13 Types of Wood Joints and Their Uses [with Pictures]

![13 Types of Wood Joints and Their Uses [with Pictures]](https://engineeringlearn.com/wp-content/uploads/2021/11/Wood-Joints-1024x539.jpg)

Introduction

Types of Wood Joints and Their Uses [with Pictures] :- Wooden joints are defined as the joints which are formed by sheets of wood with the help of nails, fasteners, pegs or glue. The main motive of wood joints is to provide stability, flexibility, durability, appearance etc. to the project. So, the joints should offer these characteristics. Some wood joints require fasteners, adhesive material, or binders while others use only the wood elements.

Types of Wood Joints

Many projects are made from wood like a house, a frame or even a small cabinet. All are made with the help of joints. So, here there are following types of wooden joints –

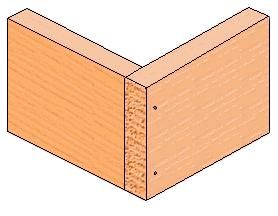

1. Butt Joint: ( Types of Wood Joints )

A butt joint is the traditional type of wood joint. Two different wood pieces simply sit side by side, with the butt of one work piece adjacent to the butt of another work piece. In this wooden joint the two pieces are not shaped or carved to lock into each other, and the fasteners like bolts & screws are mainly used to hold them together. In construction work, butt joints are mainly used to fix baseboards and window trims. It works as quick option when the speed of construction is more important than the final look.

2. Lap Joint: ( Types of Wood Joints )

Lap joint is also a popular joining method. The lap joint maybe a full lap or half lap. In a full lap joint, there is no material removed from either of the pieces to be joined, but in a half-lap joint, material is removed from both the pieces to obtain the joint thickness. It can be produced on two long-grains where the faces are joined with glue. The lap joint is the strongest joint, and also has the capacity to resist shear forces.

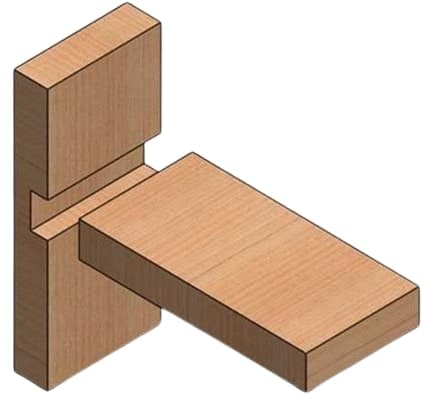

3. Bridle Joint: ( Types of Wood Joints )

Bridle joint is also a traditional joining method. It is also known as open tenon, open mortise and tenon, or tongue and fork joint. In this joint the through mortise is open on one side and forms a fork shape. These joints are mainly used in joining rafter tops, also used in scarf joints and occasionally used as sill corner joints in timber framing.

4. Dowel Joint: ( Types of Wood Joints )

Dowel joints are very strong and attractive joints. Dowel joint is also useful for increasing the stability of weaker wooden joints such as the butt joint. This type of joint is secured with a binding material and also a small piece of dowel. The dowel pin is butted against another piece of wood and makes a strong joint. Dowel joints are mainly used in making furniture. It is also used in carpentry work for joining two or more pieces of wood.

5. Cross Dowel Joint: ( Types of Wood Joints )

Cross dowel joint is same as dowel joint. The only difference is that in a cross dowel joint, a threaded metal dowel is inserted into a drilled slot. After that a screw is then inserted and tightened to create a pull effect. This joint is commonly used in factory made furniture.

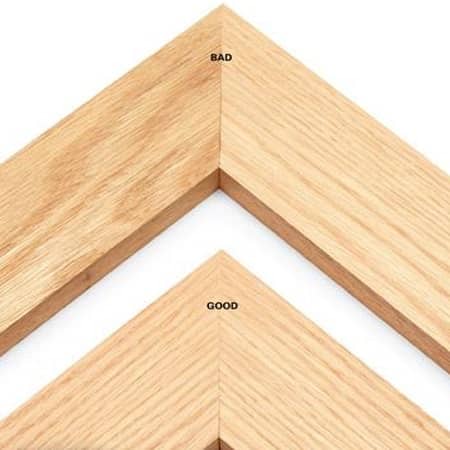

6. Mitre Joint: ( Types of Wood Joints )

A mitred butt joint is basically same as butt joint, but the variation is that, the two boards are joined at an angle. Mitre joint is the simple joints that require any form of cutting. It requires accurate 45° cutting angle. Mitre joint are mainly used for making frames, furniture, doors, windows etc.

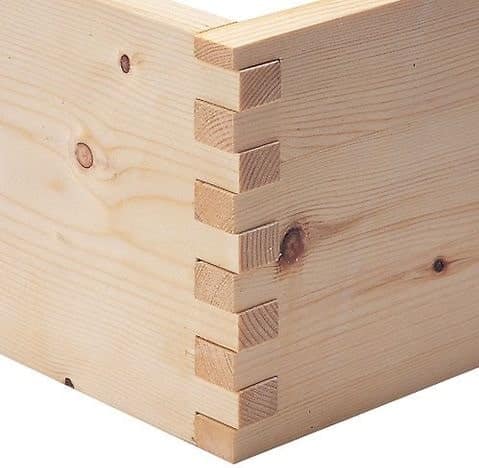

7. Box Joint: ( Types of Wood Joints )

A box joint is a wooden joint which is made up from cutting a set of sheets or profiles in two pieces of wood. These set of sheets are then connected perpendicularly with the aid of an adhesive. The glued box joint has a high surface area, this results the bond strong. Box joints are used for making boards and solid panels of wood, also used for joining wider slates. The joint does not have the interlinking properties as compared to dovetail joint, but it is easy to make and can be a mass product.

8. Dovetail Joint: ( Types of Wood Joints )

Dovetail joint is also a traditional technique used in wooden joint. This is a form of box joint where the fingers are locked together with diagonal cuts. Dovetail joints are known for their characteristics strength and resistance. It is traditionally used for joining wooden furniture.

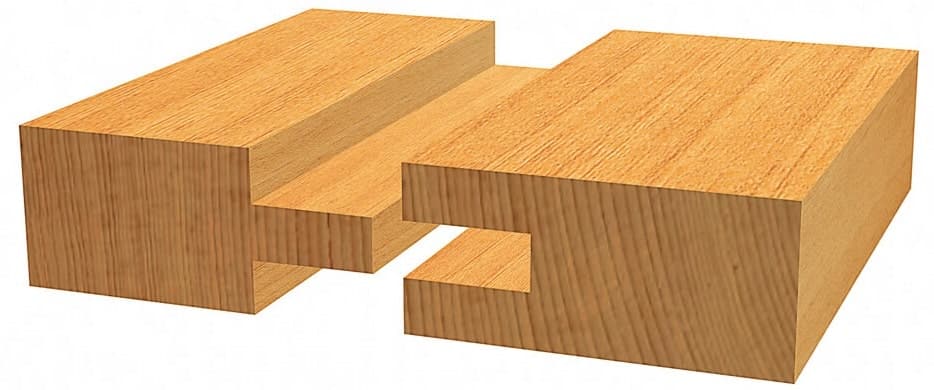

9. Dado Joint: ( Types of Wood Joints )

The dado joint is the strongest wooden joint. It is also called a housing joint or trench joint. A dado joint is made up of three-sided channel cut across the grain of one work piece. These joints are often used to build cabinets and bookshelves. Dado joints made using a table saw or router. These are often used to build cabinets and bookshelves.

10. Groove Joint: ( Types of Wood Joints )

A Groove joint is a slot or trench cut into a member which runs parallel to the grain. A groove joint is something same dado joint, which runs across the grain. Grooves joints are mainly used for making cabinets and other wooden work. Generally, grooves joints are used in panel construction and the bottom of drawers.

11. Groove and Tongue Joint: ( Types of Wood Joints )

A Groove and Tongue joint is a characteristic wooden joint which is joined edge to edge with two or more pieces of timber. It consist of a slot that moves down the entire length of the timber and which fits into the slot of tongue This groove and tongue joint creates a strong and durable joint that can be used as floorboards, lining boards, wood panelling and table tops.

12. Mortise and Tenon Joint: ( Types of Wood Joints )

The Mortise and Tenon joint is a classic wooden joint. These joints are in use since the early times of wooden work, and are still among the most effective and durable methods for joining the wood. The mortise and tenon joint is a very popular, strong and frequently-used joint for assembling a variety of projects where strength and reliability are required. The mortise and tenon is the strongest joint in wooden work.

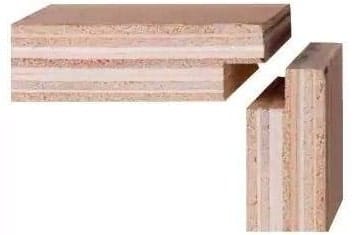

13. Rebate Joint: ( Types of Wood Joints )

The Rebate joint is something same as the butt joint but the main difference between this two is that one of the ends of the timber has a groove cut to create better holding strength. Even with the extra strength the joint is still fairly easy to construct and the appearance is also more effective as compared to a regular butt joint making it a better joint for carpentry or cabinet making.