etc. The tailstocks of the engine lathe machines are moveable and are used for supporting in knurling operations while the headstock is rigid. The cutting tool can be easily feed in both lateral as well as longitudinal directions by feed mechanisms.

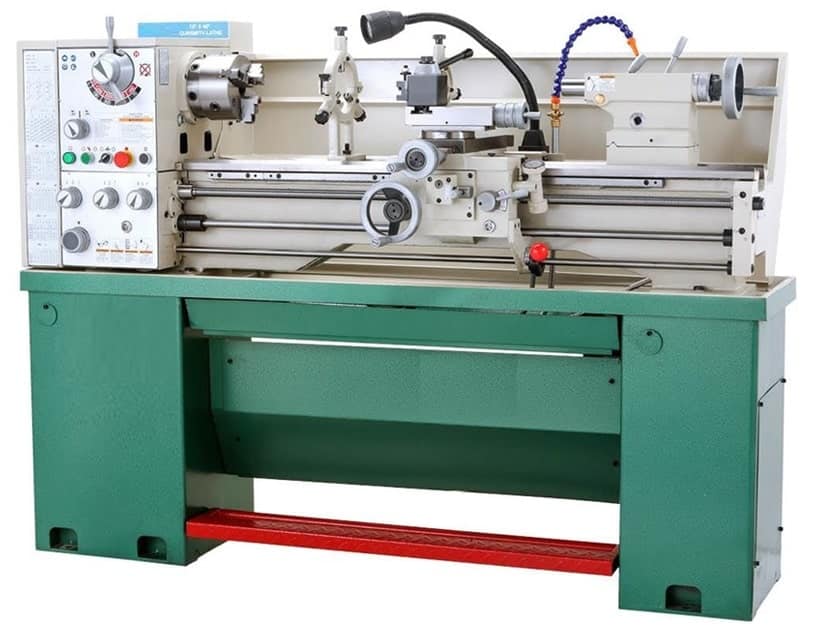

4. CNC Lathe Machine: ( Types of Lathe Machine )

In CNC Lathe, CNC stands for Computer Numeric Control, which provides high accuracy in very less time. They are made with same components with which the manual lathes are made that are spindle, tailstock, headstock, chuck, tool turret and centres. They have an additional important component which is CNC control panel. By using the control panel, CNC lathe machines are being used for providing input instructions as well as for running programs. They are used for wide range of applications such as aerospace, automotive etc. ( Types of CNC Machine )

CNC lathes are the commonly used lathe machines due to their higher accuracy and faster working. They are very advanced types of lathe. CNC lathe uses computer programming for controlling machine tool. When program is being fed in the computer then according to the program the operation is started with very high accuracy as well as high speed. Even a semi skilled worker can operate CNC lathe very easily after doing the initial setup. ( Components of CNC Machine )

CNC lathe is used also used for mass production just like turret and capstan lath. But turret and capstan lathes do not have programming fed system. The components manufactured by CNC lathe machines have very high accuracy in terms of dimensional tolerances.

5. Automatic Lathe Machine: ( Types of Lathe Machine )

These lathe machines performs work automatically. Standard lathes have a major disadvantage that they cannot be used for mass production while automatic lathe machine are best suited for mass production. They have a mechanism which is responsible for automation. Automatic lathe do not require changing of tool manually due to the automation function. Major advantage of using automatic lathe is that 4 to 5 machines can be operated by a single operator at a single time. Automatic lathe machines are heavy duty as well as high speed machines.

6. Tool Room Lathe Machine: ( Types of Lathe Machine )

Tool room lathe machines are used when high precision is required. Operations performed by the tool room lathes are turning, grinding, drilling, boring and reaming. Tool room lathes are well suited for tools which require precision and for other superior accuracy which can be achieved by engine lathe. In headstock, the gearbox is attached which leads to options of variation in speed ranging from low to high speed. They are usually operated on speed up to 2500 rpm. Their parts are similar to that of an engine lathe but built with more accuracy and arranged in proper sequence for high precision.

7. Bench Lathe Machine: ( Types of Lathe Machine )

These lathe machines are usually mounted over a bench. Bench lathes are small in size and they are used for less precision work. Their parts are almost similar to the speed lathe and engine lathe.

8. Special Purpose Lathe Machine: ( Types of Lathe Machine )

Special purpose lathe machines helps in executing specific types of functions which are otherwise not possible on standard or other lathe machines. Special purpose lathe machines are best suited for heavy duty production of identical parts. Wheel lathes, vertical lathes, multi spindle lathes, t – lathe, tracer or duplicate lathes, production lathes etc are some examples of special purpose lathe machines.

Wheel lathe machines are used for rail rods and machining journals. They are also used in turning the threads on the wheels of locomotives. T – Lathe machines are used in jet engine’s rotor machining. Axis of the headstock spindle and the axis of lathe bed are at right angle with each other in form of T.